Imikhiqizo yensimbi empunga byinqubo yokukhipha isikhunta sesihlabathikanye nemishini ye-CNC.

Insimbi empunga iqanjwe ngombala ompunga wokuphuka okwakhayo. Insimbi empunga isetshenziselwa izindlu lapho ukuqina kwengxenye kubaluleke kakhulu kunamandla ayo aqinile, njengamabhulokhi amasilinda enjini evuthayo, izindlu zamaphampu, imizimba yamavalvu, amabhokisi kagesi, izisindo zokubala nezinsimbi zokuhlobisa. I-Gray cast iron's high thermal conductivity kanye nomthamo wekhanda othize kuvame ukusetshenziselwa ukwenza i-cast iron cookware nama-disc brake rotor.

Ukwakheka kwamakhemikhali okujwayelekile ukuze uthole i-graphitic microstructure yi-carbon engu-2.5 kuya ku-4.0% kanye ne-silicon engu-1 kuya ku-3%. I-graphite ingase ithathe u-6 kuya ku-10% wevolumu yensimbi empunga. I-silicon ibalulekile ekwenzeni insimbi empunga ngokuphambene nensimbi emhlophe, ngoba i-silicon iyisici sokuzinzisa i-graphite ku-cast iron, okusho ukuthi isiza i-alloy ukukhiqiza i-graphite esikhundleni se-iron carbides; ku-3% i-silicon cishe ayikho ikhabhoni ebanjwe ekuhlanganisweni kwamakhemikhali nensimbi.

I-graphite ithatha isimo se-flake enezinhlangothi ezintathu. Ngezilinganiso ezimbili, njengoba indawo epholile izovela ngaphansi kwesibonakhulu, ama-graphite flakes avela njengemigqa emihle. Amathiphu ama-flakes asebenza njengamanotshi akhona ngaphambili; ngakho-ke, i-brittle. Ukuba khona kwama-graphite flakes kwenza i-Grey Iron ikwazi ukusebenza kalula njengoba ijwayele ukuqhekeka kalula kuma-graphite flakes. I-iron empunga iphinde ibe namandla amahle kakhulu okumanzisa futhi yingakho isetshenziswa kakhulu njengesisekelo sokunyuswa kwamathuluzi omshini.

Grey Cast Iron Mechanical Properties | |||||||

| Into ngokuya nge-DIN EN 1561 | Kala | Iyunithi | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Amandla Okuqina | Rm | I-MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Amandla Esivuno | Rp0,1 | I-MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Amandla Elongation | A | % | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 |

| Amandla Acindezelayo | σdB | I-MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Amandla Acindezelayo | σd0,1 | I-MPa | 195 | 260 | 325 | 390 | 455 |

| Amandla e-Flexural | σbB | I-MPa | 250 | 290 | 340 | 390 | 490 |

| I-Schuifspanning | σaB | I-MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | I-TTB | I-MPa | 170 | 230 | 290 | 345 | 400 |

| Amamojula we-elasticity | E | I-GPa | 78-103 | 88-113 | 103 – 118 | 108 – 137 | 123 – 143 |

| Inombolo ye-Poisson | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Ukuqina kweBrinell | HB | 160-190 | 180 – 220 | 190-230 | 200 - 240 | 210 - 250 | |

