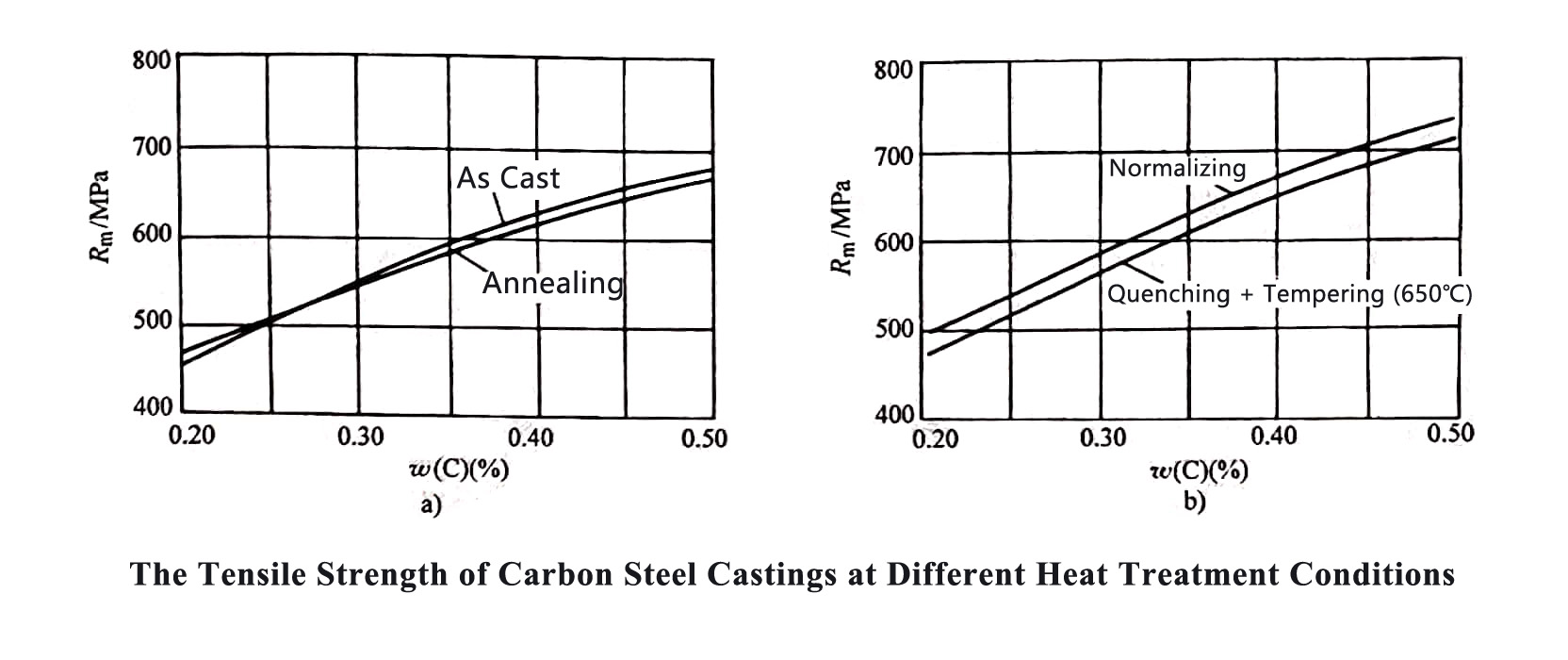

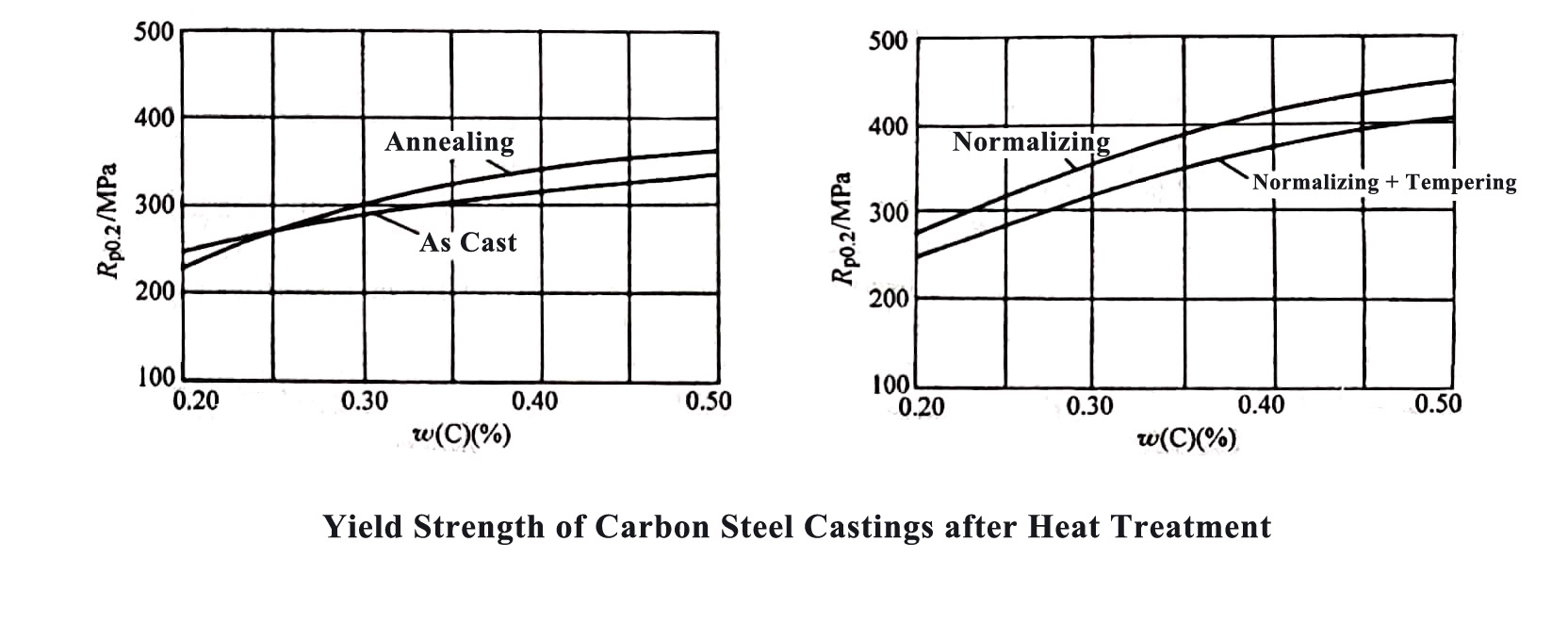

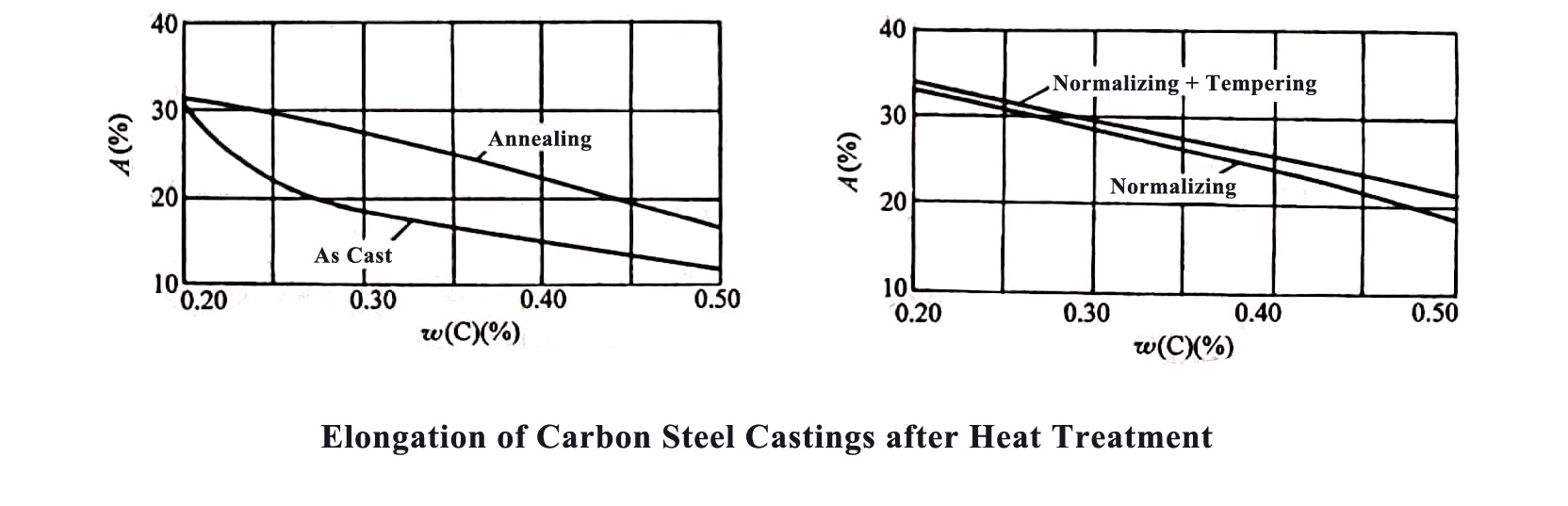

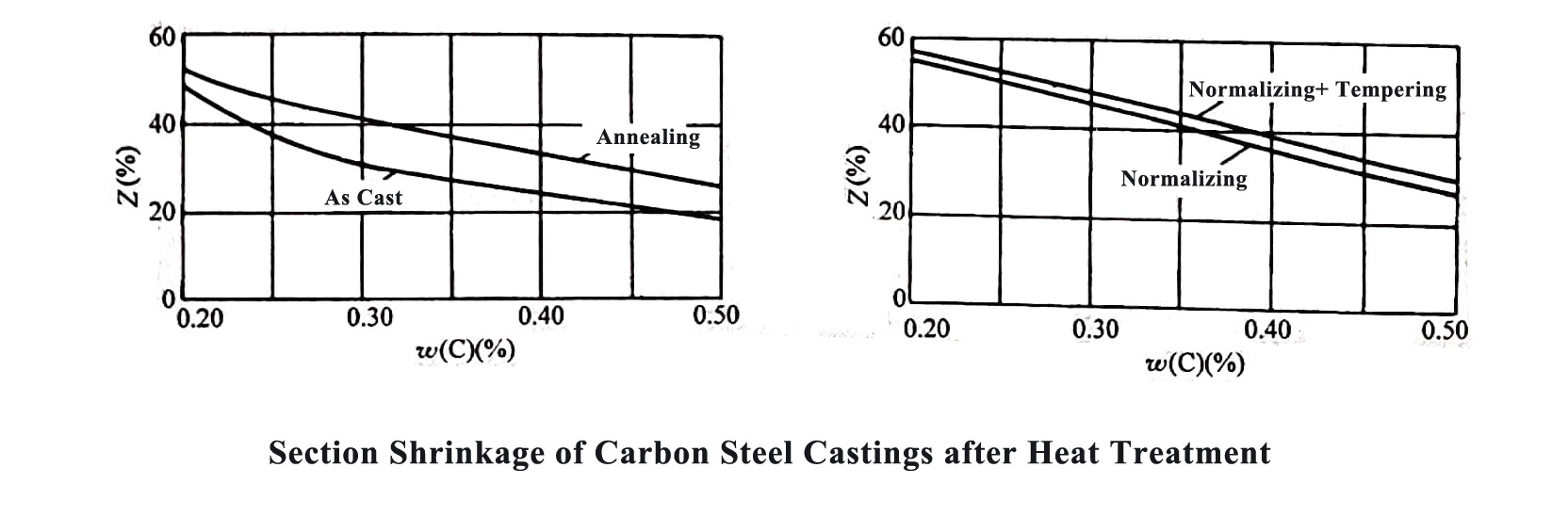

Izindlela zokwelashwa kokushisa ezivame ukusetshenziselwa ukukhishwa kwensimbi ye-carbon yilezi: ukudonsa, ukujwayelekile noma ukujwayelekile + ukushisa. Umthelela walezi zindlela ezintathu zokwelashwa kokushisa kuzakhiwo zemishini ye-cast carbon steel kuboniswa esithombeni esingezansi.

