Insimbi engagqwali ye-Ferritic isho insimbi engagqwali ene-cubic ferrite egxile emzimbeni njengesakhiwo se-matrix ezingeni lokushisa eliphezulu kanye nezinga lokushisa elivamile. Insimbi engagqwali ye-Ferritic ine-ayoni ne-chromium njengezici eziyinhloko, ngokuvamile ayinayo i-nickel, futhi enye iqukethe inani elincane le-molybdenum, i-titanium noma i-niobium nezinye izakhi. Inokumelana okuhle ne-oxidation, ukumelana nokugqwala kanye nokumelana nokuqhekeka kwe-chloride. Ngaphezu kwalokho, insimbi engagqwali ye-ferritic nayo inezici ze-conductivity enkulu yokushisa, i-coefficient encane yokwandisa, ukumelana okuhle kwe-oxidation, nokumelana okuhle kakhulu nokugqwala kwengcindezi. Isetshenziswa kakhulu ukwenza izingxenye ezimelana nomkhathi, umhwamuko wamanzi, amanzi, kanye nokugqwala kwe-oxidative acid. Abamele amamaki ensimbi engagqwali ye-ferritic yilawa: AISI 410 (UNS S41000), AISI 420 (UNS S42000), AISI 430 (UNS S43000) ngokusho kwe-ASTM; 1.4006, 1.4021, 1.4016, ngokuya nge-EN standard...njll.

Insimbi engagqwali ye-Ferritic ingahlukaniswa ibe yi-chromium ephansi, i-chromium emaphakathi ne-chromium ephezulu ngokuya ngokuqukethwe kwe-chromium. Ngokuvumelana nokuhlanzeka kwensimbi, ikakhulukazi okuqukethwe ukungcola kwekhabhoni ne-nitrogen, ingahlukaniswa ibe insimbi engagqwali evamile ye-ferritic kanye ne-ultra-pure ferritic stainless steel. Insimbi engagqwali evamile ye-ferritic inokungalungi kwezinga lokushisa eliphansi kanye nokuqina kwezinga lokushisa kwegumbi, ukuzwela kwenotshi, ukuthambekela kokugqwala okuphezulu kwe-intergranular, kanye nokushisela okubi. Nakuba lolu hlobo lwensimbi lwathuthukiswa ngaphambili, ukusetshenziswa kwalo kwezimboni kuvinjelwe kakhulu. Lokhu kushoda kwensimbi engagqwali evamile ye-ferritic kuhlobene nokuhlanzeka kwensimbi, ikakhulukazi okuqukethwe okuphezulu kwezakhi ze-interstitial ezifana nekhabhoni ne-nitrogen ensimbi. Uma nje ikhabhoni ne-nitrogen esensimbini iphansi ngokwanele, lokhu kushiyeka okungenhla kunganqotshwa.

Uma kuqhathaniswa neinsimbi engagqwali ye-austenitic, insimbi engagqwali ye-ferritic inokumelana nokugqwala okungcono, ukumelana nokushisa nokusebenza kahle. Njengoba isigaba se-ferrite singakwazi ukuncibilikisa ikhabhoni, i-ferrite inezici zokuthamba futhi kulula ukuyikhubaza. Njengensimbi engagqwali ye-martensitic, njengoba isakhiwo se-lattice siyisakhiwo se-cubic esigxile emzimbeni, singama-paramagnetic, ngakho insimbi engagqwali ye-ferritic inozibuthe. Insimbi engagqwali ye-Austenitic ayiyona i-magnetic ngenxa yesakhiwo sayo se-cubic esigxile ebusweni.

Intengo yensimbi engagqwali ye-ferritic ayigcini nje ngokuphansi futhi izinzile, kodwa futhi inezici eziningi eziyingqayizivele kanye nezinzuzo. Kufakazelwe ukuthi insimbi engagqwali ye-ferritic ingenye yezinto ezinhle kakhulu.

