Kokubili i-iron empunga ne-ductile iron kungaphonswa ngakhoinqubo yokuphonsa isihlabathi, inqubo yokubumba igobolondo (isihlabathi esimbozwe inhlaka), ukukhishwa kwegwebu elilahlekile, ukukhishwa kwe-vacuum nokufaka utshalomali. Ukulingisa isihlabathi kungenye yezinhlobo ezidume kakhulu nezilula zokulingisa. Ukufakwa kwesihlabathi kuvumela amaqoqo amancane kunokubunjwa kwesikhunta unomphela futhi ngezindleko ezizwakalayo. Le ndlela ayigcini nje ngokuvumela abakhiqizi ukuthi benze imikhiqizo ngenani eliphansi, kodwa kunezinye izinzuzo zokuphonsa isihlabathi, njengokusebenza kosayizi omncane kakhulu. Ukubunjwa kwesihlabathi nakho kuvumela izinsimbi eziningi ukuthi ziphonswe, kuye ngokuthi hlobo luni lwesihlabathi esisetshenziselwa isikhunta. Inqubo yokubunjwa kwegobolondo ibizwa nangokuthi inqubo yokuphonsa isihlabathi se-resin ehlanganiswe ngaphambili, ukubunjwa kwegobolondo elishisayo noma inqubo yokuphonsa okuyisisekelo. Impahla yokubumba eyinhloko isihlabathi se-phenolic resin esakhiwe ngaphambili, esibiza kakhulu kunesihlabathi esiluhlaza nesihlabathi se-furan resin. Ngaphezu kwalokho, lesi sihlabathi asikwazi ukuphinda sisetshenziswe. Izingxenye zokuphonswa kwensimbi yegobolondo zinezindleko eziphakeme kunokubunjwa kwesihlabathi. Nokho, iizingxenye zokubunjwa kwegobolondozinezinzuzo eziningi ezifana nokubekezelelana okuqinile, ikhwalithi enhle yangaphezulu kanye nokukhubazeka okuncane kokulingisa.

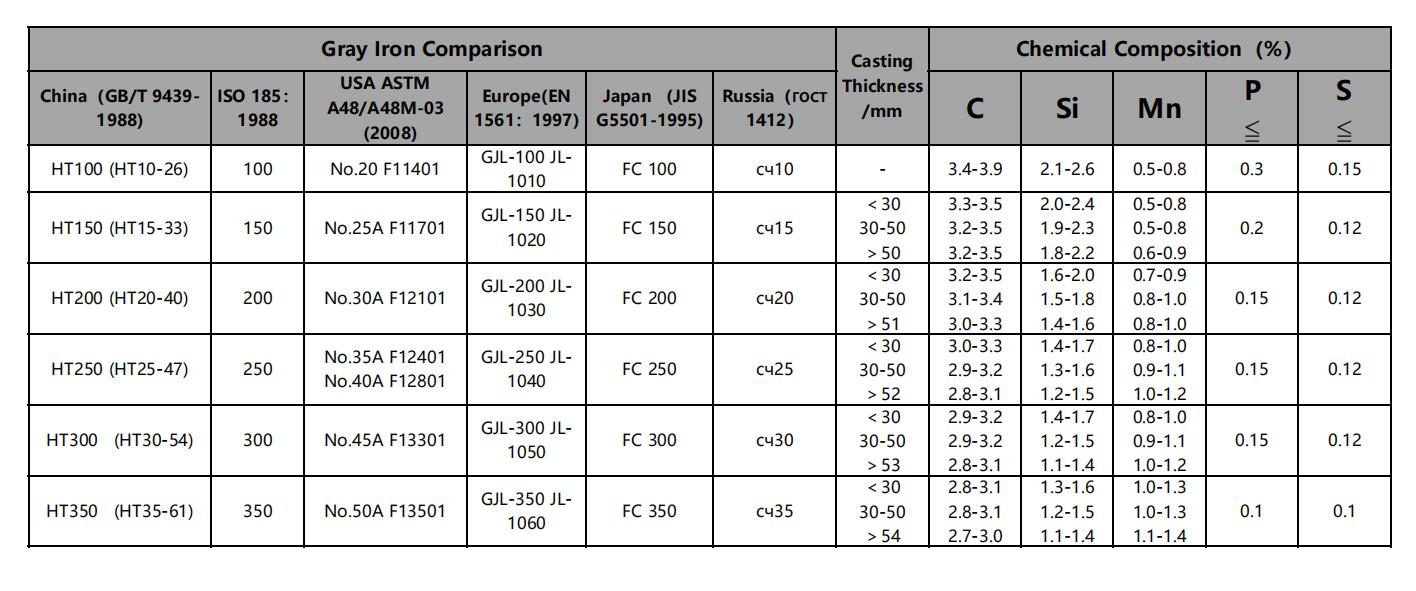

Kodwa-ke, kusenomehluko phakathi kwezingxenye zensimbi ezimpunga kanye nezingxenye zokuphonsa i-ductile iron.I-Grey Iron Sand Castingivame ukusetshenziselwa ukwenza izimo eziyinkimbinkimbi okungenzeka kube nzima noma ezingenayo imali ukuzenza ngezinye izinqubo zokwenza insimbi. Ngenxa yobulula bayo bemishini, amandla aphezulu okucindezela, ukuguquguquka okungcono kokushisa kanye nokumuncwa kokudlidliza okuhle kakhulu, insimbi empunga ingenye yensimbi yokuphonsa esetshenziswa kakhulu isikhathi eside kakhulu, ngisho nasekukhiqizweni kwemboni yamanje. Okuqukethwe kwekhabhoni kuyisici esibaluleke kakhulu se-iron empunga (imvamisa engu-2% ukuya ku-4%) ukuze kwakheke amandla aqinile kanye nokusebenza kanzima. Lapho insimbi encibilikisiwe iqinisa amanye ama-carbon precipitate njenge-graphite, yenze ama-flakes amancane, angajwayelekile ngaphakathi kwesakhiwo sekristalu sensimbi esithuthukisa izici ezifiselekayo zensimbi ewugqinsi, ama-flakes aphazamisa ukwakheka kwekristalu okuholela ekuhlakazekeni kwesici se-cast iron.