| I-Annealing Temperature kanye Nokuqina Kwe-Carbon Steel Castings | ||||||

| Ibanga le-Carbon Steel | Okuqukethwe kwekhabhoni / % | I-Annealing Temperature / ℃ | Isikhathi Sokubamba | Indlela Yokupholisa | Ukuqina / HBW | |

| Ukuqina Kwezindonga / mm | Isikhathi / h | |||||

| I-ZG200 - 400 | 0.10 - 0.20 | 910 - 880 | < 30 | 1 | Ukupholisa ku-620℃ ezithandweni bese kupholisa emoyeni | 115 - 143 |

| ZG230 - 450 | 0.20 - 0.30 | 900 - 870 | 133 - 156 | |||

| ZG270 - 500 | 0.30 - 0.40 | 890 - 860 | 143 - 187 | |||

| I-ZG310 - 570 | 0.40 - 0.50 | 870 - 840 | 30 - 100 | ukwanda kwehora elingu-1 / 30 mm | 156-127 | |

| I-ZG340 - 640 | 0.50 - 0.60 | 860 - 830 | 187-230 | |||

Izakhiwo zemishini yensimbi ekhonjiwe evamile ziphakeme kancane kunalezo zensimbi ekhonjiwe. Njengoba izinga le-undercooling ngesikhathi sokuguqulwa kwesakhiwo likhulu ngokuqhathaniswa, ubulukhuni buyoba buphakeme, futhi ukusebenza kwayo kokusika nakho kungcono.