Insimbi engagqwali evamile ye-ferritic

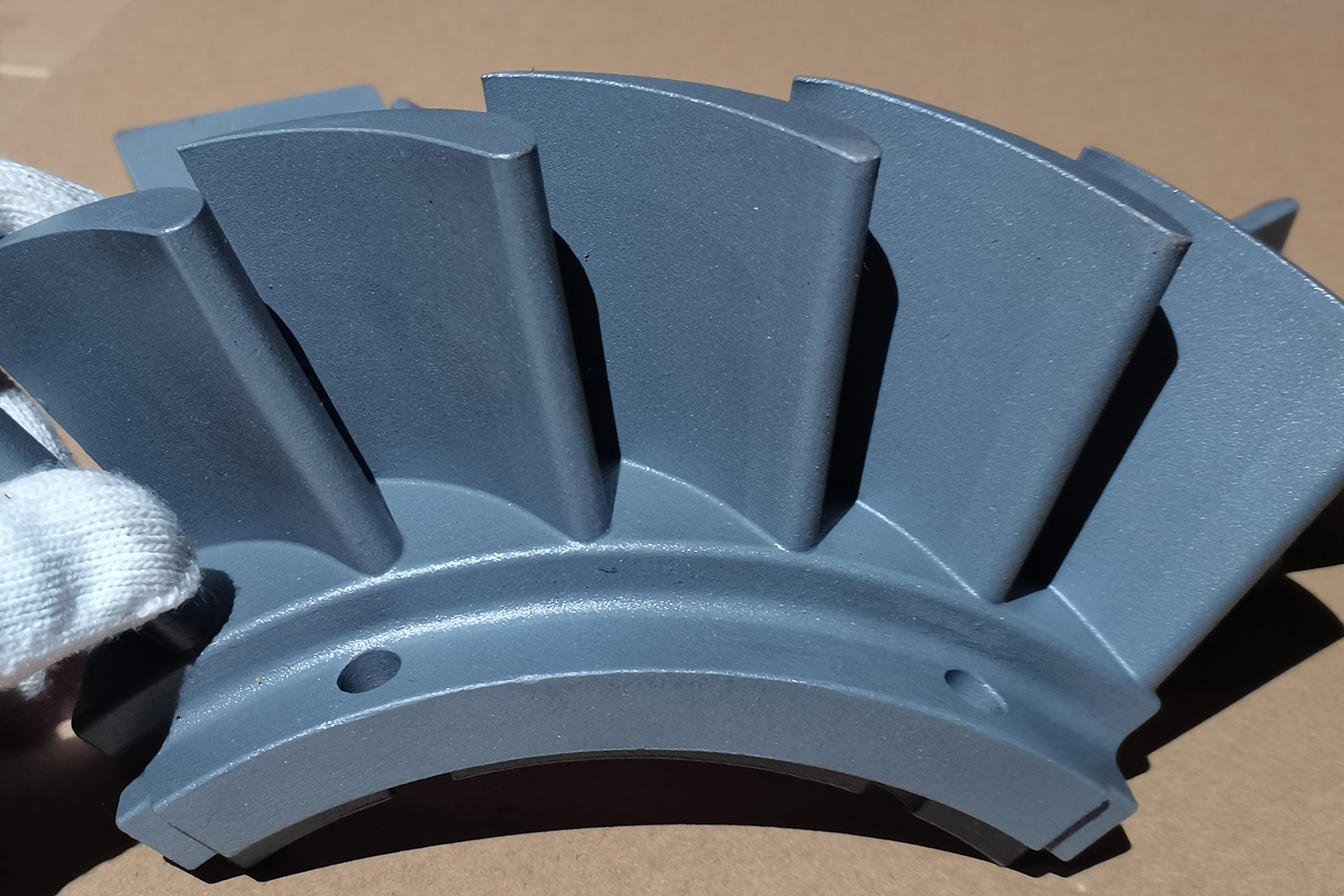

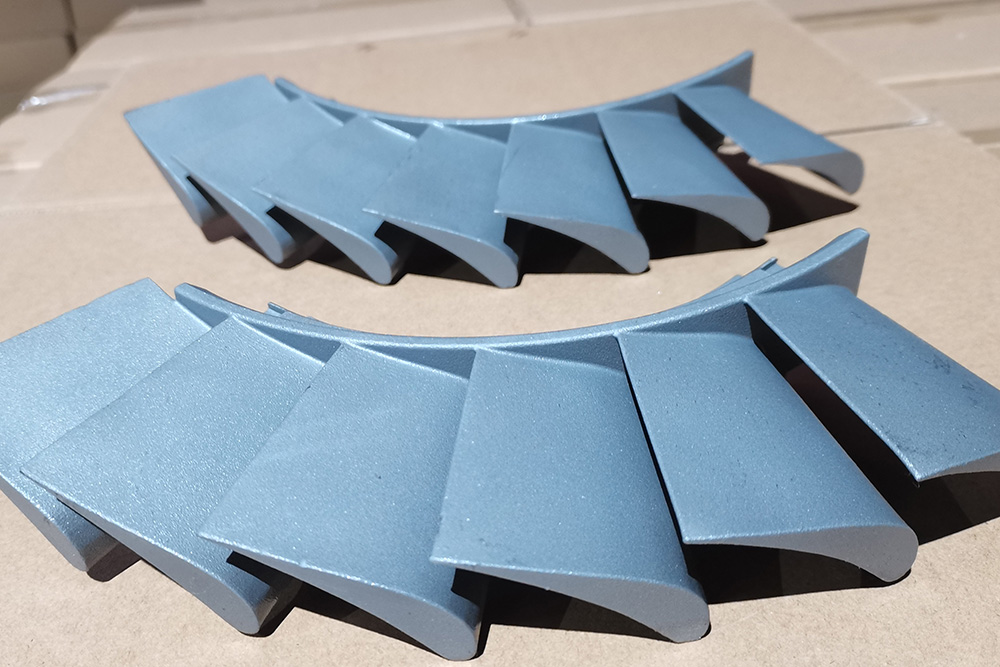

Izinsimbi ezinjalo zihlanganisa okuqukethwe kwe-chromium ephansi, ephakathi nendawo ephezulu. Insimbi engagqwali ephansi ye-chromium ferritic iqukethe cishe u-11% kuya ku-14% we-chromium, efana ne-00Cr12 ne-0Cr13Al e-China. American AISI 400, 405, 406MF-2. Lolu hlobo lwensimbi lunokuqina okuhle, ipulasitiki, i-deformation ebandayo kanye nokushisela. Ngenxa yokuthi insimbi iqukethe inani elithile le-chromium ne-aluminium, inokumelana okuhle ne-oxidation nokumelana nokugqwala. I-405 ingasetshenziswa njengombhoshongo wokuhluza uphethiloli, ulayini wethangi, i-steam turbine blade, idivayisi ekwazi ukumelana nokugqwala kwesibabule, njll. 400 kumishini yasendlini neyasehhovisi, njll. njll. Insimbi engagqwali ye-chromium ferritic emaphakathi, okuqukethwe kwe-chromium kungu-14% 19%, njenge-1Cr17 ne-1Cr17Mo e-China. AISI 429, AISI 430, AISI 433, AISI 434, AISI 435, AISI 436, AISI 439 e-United States. Lolu hlobo