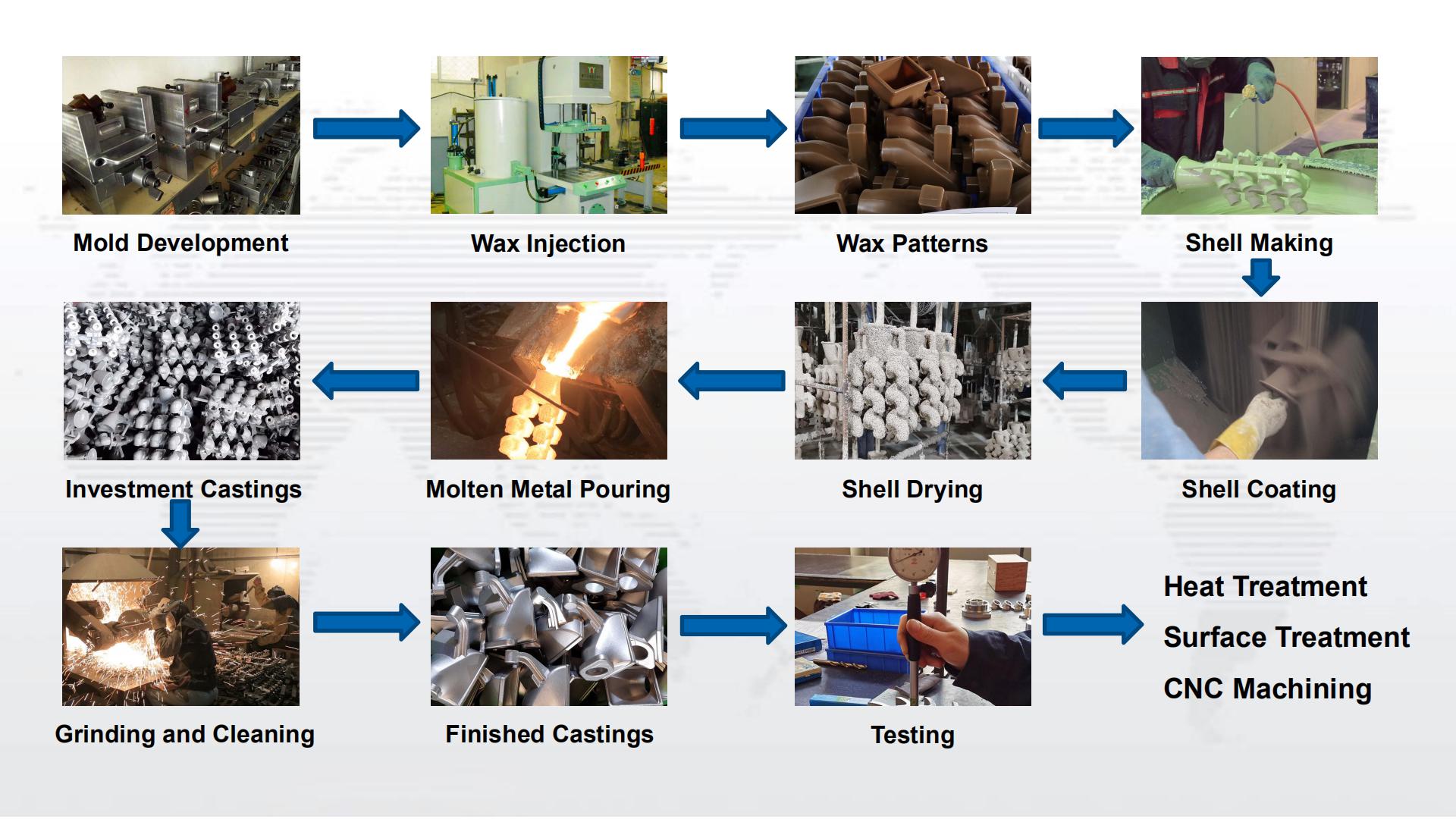

Ukutshala imali, noma ukusakaza okunembayo kwelinye igama, kudinga isethi yemishini ekhethekile njengemishini yokujova i-wax, umshini wokukhipha i-vacuum dewaxing, isithando sokubhaka, isithando somlilo sikagesi neminye imishini yangemuva kokucubungula efana ne-spectrometer, imishini yokuqhumisa isibhamu, ukuwa kanye nemigqa yokuhlanza i-asidi. .. njll. Kwa-RMC Foundry, sisebenzisa ubuchwepheshe bamuva nje kanye nemishini yenqubo esezingeni eliphezulu ezigabeni ezahlukahlukene zenqubo yokutshala imali. Idizayini yamathuluzi, umjovo wephethini ye-wax, ukuhlanganiswa kwephethini ye-wax, ukwenza amagobolondo, ukuthelwa, ukwelapha ukushisa, nokuhlola konke kwenziwa kusetshenziswa imishini etholakalayo engcono kakhulu, esetshenziswa ithimba lethu lochwepheshe abaqeqeshiwe.

