Ukulingisa okuqondile kubizwa nangokuthiukutshala imali. Le nqubo yokulingisa inciphisa noma ayinqamuki phakathi nenqubo yokulingisa. Kuyindlela yokusakaza enezinhlobonhlobo zezinhlelo zokusebenza, ukunemba okuphezulu kokulinganisa kokulingisa, kanye nekhwalithi ephezulu kakhulu yendawo. Ayikho ezimweni zokushisa okuphezulu kakhulu, futhi ifaneleka kakhulu ukusakaza izingxenye ezimbonini ezinemba okuphezulu njenge-aerospace nokuvikela izwe. Bekungeyokuqala ukusebenzisa indlela yokusakaza yensimbi engagqwali ukunemba ukuphonsa izindwani ze-turbine injini yayo ehamba phambili yomoya ngaleso sikhathi. Umkhiqizo oqediwe wanconywa yizo zonke izici, futhi le ndlela yakhuthazwa kabanzi. Insimbi engagqwali ukunemba ukunemba kuwubuchwepheshe embonini yokusungula, kodwa yehlukile embonini yendabuko yesisekelo ngoba inani elingeziweimikhiqizo yokusakaza enembileiphakeme.

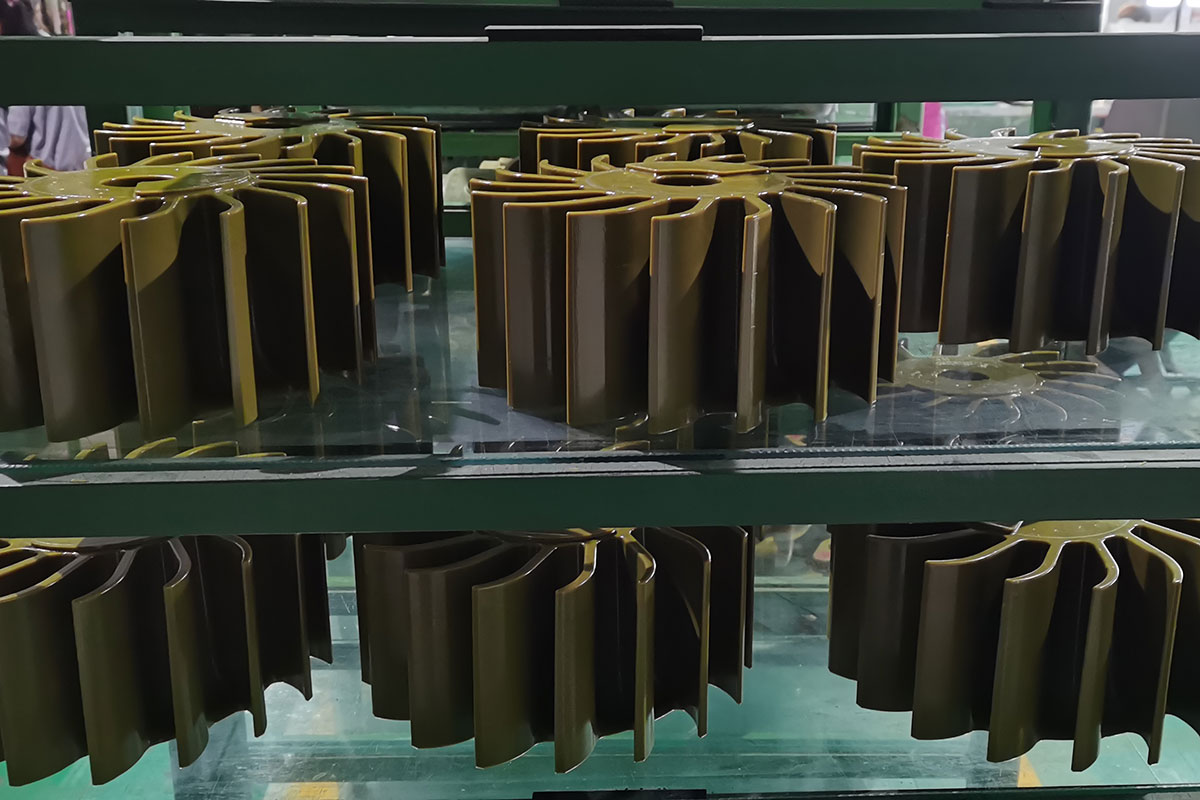

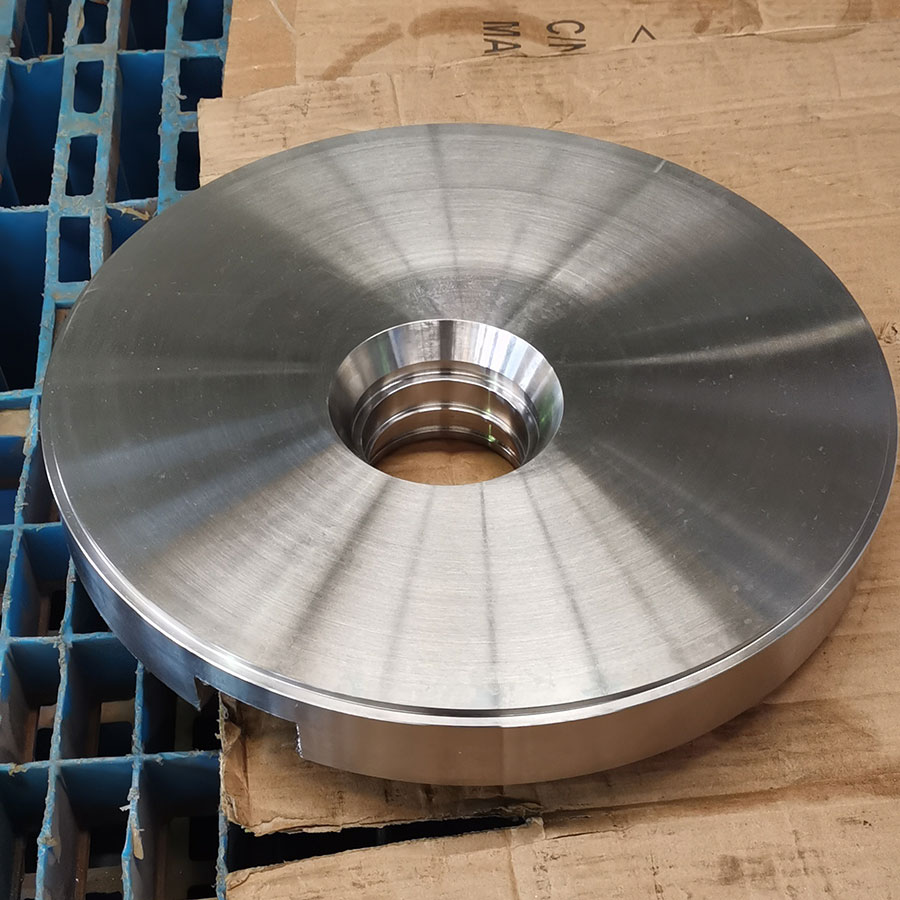

Inqubo ye-Silica Sol Shell

Inqubo yokwenza igobolondo le-silica sol ngokuvamile isetshenziswa embonini yokusakaza yezingxenye zenjini evuthayo yangaphakathi eyinkimbinkimbi. Ukugqoka okusetshenziswe kule ndlela kunokuzinza okungcono, akudingi inqubo yokuqina kwamakhemikhali, ukumelana nokushisa okuphezulu, futhi kunokumelana okungcono nokuguqulwa. Kodwa-ke, lobu buchwepheshe bubuye bube nalokhu kushiyeka okuthile, okungukuthi, ukufudumala kwesikhunta se-wax kumpofu, okungathuthukiswa ngokungeza ama-surfactants, kodwa kuzokwandisa ukutshalwa kwezimali ngezinga elithile.

Inqubo Yegobolondo Lengilazi Yamanzi

