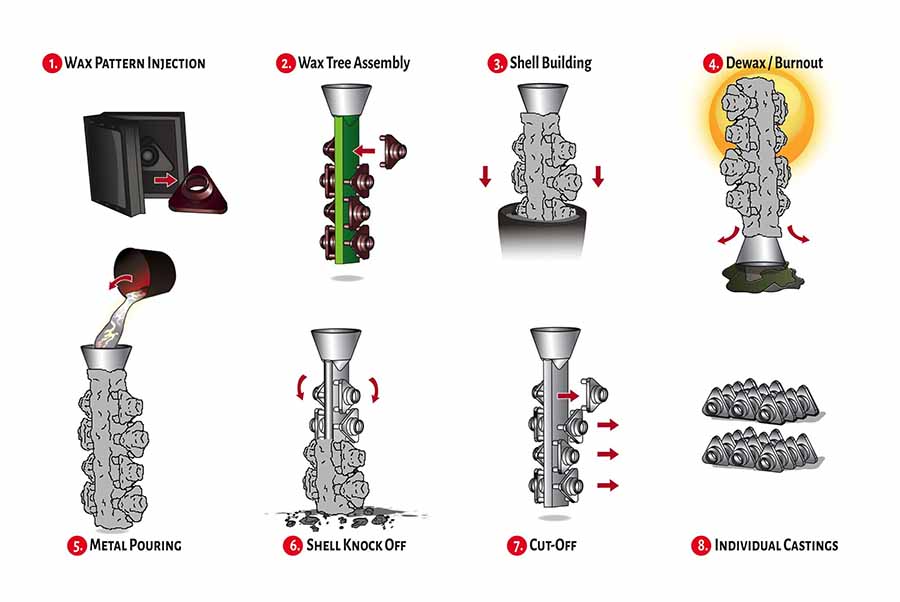

Ukutshala imaliisebenzisa amaphethini we-wax akhiqizwa amathuluzi akhethekile futhi ahlukile njengokubunjwa okudingekayo. Amaphethini we-wax (ama-replicas) azungezwe izendlalelo zezinto eziphikisayo eziboshiwe ukuze zakhe igobolondo eliqinile ukumelana nezinsimbi ezincibilikisiwe ezishisayo nama-alloys. Inqubo ye-de-wax izosusa i-wax ukuvumela imbobo engenalutho ukuze insimbi encibilikisiwe iwagcwalise ukuze akhe izingxenye zokuphonsa ezidingekayo. Yingakho ukukhishwa kwe-investimenti kubizwa nangokuthi inqubo yokukhipha i-wax elahlekile. Embonini yesimanje yokutshala imali, izinto eziboshiwe zibhekiselwa ku-silica sol kanye nengilazi yamanzi, engaqinisekisa ukuthi ingaphezuluukukhishwa kwezimali. Inqubo yokutshala imali ivame ukusetshenziselwa ukukhiqiza i-carbon steel castings, i-alloy steel castings,insimbi engagqwali castingskanye nokubunjwa kwethusi. Lapha kulesi sihloko, sizama ukwethula izinyathelo eziyinhloko zokutshala izimali.

Thuthukisa Ithuluzi Lokujova I-wax

Ngokuya kokulingisa okufunayo futhi kucatshangelwa isibonelelo sokusebenza ngemva komshini kanye nokuncipha okungase kube khona, onjiniyela endaweni yokufaka utshalomali kufanele badizayine futhi bakhiqize isikhunta ngensimbi (ephinde ibizwe ngokuthi "i-die") kanye namathuluzi okukhiqiza amaphethini we-wax.

Ukudala Iphethini ye-Wax

Kwesimanjei-wax casting foundry elahlekile, amaphethini we-wax ngokuvamile enziwa ngokujova i-wax ethuluzini lensimbi noma "kufa" ngemishini ekhethekile yokujova. Ngokusakazwa okuningi, ithuluzi le-silicon ngokuvamile lenziwa emfanekisweni womdwebi futhi i-wax iyajova noma ithululelwe emgodini owumphumela.

I-Wax Tree Assembly

Ngokuvamile akunamali ukwenza izingxenye ezincane ngesikhathi esisodwa, ngakho-ke amaphethini we-wax ngokuvamile anamathiselwe ku-sprue we-wax. I-wax ephakathi kwephethini (ama) ne-sprue ibizwa ngokuthi amasango, ngoba icindezela isiqondiso nokugeleza kwe-alloy encibilikisiwe esikhaleni esenziwe iphethini. I-sprue isebenza ngezinhloso ezimbili

- 1. Inikeza indawo ekhuphukayo ukuze ihlanganise amaphethini amaningi abe yisikhunta esisodwa, esizogcwaliswa kamuva nge-alloy

- 2. Inikeza indlela yokugeleza yengxubevange encibilikisiwe esikhaleni esidalwe amaphethini we-wax.