Isisetshenziswa Sokujova Ngengcina

I-RMCInvestment Casting Foundryisebenzisa umshini wokujova we-wax ozenzakalelayo ukwenza iphethini ye-wax kanye nomshini wokukhipha i-vacuum ukuze ikhiphe i-wax ecacile ngaphandle kokuguqulwa kwegobolondo lesihlabathi. Imishini yethu yokujova i-wax ikhulisa ukusebenza kahle ekwenzeni iphethini ye-wax. Ingashisisa i-wax eqinile futhi igcine izinga lokushisa olifunayo ngempumelelo. Ukwengeza, ingakwazi ukuphakela i-wax ngokuzenzakalelayo ngosizo lwesistimu yokucindezela. Imishini yethu yokujova i-wax ezenzakalelayo isivumela ukuthi sizuze isivuno esiphezulu sokuphonsa kanye nezikhathi ezincishisiwe zokuhola zokukhiqiza umthamo ophezulu. Ukugcizelela kwethu ku-automation yenqubo kusiza ukunciphisa ubungozi bokuphatha umonakalo. Ngenxa yalobu buchwepheshe bomshini womjovo we-wax othomathikhi, izindleko zabasebenzi zingongiwa kakhulu ngesikhathiinqubo yokutshala imali.

Izithando Zogesi

Ngamaziko kagesi asebenzayo futhi ahlanzekile enqubweni yokufaka utshalomali, indawo yethu yokusebenza iye yathuthukiswa kakhulu kunangaphambili futhi kunezinye izikhungo.

I-Spectrometer Yokuhlaziya Ukwakheka Kwamakhemikhali

I-Spectrometer iyadingeka ngempela kubo bonkei-alloy steel investment castings. Isetshenziselwa ukuhlaziya isithako noma ukwakheka kwamakhemikhali ngaphambi kokuthela insimbi encibilikisiwe. Lokhu kuhlaziya kungaqinisekisa ukuthi ukwakheka kwamakhemikhali ensimbi encibilikisiwe esithandweni somlilo ngasinye kufana nezinombolo ezidingekayo.

Ulayini Wokwelashwa Kokushisa

Ulayini wethu wokwelapha ukushisa uqukethe okokusebenza okuvela kumnikezeli wethu wezixazululo zesithando somlilo wesikhathi eside. Ulayini wethu we-CNC wokwelapha ukushisa ungenza imisebenzi eminingi efana ne-conditioning, isixazululo, ukubuyisela i-carbon, i-carbonitriding, kanye ne-temering ye-carbon steel, insimbi engagqwali, insimbi ephezulu ye-alloy kanye nezinsimbi eziphansi ze-alloy. Ulayini wethu wokwelapha ukushisa usebenza amahora angu-24 ngosuku futhi ulayisha kuphela futhi ulayishwe ngesandla lapho kudingeka.

CNC Machining Equipment

Ukulingisa kwensimbi okunembayo kuhlala kuhilela ukwenziwa kwemishini ye-CNC yokunemba. I-RMC steel investment casting Foundry yake yaba yi-imboni yokulungisa imishinienezinsiza eziphelele zokwenza imishini efana nemishini yokuguqula i-CNC, izinsimbi eziguquguqukayo, imishini yokugaya ye-CNC, umshini wokugaya, umshini wokubhoboza nowokushaya, umshini wokucija, imishini yokujika itafula elula kanye nezikhungo zomshini ze-CNC.

Ukuhlolwa Nokuhlolwa Kwelabhorethri

Yonke imikhiqizo yokulingisa ihlolwa ngokucophelela ngokuhambisana nezinqubo zokuphatha ikhwalithi yangaphakathi ukuze kuqinisekiswe ukuthobelana nemininingwane yamakhasimende nemboni kanye namazinga. Ukuhlola kwethu kuqukethe imishini yokulinganisa emithathu (i-CMM) ekwazi ukuqinisekisa ubukhulu. Siphinde siqashe i-PPAP eqinile futhi sicubungule izinqubo zokuqinisekisa ukugeleza ukuze siqinisekise ikhwalithi yazo zonke izinto ngesikhathi sokukhiqiza. Izinqubo zokugcina zokuhlola ziqhutshekwa futhi nezinhlelo zethu zokuhlola i-X-ray ezizenzakalelayo zeziteshi eziningi. Lokhu kuqinisekisa ukuthi yonke imikhiqizo eshiya indawo yethu ayinazo iziphambeko zangaphakathi ezifana nezikhala, imifantu, izimbobo, noma izinto ezifakwayo ezingafaka engcupheni ubuqotho besakhiwo sengxenye.

Isikhathi sokuthumela: Feb-05-2021