Insimbi engagqoki (noma ukumelana nemihuzuko) isho insimbi ecijile enokumelana okuhle nokugqokwa. Ngokusho kokwakheka kwamakhemikhali, ihlukaniswe yaba insimbi engagqwali, i-alloy ephansi kanye ne-alloy wear-resistant cast steel. Kunezinhlobo eziningi zensimbi ezingagugi, ezingahlukaniswa cishe zibe yinsimbi ephezulu-manganese, insimbi eqinile eqinile ephakathi nendawo ne-alloy, insimbi ye-chromium-molybdenum-silicon-manganese, insimbi engavimbeli i-cavitation, insimbi engagugi, kanye nensimbi ekhethekile engagugi. Amanye ama-alloy steels ajwayelekile njengensimbi engagqwali, i-bearing steel, insimbi yensimbi ye-alloy kanye nensimbi yesakhiwo sengxubevange nazo zisetshenziswa njengensimbi engagugi ngaphansi kwezimo ezithile.

Izinsimbi ezikwazi ukumelana nokuqina kwe-alloy emaphakathi nephansi ngokuvamile ziqukethe izakhi zamakhemikhali ezifana ne-silicon, i-manganese, i-chromium, i-molybdenum, i-vanadium, i-tungsten, i-nickel, i-titanium, i-boron, ithusi, umhlaba ongavamile, njll. Amalayini amabhola amaningi amakhulu naphakathi nendawo Izigayo e-United States zenziwe nge-chromium-molybdenum-silico-manganese noma insimbi ye-chromium-molybdenum. Iningi lamabhola okugaya e-United States enziwe ngensimbi ye-carbon chromium molybdenum ephakathi nendawo nephezulu. Okwezingcezu zokusebenza ezisebenza ngaphansi kwezinga lokushisa eliphakeme kakhulu (isibonelo, 200~500℃) izimo zokuguga ezilumayo noma izindawo zazo ezingaphansi kwamazinga okushisa aphakeme kakhulu ngenxa yokushisa okungqubuzanayo, ama-alloys afana ne-chromium molybdenum vanadium, chromium molybdenum vanadium nickel noma i-chromium vanadium molybde ingasetshenziswa.

I-abrasion isenzeko lapho okubalulekile endaweni yokusebenza yento konakala ngokuqhubekayo noma kulahleke ukunyakaza okuhlobene. Ihlukaniswe ngendlela yokuguga, okugqokwayo kungahlukaniswa kube ukuguguleka, ukunamathela okunamathelayo, ukugqwala kokugqwala, ukuguguleka kokuguguleka, ukuguga kokuthintana, ukuguga komthelela, ukugqokwa kwe-fretting nezinye izigaba. Emkhakheni wezimboni, i-abrasive wear ne-adhesive wear wear i-akhawunti yengxenye enkulu yokwehluleka ukugqokwa kwezingcezu zokusebenza, nezindlela zokwehluleka ukugqokwa njengokuguguleka, ukugqwala, ukukhathala, kanye nokukhathazeka kuvame ukwenzeka ekusebenzeni kwezinye izingxenye ezibalulekile, ngakho zithola okwengeziwe. nokunakwa okwengeziwe. Ngaphansi kwezimo zokusebenza, izinhlobo eziningana zokugqoka zivame ukuvela ngesikhathi esisodwa noma ngokulandelana, futhi ukusebenzisana kokwehluleka kokugqoka kuthatha ifomu eliyinkimbinkimbi. Ukunquma uhlobo lokwehluleka kokugqoka kwe-workpiece kuyisisekelo sokukhetha okunengqondo noma ukuthuthukiswa kwensimbi engagugi.

Ngaphezu kwalokho, ukuguga kwezingxenye nezingxenye kuyinkinga yobunjiniyela besistimu. Kunezici eziningi ezithinta ukuguga, okuhlanganisa izimo zokusebenza (umthwalo, isivinini, imodi yokunyakaza), izimo zokuthambisa, izici zemvelo (umswakama, izinga lokushisa, imidiya ezungezile, njll.), nezici zempahla ( Ukwakheka, inhlangano, izakhiwo zemishini), indawo engaphezulu izinga kanye nezakhiwo zomzimba kanye namakhemikhali ezingxenye. Izinguquko kunto ngayinye yalezi zici zingashintsha inani lokuguga futhi zishintshe ngisho nendlela yokugqokwa. Kungabonakala ukuthi isici sezinto ezibonakalayo singenye yezinto ezithinta ukugqokwa kwe-workpiece. Ukuze uthuthukise ukumelana nokugqoka kwezingxenye zensimbi, kuyadingeka ukuthi uqale ngesistimu yokungqubuzana nokugqoka jikelele ngaphansi kwezimo ezithile ukuze kuzuzwe umphumela oyifunayo.