Shell Building

Isinyathelo esilandelayo kule nqubo ukwakha igobolondo le-ceramic elizungeze isihlahla se-wax. Leligobolondo ekugcineni lizoba isikhunta okuthelwa kuso insimbi. Ukwakha igobolondo, isihlahla sicwiliswa kubhavu we-ceramic noma i-slurry. Ngemuva kokucwiliswa, isihlabathi esihle noma sisetshenziswe endaweni emanzi. Isikhunta sivunyelwe ukuba some, futhi le nqubo iphindwe izikhathi eziningana kuze kube isikhunta se-ceramic egqinsiwe, esikwazi ukumelana nokucindezeleka kwensimbi encibilikisiwe nama-alloys ngesikhathi sokuthulula.

I-Dewax / Ukushiswa

Ngaphambi kokuthela insimbi esikhunjeni, i-wax isuswa ngokushisa igobolondo. Lokhu ngokuvamile kwenziwa ku-autoclave ye-steam-dewax, efana ne-cooker enkulu, yezimboni. Enye indlela ukusebenzisa i-flash fire oven, encibilika futhi ishise i-wax. I-wax ingaqoqwa futhi iphinde isetshenziswe ekwenzeni amaphethini e-wax alandelayo. Izikhungo eziningi zokutshala izimali zisebenzisa zombili izindlela ekhonsathini. Umlilo weflashi ushisa ingcina eyinsalela bese welapha igobolondo, ulungele ukwamukela insimbi encibilikisiwe nama-alloys.

Ukuthululwa Kwensimbi

Ngaphambi kokuba insimbi ithululelwe esikhunjini se-ceramic noma igobolondo, isikhunta sishiswa ngaphambili ekushiseni okukhethekile ukuvimbela ingxube encibilikisiwe ekuqinisweni noma ekuqandeni ngaphambi kokuba isikhunta sigcwaliswe. Ingxubevange incibilika enkomishini yobumba (ebizwa ngokuthi i-crucible) kusetshenziswa inqubo eyaziwa ngokuthi ukuncibilika kokungeniswa. Umsinga kagesi oyimvamisa ephezulu udala inkambu kazibuthe ezungeze ingxubevange, ikhiqize izinkambu zikagesi ngaphakathi kwensimbi (ama-eddy currents). Ama-eddy currents ashisisa ingxubevange ngenxa yokumelana nogesi. Lapho i-alloy ifinyelela ekushiseni kwayo okucacisiwe, ithululelwa esikhunjeni, futhi isikhunta sivunyelwe ukupholisa.

Shell Knock Off

Uma selipholile, okokusebenza kwegobolondo kukhishwa ensimbi kusetshenziswa izindlela zemishini ezifana nesando, ukuqhuma kwamanzi anomfutho ophezulu noma ithebula lokudlidliza. Ukususwa kwegobolondo nakho kungafezwa ngamakhemikhali, kusetshenziswa isixazululo esishisayo se-caustic se-potassium hydroxide noma i-sodium hydroxide, kodwa le ndlela iyaqedwa ngenxa yokukhathazeka kwemvelo nempilo.

Nqamula

Uma impahla yegobolondo isisusiwe, i-sprue namasango anqunywa ngesandla noma ngesaha le-chop, ukusika kwe-laser yethoshi. Izindawo zokusika zidinga ukugaywa zibe indawo enhle.

Ukusakaza Ngamunye

Ngemva kokuba izingxenye zisusiwe ku-sprue, futhi amasango asusiwe, indawo engaphezulu ingaqedwa ngezindlela eziningi ezifana nokudlidliza, ukuqedwa kwemidiya, ukubopha, ukugaya izandla, ukupholisha. Ukuqeda kungenziwa ngesandla, kodwa ezimweni eziningi kuyazenzakalela.Izingxenye zokusakazabese ziyahlolwa, zimakwe (uma kudingeka), zipakishwe futhi zithunyelwe. Ngokuya ngohlelo lokusebenza, izingxenye zokutshala imali zingasetshenziswa "kumumo wazo wenetha" noma zidluleimishiningokunemba kwezindawo.

Isikhathi sokuthumela: Jan-18-2021