Le ndlela yasungulwa kusenesikhathi. Izwe lethu laphinde lethula lobu buchwepheshe obuvela eSoviet Union ngeminyaka yawo-1950 kanye nawo-1960. Le ndlela inezindleko eziphansi, ukusebenza okulula, kanye nezidingo zezinto ezingavuthiwe eziphansi. Izici eziyisisekelo zenqubo zisebenzisa i-parafini-stearic acid yesikhunta esinezinga lokushisa eliphansi, futhi isibophezelo enqubweni yokwenza igobolondo sisebenzisa ingilazi yamanzi, esetshenziswa kakhulu ekubunjweni kwensimbi engagqwali ngokunemba. Kodwa-ke, inkinga enkulu yale ndlela uma kuqhathaniswa nenqubo yokwenza igobolondo le-silica sol ukuthi ikhwalithi yangaphezulu ye-castings etholiwe iyisilinganiso futhi ukunemba kwe-dimensional kuphansi. Selokhu kwethulwa lobu buchwepheshe, kwenziwe intuthuko enkulu uma kuqhathaniswa, ikakhulukazi kulezi zici ezilandelayo:

1. Thuthukisa ukumbozwa kwegobolondo.

Intuthuko enkulu iwukwengeza inani elithile lobumba oluphikisayo embotsheni yangemuva yegobolondo, okuthuthukisa kakhulu amandla egobolondo, futhi ibona igobolondo elilodwa eligazinga nokudubula.

2. Ukwenziwa ngcono kwe-hardener.

I-hardener yendabuko isebenzisa kakhulu i-ammonium chloride, kodwa le nto izokhipha inani elikhulu legesi ye-ammonia ne-nitrogen oxide phakathi nenqubo yokuphonsa, ezongcolisa umkhathi. Ngakho-ke, isixazululo se-aluminium chloride sisetshenziswa esikhundleni, futhi i-aluminium chloride crystal iphinde isetshenziswe. Umphumela we-ejenti ufana nowe-ammonium chloride, kodwa eminyakeni yamuva nje, ukusetshenziswa kwe-magnesium chloride hardener kunenzuzo enkulu kakhulu mayelana nesivinini sokuqina kanye nezinsalela, ngakho-ke manje kuthambekele kakhulu ekusebenziseni i-magnesium chloride njenge-hardener. .