1. Ukwelashwa Kokushisa Kwesixazululo (Ukwelashwa Okuqinisa Amanzi) Kwensimbi Engazweli Ngensimbi Ephakeme YeManganese

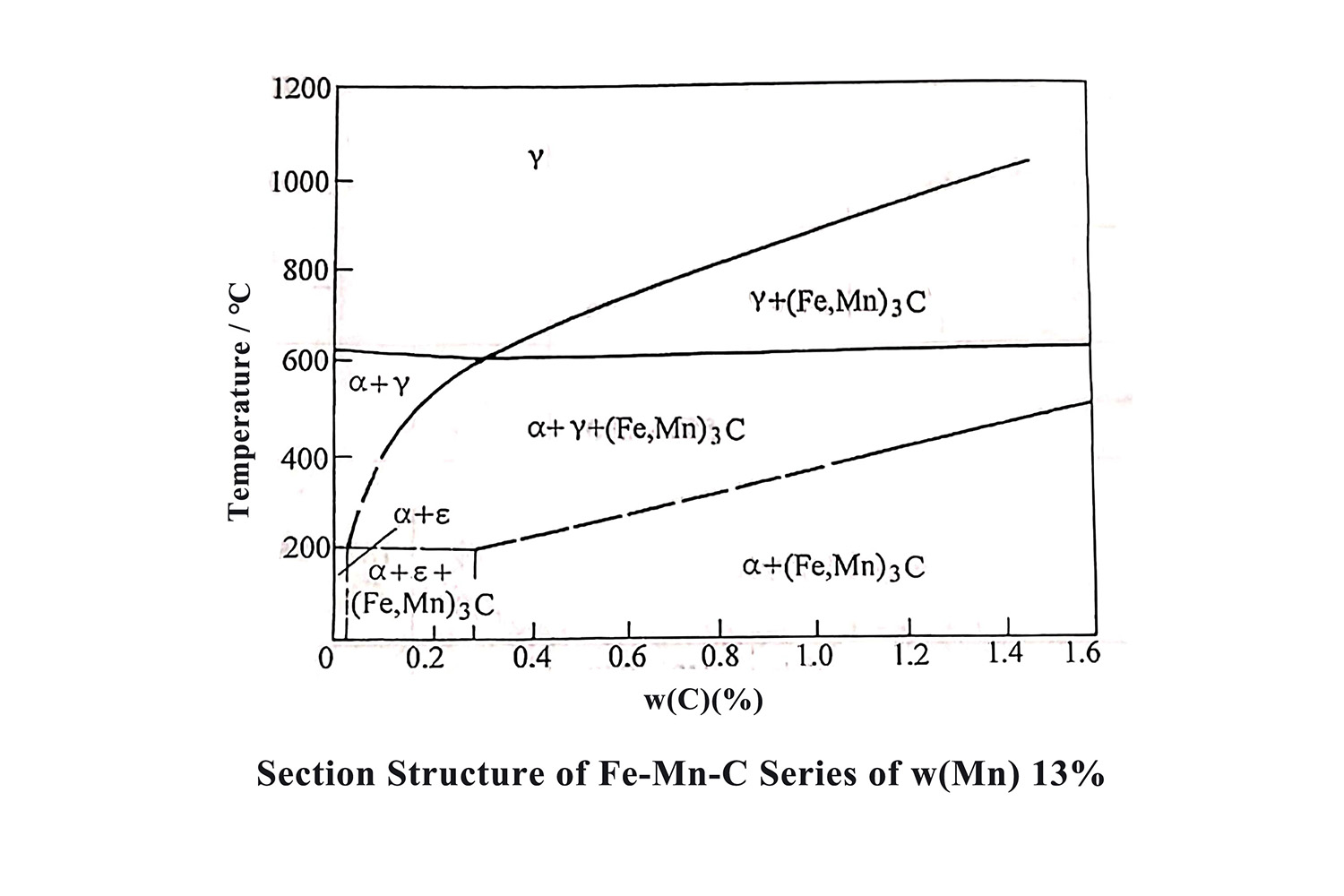

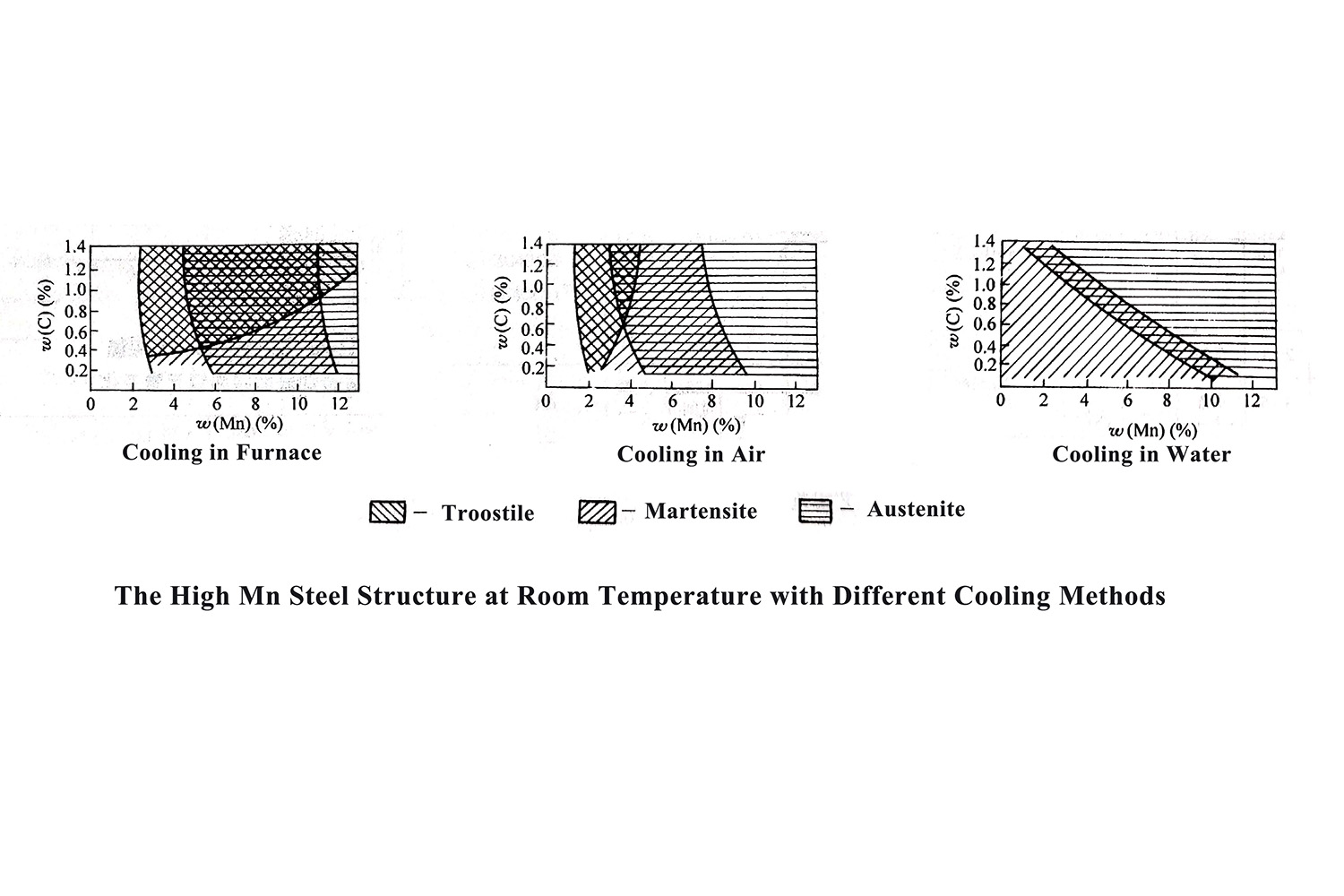

Kunenani elikhulu lama-carbide anciphile esakhiweni esisansimbi sensimbi engagugiyo ye-high-manganese. Lawa ma-carbides azonciphisa ukuqina kokusakazwa futhi enze kube lula ukuphuka ngesikhathi sokusetshenziswa. Inhloso eyinhloko yokwelashwa kokushisa kwesisombululo sensimbi ephezulu ye-manganese ukukhipha ama-carbides esakhiweni se-as-cast kanye nemingcele yokusanhlamvu ukuze kutholwe isakhiwo se-austenite sesigaba esisodwa. Lokhu kungathuthukisa amandla kanye nokuqina kwensimbi ephezulu ye-manganese, ukuze ukukhishwa kwensimbi ephezulu ye-manganese kulungele uhla olubanzi lwezinkambu.

Isixazululo sokwelashwa kokushisa kokumelana nokuqina kwensimbi ephezulu ye-manganese kungahlukaniswa ngezinyathelo ezimbalwa: ukushisa ama-castings abe ngaphezu kuka-1040 ° C futhi uwabambe isikhathi esifanele, ukuze ama-carbides akuwo ancibilike ngokuphelele ku-single-phase austenite. ; ke ukupholisa ngokushesha , Thola austenite esiqinile isisombululo isakhiwo. Lokhu kwelashwa kwesixazululo kubizwa nangokuthi ukwelashwa kokuqinisa amanzi.