| Ukujwayela kanye Nokuqina KweCarbon Steel Castings | |||||

| Ibanga le-Carbon Steel | Okuqukethwe kwekhabhoni (%) | Izinga lokushisa elijwayelekile / ℃ | Ukuthuthumela | Ukuqina / HBW | |

| Izinga lokushisa / ℃ | Indlela Yokupholisa | ||||

| I-ZG200 - 400 | 0.10 - 0.20 | 930 - 890 | 540 - 610 | esithandweni noma emoyeni | 126-149 |

| ZG230 - 450 | 0.20 - 0.30 | 930 - 890 | 540 - 610 | esithandweni noma emoyeni | 139-169 |

| ZG270 - 500 | 0.30 - 0.40 | 890 - 860 | 550 - 620 | esithandweni noma emoyeni | 149-187 |

| I-ZG310 - 570 | 0.40 - 0.50 | 890 - 850 | 550 - 650 | esithandweni noma emoyeni | 163 - 217 |

| I-ZG340 - 640 | 0.50 - 0.60 | 870 - 830 | 550 - 650 | esithandweni noma emoyeni | 187-228 |

Ukuze uthole ukukhishwa kwe-carbon steel enokuqukethwe okuphezulu kwekhabhoni kanye nezimo eziyinkimbinkimbi, ukuze kuqedwe ukucindezeleka okusele futhi kuthuthukiswe ukuqina, ukwelashwa kokushisa kungenziwa ngemva kokujwayelekile. Izinga lokushisa elipholile livamise ukuba ngu-550℃-650℃, bese lipholile emoyeni.

Lapho okuqukethwe kwekhabhoni kungaphezu kuka-0.35%, izingxenye zensimbi ye-carbon carbon nazo zingacinywa futhi zifakwe umoya (zicinywe + izinga lokushisa eliphezulu elilinganiselwe). Ukukhishwa kwensimbi encane ye-carbon kungacinywa ngokuqondile futhi kufakwe umoya esimweni sokusakazwa; izinsimbi ezinkulu noma eziyinkimbinkimbi ze-carbon steel kufanele zicinywe futhi zifudumale ngemva kokujwayelekile.

| I-Quenching and Tempering Temperature kanye Nokuqina Kwe-Carbon Steel Castings | |||

| Okuqukethwe kwekhabhoni % | I-Quenching Temperature / ℃ | I-Tempering Temperature / ℃ | Ukuqina Ngemva Kokushisa / HBW |

| 0.35 - 0.45 (Iqoqo Elincane) | 850 - 830 (Ukupholisa Emanzini) | 300 - 400 | 364 - 444 |

| 400 - 450 | 321 - 415 | ||

| 510 - 550 | 241 - 286 | ||

| 540 - 580 | 228-269 | ||

| 580 - 640 | 192-228 | ||

| 0.45 - 0.55 (Iqoqo Elincane) | 830 - 810 (Ukupholisa Emanzini noma Ngamafutha) | 550 - 630 | 220 - 240 |

| 450 | ≈ 269 | ||

| 550 | ≈ 248 | ||

| 650 | ≈ 228 | ||

| 0.30 - 0.40 (Inqwaba Yenqwaba) | 840 -880 (Ukupholisa Emanzini noma Ngamafutha) | 520 - 550 | 229 - 269 |

| 530 - 560 | 217 - 255 | ||

| 540 - 570 | 207-241 | ||

| 550 - 580 | 187-229 | ||

| 0.40 - 0.50 (Inqwaba Yenqwaba) | 820 - 840 (Ukupholisa Emanzini noma Ngamafutha) | 530 - 560 | 229 - 269 |

| 550 - 580 | 217 - 255 | ||

| 560 - 590 | 207-241 | ||

| 570 - 600 | 187-229 | ||

Isikhathi sokuthumela: Jul-23-2021