lwensimbi lunokugqwala okungcono nokumelana nokugqwala. I-coefficient yayo yokuqinisa umsebenzi incane (n≈2), futhi inomdwebo omuhle wokusebenza ojulile, kodwa i-ductility yayo ayilungile. I-AISI 430 insimbi engagqwali ye-ferritic isetshenziselwa umhlobiso wezakhiwo, umhlobiso wezimoto, imishini yekhishi, izishisi zegesi kanye nezingxenye zemishini yezimboni ze-nitric acid, njll. I-AISI 434 isetshenziselwa ukuhlobisa kwangaphandle kwezimoto nezakhiwo. I-439 isetshenziswa njengepayipi lokushisisa amanzi egesi, amapayipi amalahle nawegesi, njll. Insimbi engagqwali ephezulu ye-chromium ferritic iqukethe u-19% kuya ku-30% we-chromium, njenge-Cr18Si2 ne-Cr25 e-China, i-AISI 442, i-AISI 443 ne-AISI 446 e-United. Amazwe. Izinsimbi ezinjalo zinokumelana okuhle kwe-oxidation. I-AISI 442 isetshenziswa ngokuqhubekayo emkhathini, izinga lokushisa eliphezulu elilinganiselwe lingu-1035°C, kanti izinga lokushisa eliphezulu lokusebenzisa ngokuqhubekayo lingu-980°C. I-AISI 446 insimbi engagqwali ye-ferritic inokumelana okungcono ne-oxidation.