(1) Izinga lokushisa lokwelapha okuqinisa amanzi

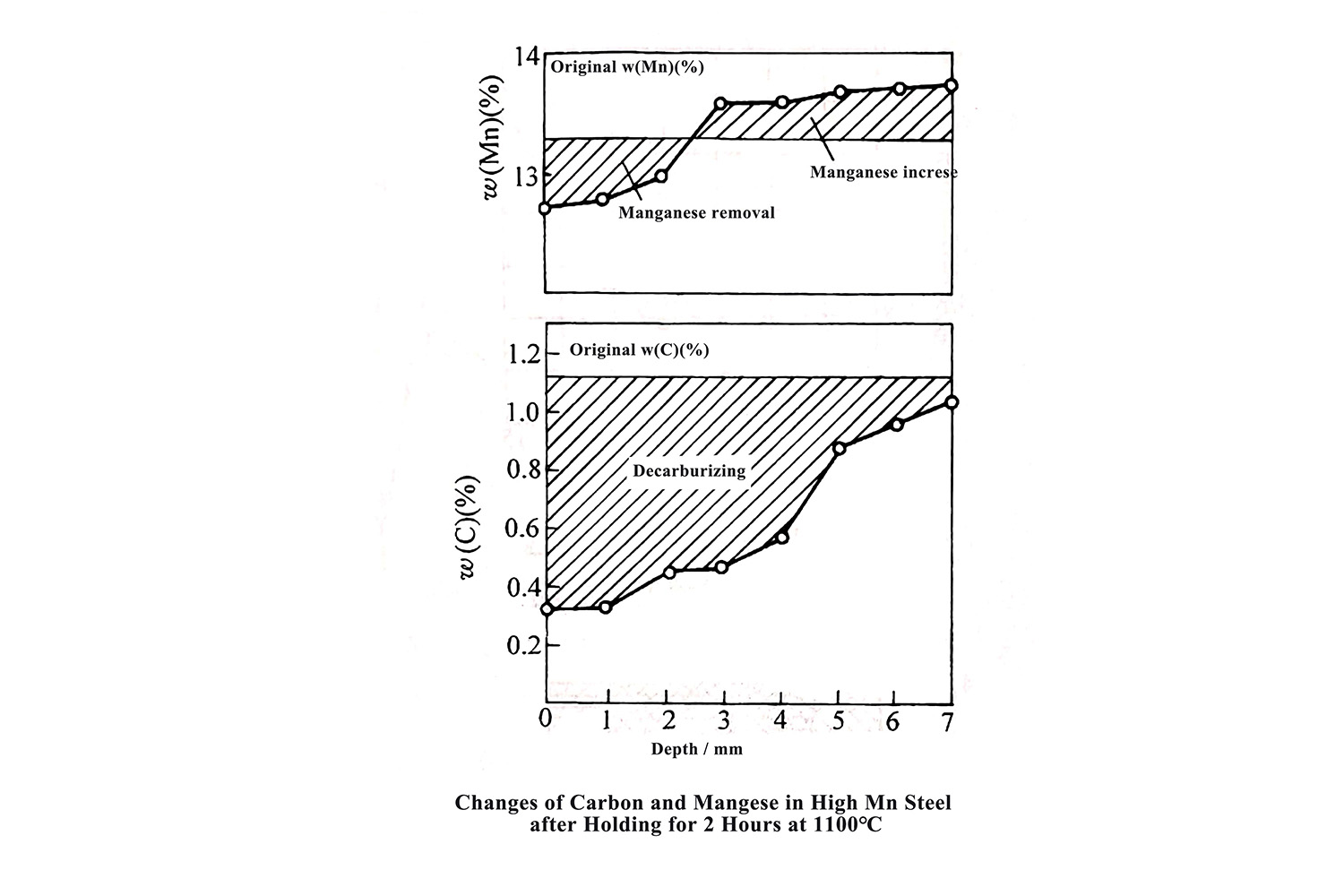

Izinga lokushisa lokuqina kwamanzi lincike ekwakhekeni kwamakhemikhali ensimbi ephezulu ye-manganese, imvamisa engu-1050℃-1100℃. Izinsimbi ze-manganese eziphezulu ezinokuqukethwe kwekhabhoni ephezulu noma okuqukethwe kwe-alloy ephezulu (njengensimbi ye-ZG120Mn13Cr2 kanye nensimbi ye-ZG120Mn17) kufanele kuthathe umkhawulo ophezulu wezinga lokushisa lokuqina kwamanzi. Kodwa-ke, izinga lokushisa eliphakeme kakhulu lokuqina kwamanzi lizodala ukuwohloka okukhulu kwe-carbur ebusweni bokubunjwa kanye nokukhula okusheshayo kwezinhlamvu zensimbi ze-manganese, okuzophazamisa ukusebenza kwensimbi ephezulu ye-manganese.