3. Igobolondo eliyinhlanganisela.

Ngenxa yokuthi ikhwalithi engaphezulu yegobolondo lengilazi yamanzi ineziphambeko ezithile, izingxenye eziningi zangempela ziphonswa ngendlela yokubunjwa kwenhlanganisela ye-multi-layer mold, esindisa izindleko ngakolunye uhlangothi futhi ithuthukise ikhwalithi yokubunjwa kolunye uhlangothi. isandla.

4. Ukuthuthukiswa kobuchwepheshe obusha.

Njengamanje, izinqubo ezintsha ezivuthiwe kufanele kube inqubo yokuzikhandla, isikhunta sepulasitiki esiyigwebu, ukubunjwa kwegobolondo elincibilikisiwe nezinye izinqubo. Lezi zinqubo zinezinzuzo eziholayo kwezinye izici, kodwa ukuthuthukiswa kwesikhathi esizayo kusazoheha abasebenzi besayensi nezobuchwepheshe.

I-Multi-technology Cross Use With Rapid Prototyping Technology

Idizayini kanye nokukhiqizwa kwesikhunta ohlelweni lokwenza isikhunta se-wax esinembayo sensimbi engenasici siyinkimbinkimbi futhi kudla isikhathi, kodwa ubuchwepheshe bokwenza i-prototyping ngokushesha bungavala lokhu kushiyeka. Ubuchwepheshe be-prototyping obusheshayo bubodwa abukwazi ukuqaliswa ngenxa yokulinganiselwa kwezinto ezibonakalayo, eziningi kangaka eminyakeni yamuva nje Ukusetshenziswa kobuchwepheshe be-polymer ukuthola ukuma okuyindilinga kokubunjwa, bese kwenziwa isikhunta se-wax, esisetshenziswa ekubunjweni kwensimbi engagqwali ngokunemba. Isibonelo, ubuchwepheshe bokumodela obuthathu-ntathu (SLA) kanye nobuchwepheshe obukhethiwe be-laser sintering (SLS). Lobu buchwepheshe bubili okwamanje ubuchwepheshe obuvuthiwe obusetshenziswa ngokuhambisana nokutshala imali. Ubuchwepheshe be-SLA bungahlinzeka ngokunemba okuphezulu kwe-dimensional, ikakhulukazi izingxenye. Ukunemba kwendawo yangaphandle, i-SLS, ngokwezinga elithile, izinto zokusetshenziswa zishibhe kancane, kodwa ukunemba nakho kunegebe elithile uma kuqhathaniswa nobuchwepheshe be-SLA, obufanele umsebenzi othile wokuphonsa onezidingo zezindleko. Kodwa-ke, kusadingeka ukunaka ukulawula inhlanganisela eyinhloko yobuchwepheshe be-prototyping esheshayo kanye nobuchwepheshe bensimbi engagqwali ukunemba ngokunemba ngesikhathi sokusetshenziswa, njengokucatshangelwa okuphelele kokulawulwa kwezindleko nokunemba kokusakazwa kwezingxenye, nokukhetha iphuzu elifanele lebhalansi ubuchwepheshe bokukopisha ngokushesha. kanye nobuchwepheshe bokutshala imali. Indaba eyinhloko yokuhlanganiswa kwezinto eziphilayo.

I-Multi-technology Ukusebenzisa Ngokuphambana Nobuchwepheshe Bekhompyutha

Idizayini yepulani nomsebenzi wokuthuthukisa ohlelweni lokunemba kwensimbi engagqwali kuwumsebenzi odla isikhathi futhi odla isikhathi. Eminyakeni yamuva, ngokuthuthukiswa okuqhubekayo kobuchwepheshe bamakhompiyutha, izimboni eziningi ezidinga inani elikhulu lokubala nokubala ngokunemba ziye zafaka umsebenzi wekhompiyutha, futhi ngokuhambisanayo nama-software wokubala ahlukahlukene athuthukisiwe, njengeProCAST, AutoCAD, AFSolid, Anycasting kanye nezinye isofthiwe. . Lawa ma-software angabala noma alingise inqubo yokuklama neyokusakaza yokusakazwa kwensimbi engagqwali ngokunemba. Uhlelo lwamanje lokuthuthukisa lungathuthukiswa ngokubalwa kwedatha. Ukuthuthukiswa kokulingisa kubambe iqhaza elihle ekukhuthazeni. Kodwa-ke, enqubweni yamanje yokusetshenziswa, siphinde sathola ukuthi kufanele sinake ukusebenziseka kokumodela kwesofthiwe yekhompiyutha kanye nemingcele ye-thermophysical yento ngokwayo. Isixazululo esihle salezi zinkinga singanciphisa kakhulu isikhathi sokuthuthukiswa kokusakazwa kwensimbi engagqwali ngokunemba.

Isikhathi sokuthumela: Oct-21-2021