I-high-purity ferritic stainless steel

Lolu hlobo lwensimbi luqukethe ikhabhoni ephansi kakhulu, initrogen; i-chromium ephezulu, i-molybdenum, i-titanium, i-niobium nezinye izakhi. Njenge-00Cr17Mo yaseChina, 00Cr18Mo2, 00Cr26Mol, 00Cr30Mo2. Lolu hlobo lwensimbi lunezinto ezinhle zomshini (ikakhulukazi ukuqina), ukushisela, ukumelana nokugqwala kwe-intergranular, ukumelana nokugqwala kwe-pitting, ukumelana nokugqwala kwe-crevice, kanye nokumelana okuhle kakhulu nokuqhekeka kokugqwala. Isibonelo, insimbi engagqwali engu-18-2 ferritic inokumelana nokugqwala okuhle ku-nitric acid, i-acetic acid, i-NaOH, ukumelana nokugqwala kwe-pitting ku-3% NaCl kanye ne-FeCl3 kulingana noma yedlula i-18-8 austenitic stainless steel, insimbi engu-26CrMo emithonjeni eminingi yokumelana nokubola. , ikakhulukazi kuma-organic acid, ama-oxidizing acid, nama-alkali aqinile. Inokumelana nokugqwala okuhle kwe-pitting endaweni eqinile ye-chloride. Akukho ukuqhekeka kokugqwala kwengcindezi okwenzeka ku-chloride, i-hydrogen sulfide, i-sulfuric acid eningi kanye ne-alkali enamandla. I-30Cr-2Mo inokumelana okuphezulu nokugqwala komgodi kanye nokugqwala kokuqhekeka ngenkathi igcina ukumelana nokugqwala kwengcindezi.

Ukumelana nokugqwala kwensimbi engagqwali ye-ferritic

(1) Ukugqwala okufanayo.

I-Chromium iyisici esilula kakhulu ukuthi singayidlulisi. Endaweni yomoya, ingxubevange ye-iron-chromium enokuqukethwe kwe-chromium engaphezu kuka-12% ingakwazi ukuzihambela. Endaweni ene-oxidizing, okuqukethwe kwe-chromium kungadluliswa uma kungaphezu kuka-17%. Kwenye indawo ecekela phansi, i-chromium ephezulu ne-molybdenum, i-nickel, ithusi nezinye izakhi zingangezwa ukuze kutholwe ukumelana nokugqwala okuhle.

(2) Ukugqwala kwe-intergranular.

Izinsimbi ezingenasici ze-Ferritic, njengezinsimbi ezingenasici ze-austenitic, zihlushwa ukugqwala kwe-intergranular, kodwa ukwelashwa kokuzwela nokwelashwa kokushisa ukuze kugwenywe lokhu kugqwala kuphambene. Insimbi engagqwali ye-Ferritic ijwayele ukugqwala phakathi kwe-intergranular kusukela ekupholiseni okusheshayo ngaphezu kuka-925 ° C, futhi isimo (isimo esizwelayo) esithinteka kalula ekugqwaleni kwe-intergranular singaqedwa ngemva kwesikhathi esifushane sokushisa ku-650-815 ° C. Ukugqwala kwe-intergranular yensimbi ye-ferritic nakho kuwumphumela wokuncipha kwe-chromium okubangelwa imvula ye-carbide. Ngakho-ke, ukwehlisa okuqukethwe kwekhabhoni ne-nitrogen kunsimbi nokwengeza izakhi ezifana ne-titanium ne-niobium kunganciphisa ukuba sengozini kokugqwala kwe-intergranular.

(3) Ukugqwala kwemigodi nemifantu.

I-Chromium ne-molybdenum yizinto ezisebenza kahle kakhulu zokuthuthukisa ukumelana nokugqwala kwe-pitting kanye nokuqhekeka kwensimbi engagqwali. Njengoba okuqukethwe kwe-chromium kwanda, okuqukethwe kwe-chromium kufilimu ye-oxide nakho kuyanda, futhi ukuqina kwamakhemikhali efilimu kuyanda. I-Molybdenum ikhangiswa endaweni yensimbi esebenzayo ngendlela ye-MoO4, evimbela ukuchithwa kwensimbi, ikhuthaze ukuguqulwa, futhi ivimbele ukulimala kwefilimu. Ngakho-ke, i-chromium ephezulu nensimbi engagqwali ye-molybdenum ferritic inokumelana okuhle kakhulu nokugqwala nokugqwala kwemifantu.

(4) Ukumelana nokucindezeleka kokuqhekeka kokugqwala.

Ngenxa yezici zesakhiwo senhlangano, insimbi engagqwali ye-ferritic imelana nokugqwala endaweni lapho insimbi engagqwali ye-austenitic ikhiqiza ukuqhekeka kokugqwala kwengcindezi.