(2) Izinga lokushisa lokwelapha okuqinisa amanzi

I-thermal conductivity yensimbi ye-manganese yimbi kakhulu kune-carbon steel evamile. Izinsimbi ze-high-manganese zinengcindezi ephezulu futhi kulula ukuqhekeka uma kushisa, ngakho-ke izinga lokushisa kufanele linqunywe ngokuya ngokuqina kodonga kanye nokuma kokubunjwa. Ngokuvamile, ukulingisa okunobukhulu obuncane bodonga kanye nesakhiwo esilula kungashiswa ngesivinini esisheshayo; ama-castings anobukhulu obukhulu bodonga kanye nesakhiwo esiyinkimbinkimbi kufanele ashiswe kancane. Enqubweni yangempela yokwelashwa kokushisa, ukuze kuncishiswe ukuwohloka noma ukuqhekeka kokusakazwa ngesikhathi senqubo yokushisisa, kuvamise ukushisisa kuze kufike ku-650 ℃ ukuze kugcinwe umehluko wezinga lokushisa phakathi kwangaphakathi nangaphandle kokuphonswa kwehliswe, kanye nezinga lokushisa ngaphakathi. isithando somlilo siyiyunifomu, bese sikhuphuka ngokushesha ekushiseni kokuqina kwamanzi.