Ukuthuthukiswa kwe-grey cast iron ikakhulukazi kuqhutshwa amandla aphezulu. Esikhathini esidlule, indlela eyinhloko yokuthuthukisa ukusebenza kwe-grey cast iron kwakuyi-inoculation. Eminyakeni yamuva nje, indlela eyinhloko manje iwukugxila ekuhlanganiseni ingxubevange, futhi ukuze kuthuthukiswe ukusebenza kokusakazwa, izimboni eziningi zensimbi ezimpunga zisebenzisa insimbi ekhonjiwe enokulingana kwekhabhoni ephezulu. Lokhu kubaluleke kakhulu ku-low alloy cast iron. Ngakho-ke, i-grey cast iron iyimpahla efanelekile yokukhiqiza izingxenye zensimbi ze-injini block, izindlu zemishini, isisekelo somshini, izisindo zokubala, izingxenye zesitofu, izingxenye zebhayela, amagobolondo epompo nokunye.

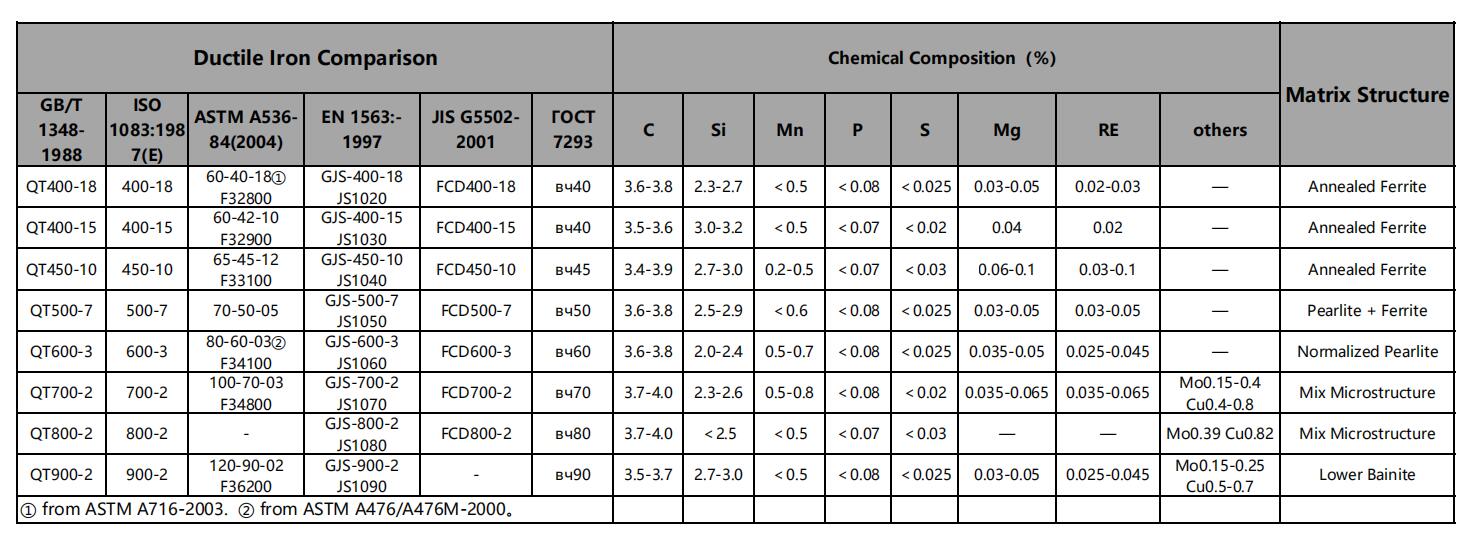

I-Ductile iron inikeza ukuguquguquka kokuklama kanye nezindleko ezincishisiwe zokukhiqiza uma kuqhathaniswa nokwakhiwa okushiselwe kanye nama-forging. Ku-microstructure ye-ductile iron, i-graphite yenza ama-nodule ayindilinga esikhundleni sama-flakes, ngaleyo ndlela ivimbele ukwakhiwa kwemifantu futhi inikeze i-ductility ethuthukisiwe enikeza i-alloy igama layo. I-iron Ductile inamandla aphezulu okuqina kanye nokuqina okufana nensimbi.I-Ductile iron castingszinezici eziningi, nokho, azihlali ziyindlela ebiza kakhulu kunezinye izingxube zensimbi. Ukwengeza, izinsimbi ze-ductile zisetshenziswa kabanzi ezimbonini eziningi zokukhiqiza, okuhlanganisa ezolimo, izimoto, ezokuthutha amanzi, izitimela zesitimela, amaloli ezentengiselwano kanye nezimboni ze-aerospace.

Isikhathi sokuthumela: Jan-27-2021