Izakhiwo zemishini yensimbi engagqwali ye-ferritic

Insimbi engagqwali ye-Ferritic ayikwazi ukuqiniswa ukwelashwa kokushisa ngoba akukho ukuguqulwa kwesigaba. Ngokuvamile, isetshenziswa ngemva kokuthuthwa kwamanzi ku-700-800°C. Ngenxa yobukhulu obufanayo be-athomu ye-athomu yensimbi ne-chromium, umphumela wokuqinisa isixazululo esiqinile mncane, amandla okukhiqiza namandla aqinile ensimbi engagqwali ye-ferritic ephakeme kancane kunaleyo yensimbi ephansi ye-carbon, futhi i-ductility iphansi kunaleyo ye-carbon steel ephansi. .

1) I-brittleness yegumbi lokushisa kwensimbi evamile ye-ferritic.

Insimbi engagqwali evamile ye-ferritic izwela kumanotshi, futhi izinga lokushisa elibi lingaphezu kwezinga lokushisa legumbi ngaphandle kwensimbi engenasici ye-chromium ferritic. Ukuphakama kokuqukethwe kwe-chromium, kubanda kakhulu ukubanda. Lokhu kubanda kwe-brittleness kuhlobene nezakhi ze-interstitial ezifana nekhabhoni ne-nitrogen ensimbi, futhi insimbi ye-ultra-pure ferritic inokuqukethwe kwekhabhoni ephansi kakhulu kuzakhi ze-interstitial ezifana ne-carbon ne-nitrogen, ngakho ingathola ukuqina okuhle, kanye noshintsho olubi. izinga lokushisa lingehliswa ngaphansi kwezinga lokushisa legumbi.

2) Ukushisa okuphezulu kwe-embrittlement yensimbi evamile ye-ferritic engagqwali.

Insimbi engagqwali evamile ye-ferritic ifudunyezwa ibe ngaphezu kuka-927°C bese ipholiswa ngokushesha ifinyelele izinga lokushisa elilingana negumbi, ipulasitiki nokuqina kuncipha kakhulu. Lokhu kufudumala kwezinga lokushisa eliphezulu kuhlobene nemvula esheshayo yezinhlanganisela zekhabhoni (i-nitride) emingceleni yokusanhlamvu noma ukuhlukaniswa kwezinga lokushisa elingu-427-927 °C. Ukunciphisa okuqukethwe kwekhabhoni ne-nitrogen kwensimbi (usebenzisa ubuchwepheshe be-ultra-pure) kungathuthukisa kakhulu lokhu konakala. Ngaphezu kwalokho, lapho insimbi ye-ferritic ishisa ngaphezu kuka-927 ° C, umthamo wokusanhlamvu uzoqiniswa, futhi okusanhlamvu okuqinile kuzolimaza ipulasitiki nokuqina kwensimbi.

3) Ukwakhiwa kwesigaba sika-σ.

Ngokomdwebo wesigaba se-iron-chromium, uma igcinwa ku-500-800°C, ingxubevange equkethe u-40% -50% chromium izokwakha isigaba esisodwa u-σ, futhi ingxubevange equkethe ngaphansi kuka-20% noma ngaphezulu kuka-70% chromium izokwakhiwa. isakhiwo sesigaba esikabili esingu-α+σ. Ukwakheka kwe-σ-isigaba kuzonciphisa kakhulu i-ductility nokuqina kwensimbi. Ngakho-ke, insimbi engagqwali ye-ferritic akufanele isetshenziswe isikhathi eside ku-500-800 ° C.

4) Ukuqina ku-475°C.

I-chromium ephezulu (>15%) insimbi ye-ferritic izomiswa ngokuqinile uma igcinwe ku-400-500 °C. Lolu hlobo lwe-embrittlement luthatha isikhathi esifushane kunemvula yesigaba sika-σ. Isibonelo, uma i-0.080C-0.4Si-16.9Cr insimbi engagqwali ye-ferritic igcinwa ku-450°C amahora angu-4, ukuqina komthelela wezinga lokushisa kwegumbi kucishe kwehle kufike kuziro. Izinga le-embrittlement liyakhula ngokwanda kokuqukethwe kwe-chromium, kodwa ukuqina bungalulama ngemva kokwelashwa okungaphezu kuka-600 °C. I-embrittlement ku-475°C iwumphumela wokuna kwesigaba se-alpha esicebile nge-chromium. Insimbi enjalo kufanele igweme ukushisa eduze kuka-475°C.

Isikhathi sokuthumela: May-02-2023