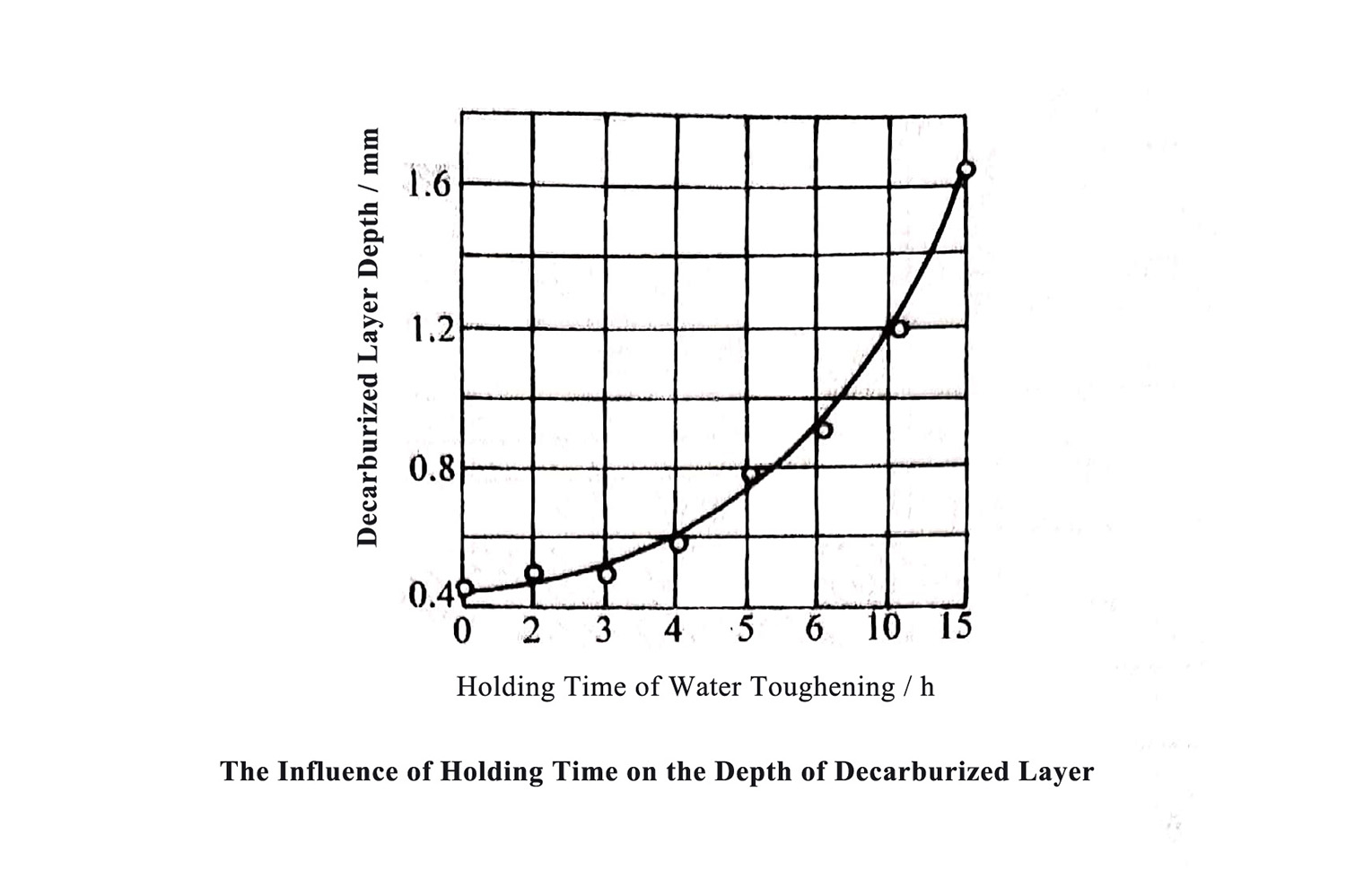

(3) Ukubamba isikhathi sokwelashwa kokuqina kwamanzi

Isikhathi sokubamba sokwelashwa okuqinisa amanzi ngokuyinhloko sincike ekugqineni kodonga lokukhishwa, ukuze kuqinisekiswe ukuqedwa okuphelele kwama-carbides esakhiweni se-as-cast kanye ne-homogenization yesakhiwo se-austenite. Ngaphansi kwezimo ezijwayelekile, ingabalwa ngokukhuphula isikhathi sokubamba ngehora elingu-1 kukho konke ukwanda okungama-25 mm odongeni.

(4) Ukupholisa ukwelashwa kokuqina kwamanzi

Inqubo yokupholisa inethonya elikhulu kunkomba yokusebenza kanye nesakhiwo sokulingisa. Ngesikhathi sokwelashwa kokuqina kwamanzi, izinga lokushisa lokuphonsa ngaphambi kokungena emanzini kufanele libe ngaphezu kuka-950 ° C ukuvimbela ama-carbides ukuthi angaphinde abe nemvula. Ngalesi sizathu, isikhawu sesikhathi phakathi kokukhipha isithando somlilo nokungena emanzini akufanele sidlule imizuzwana engama-30. Ukushisa kwamanzi kufanele kube ngaphansi kuka-30 ° C ngaphambi kokuba ukubunjwa kungene emanzini, futhi izinga lokushisa eliphezulu lamanzi ngemva kokungena emanzini akufanele lidlule ku-50 ° C.

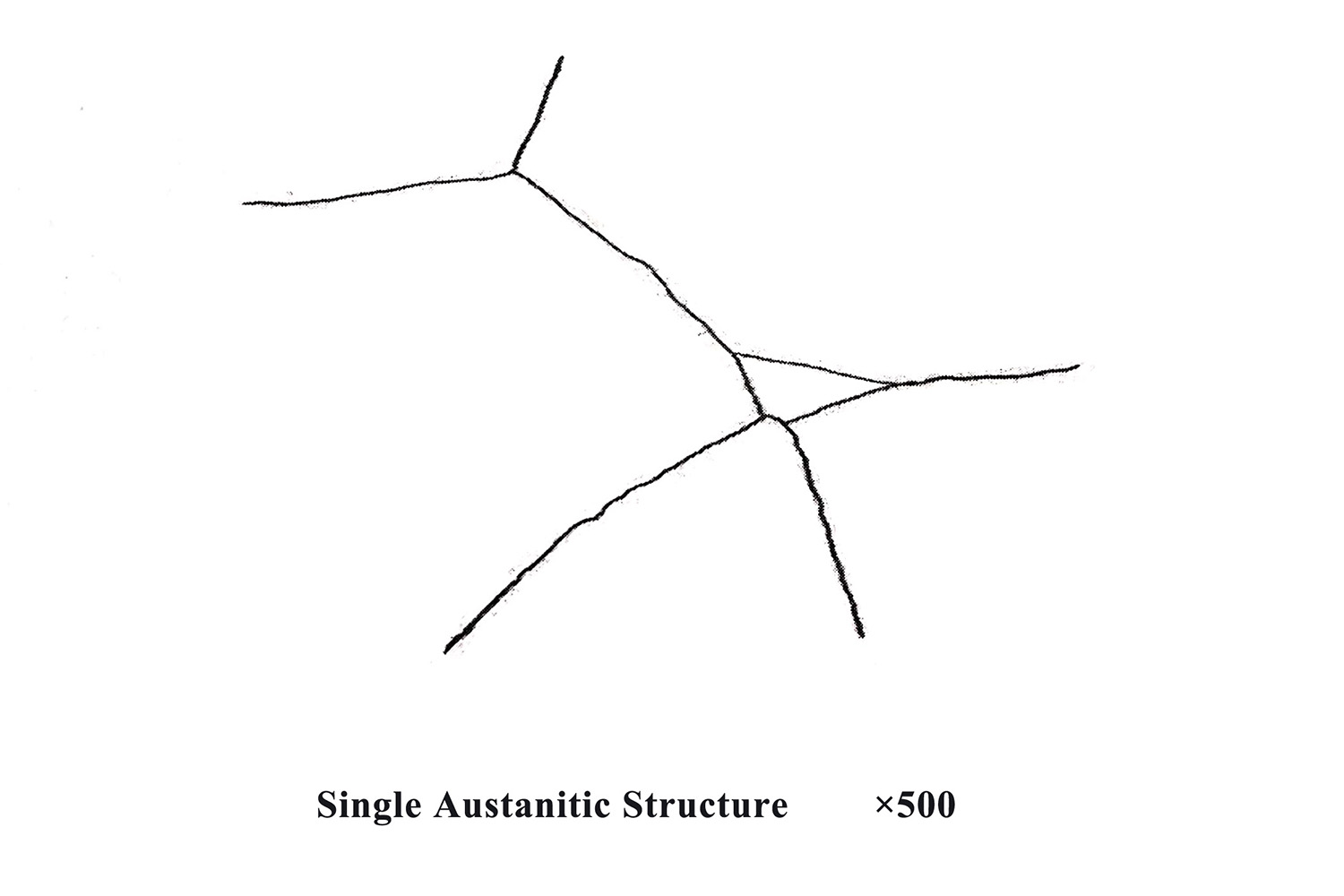

(5) Carbide ngemva kokwelashwa amanzi toughening

Ngemuva kokwelashwa kokuqina kwamanzi, uma ama-carbides ensimbi ephezulu ye-manganese eqedwa ngokuphelele, isakhiwo se-metallographic esitholakala ngalesi sikhathi siyisakhiwo esisodwa se-austenite. Kodwa isakhiwo esinjalo singatholakala kuphela kuma-castings anezindonga ezincane. Ngokuvamile, inani elincane le-carbides kuzinhlamvu ze-austenite noma emingceleni yokusanhlamvu kuvunyelwe. Ama-carbides angancibilikisiwe kanye nama-carbide anciphile angaqedwa ngokwelashwa okushisa futhi. Kodwa-ke, ama-eutectic carbides akhuphuka ngenxa yokushisa okushisayo ngesikhathi sokwelashwa okuqinisa amanzi awamukeleki. Ngoba i-eutectic carbide ayikwazi ukuqedwa ngokwelashwa okushisa futhi.

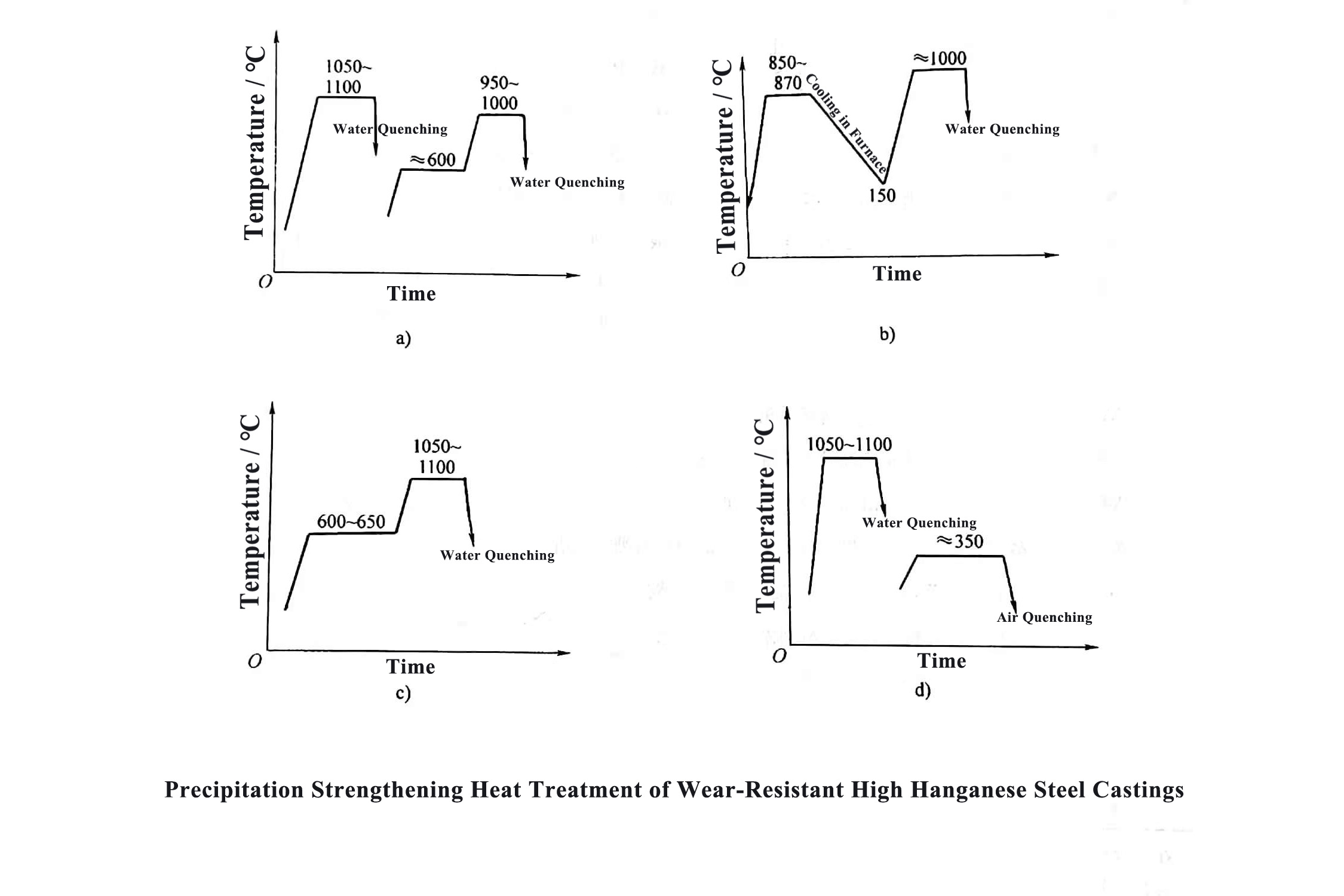

2. Imvula Iqinisa Ukwelashwa Kokushisa Kwezinsimbi Eziqinile ze-Hanganese Ezingazweli

Ukwelashwa kokushisa okuqinisa imvula kwensimbi ephezulu ye-manganese engagugi kubhekisela ekwengezweni kwenani elithile lezinto zokwakha i-carbide (njenge-molybdenum, i-tungsten, i-vanadium, i-titanium, i-niobium ne-chromium) ngokwelashwa kokushisa ukuze kutholwe inani elithile nosayizi high manganese steel Isigaba sesibili sezinhlayiya ze-carbide ezihlakazekile. Lokhu kwelashwa kokushisa kungaqinisa i-matrix ye-austenite futhi kuthuthukise ukumelana nokugqokwa kwensimbi ephezulu ye-manganese.

3. Ukwelashwa Kokushisa Kokusakaza Kwensimbi Ye-Chromium Engaguquki

Inhloso yokwelashwa kokushisa kwezinsimbi ze-chromium ekwazi ukumelana nokugqoka ukuthola ukwakheka kwe-matrix ye-martensite enamandla amakhulu, ukuqina kanye nokuqina okuphezulu, ukuze kuthuthukiswe amandla, ukuqina nokumelana nokugqokwa kwezinsimbi zensimbi.

Insimbi ye-chromium ephakathi nendawo engagqoki iqukethe izinto eziningi ze-chromium futhi inokuqina okuphezulu. Ngakho-ke, indlela yayo evamile yokwelapha ukushisa ithi: ngemva kuka-950 ℃-1000℃, i-austenitization yayo, bese icisha ukwelashwa, kanye nokwelashwa okufika ngesikhathi (imvamisa ku-200-300 ℃).

4. Ukwelashwa Kokushisa Kwensimbi Engavimbeli I-Wear-Alloy Low-Alloy Castings

Insimbi engagqoki enengxubevange ephansi iphathwa ngokucisha emanzini, ukucisha emafutheni nasekucimeni komoya kuye ngokwakheka kwengxubevange nokuqukethwe kwekhabhoni. I-Pearlitic wear-resistant cast steel yamukela ukwelashwa okujwayelekile okujwayelekile + okufudumeza ukushisa.

Ukuze uthole i-matrix ye-martensite enamandla amakhulu, ukuqina nobulukhuni, kanye nokuthuthukisa ukumelana nokugqokwa kwezinsimbi zensimbi, ukukhishwa kwensimbi okungagugiyo okuqinile kwe-alloy ngokuvamile kucishwa ku-850-950 ° C futhi kushiswe ku-200-300 ° C. .

Isikhathi sokuthumela: Aug-07-2021