| I-Ductility | σbW | I-MPa | 70 | 90 | 120 | 140 | 145 |

| Ukushuba nokucindezela kuyashintsha | σzdW | I-MPa | 40 | 50 | 60 | 75 | 85 |

| Breaking Amandla | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Ukuminyana | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Ukubunjwa kwesihlabathi kusebenzisa isihlabathi esiluhlaza (isihlabathi esimanzi) noma isihlabathi esomile ukwenza izinhlelo zokubumba. Ukukhishwa kwesihlabathi esiluhlaza kuyinqubo yokulingisa endala esetshenziswa emlandweni. Lapho wenza isikhunta, amaphethini enziwe ngokhuni noma ngensimbi kufanele akhiqizwe ukuze enze umgodi ongenalutho. Insimbi encibilikisiwe bese ithululela emgodini ukwenza ukubunjwa ngemva kokupholisa nokuqiniswa. Ukubunjwa kwesihlabathi kubiza kancane kunezinye izinqubo zokulingisa kokubili ekuthuthukisweni kwesikhunta nengxenye yokulingisa iyunithi. Ukubunjwa kwesihlabathi, njalo kusho ukukhishwa kwesihlabathi esiluhlaza (uma kungekho ncazelo ekhethekile). Nokho, namuhla, ezinye izinqubo zokubunjwa nazo zisebenzisa isihlabathi ukwenza isikhunta. Banamagama abo, njengokuthiukubunjwa kwegobolondo, i-furan resin ehlanganiswe nesihlabathi (alukho uhlobo lokubhaka),ukukhishwa kwegwebu elilahlekilekanye ne-vacuum cast.

Amandla Okusakaza Isihlabathi e-RMC Foundry | ||

| Incazelo | Ukubumba ngeManuwali | Ukubunjwa Ngemishini Ezenzakalelayo |

| Usayizi omkhulu Wokusakaza | 1,500 mm × 1000 mm × 500 mm | 1,000 mm × 800 mm × 500 mm |

| Casting Weight Range | 0.5 kg - 1,000 kg | 0.5 kg - 500 kg |

| Amandla Wonyaka | 5,000 amathani - 6,000 amathani | amathani ayi-8,000 - amathani ayi-10,000 |

| Casting Tolerance | Ngesicelo noma Esijwayelekile (ISO8062-2013 noma GB/T 6414-1999) | |

| Izinto Zokubumba | Isihlabathi Esiluhlaza, Isihlabathi Esimbozwe Nge-Resin | |

| Casting Metal & Alloys | I-Grey Iron, I-Ductile Iron, I-Cast Steel, I-Stainless Steel, Ama-Al Alloys, I-Brass, I-Bronze...njll. | |

Izinzuzo zeSand Casting:

- ✔ Izindleko Eziphansi ngenxa yezinto zayo zokubumba ezishibhile nezikwazi ukugaywa kabusha kanye nemishini yokukhiqiza elula.

- ✔ Isilinganiso esibanzi seyunithi ukusuka ku-0.10 kg kuya ku-500 kgs noma ngaphezulu kwalokho.

- ✔ Isakhiwo Esihlukahlukene kusuka ohlotsheni olulula kuya ohlotsheni oluyinkimbinkimbi.

- ✔ Ifanele izidingo zokukhiqiza zobuningi obuhlukahlukene.

Ukubekezelela Okufezwa Ukulingisa Isihlabathi:

Ukubekezelela ukusakaza kuhlukaniswe i-Dimensional Casting Tolerances (DCT) kanye ne-Geometrical Casting Tolerances (GCT). Isikhungo sethu singathanda ukukhuluma nawe uma unesicelo esikhethekile mayelana nokubekezelelana okudingekayo. Lapha okulandelayo yibanga elijwayelekile lokubekezelela esingalifinyelela ngokusakazwa kwesihlabathi esiluhlaza, ukubunjwa kwegobolondo nokusakazwa kwesihlabathi se-furan resin engabhaki:

- ✔ Ibanga le-DCT nge-Green Sand Casting: CTG10 ~ CTG13

- ✔ Ibanga le-DCT nge-Shell Mold Casting noma i-Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ Ibanga le-GCT nge-Green Sand Casting: CTG6 ~ CTG8

- ✔ Ibanga le-GCT nge-Shell Mold Casting noma i-Furan Resin Sand Casting: CTG4 ~ CTG7

Ibanga le-Metal & Alloys lezinqubo zokusakaza kwesihlabathi | |

| Metal & Alloys | Ibanga Elidumile |

| I-Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| I-Ductile (Nodualar) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| I-Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Insimbi Yekhabhoni | C20, C25, C30, C45 |

| I-alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Insimbi engagqwali | I-Ferritic Stainless Steel, i-Martensitic Stainless Steel, i-Austenitic Stainless Steel, Imvula Eqinisa Insimbi Engenasici, i-Duplex Stainless Steel |

| Ama-aluminium Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Ama-alloys asekelwe kwi-Copper / Brass | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Okujwayelekile: ASTM, SAE, AISI, GOST, DIN, EN, ISO, kanye ne-GB | |

-

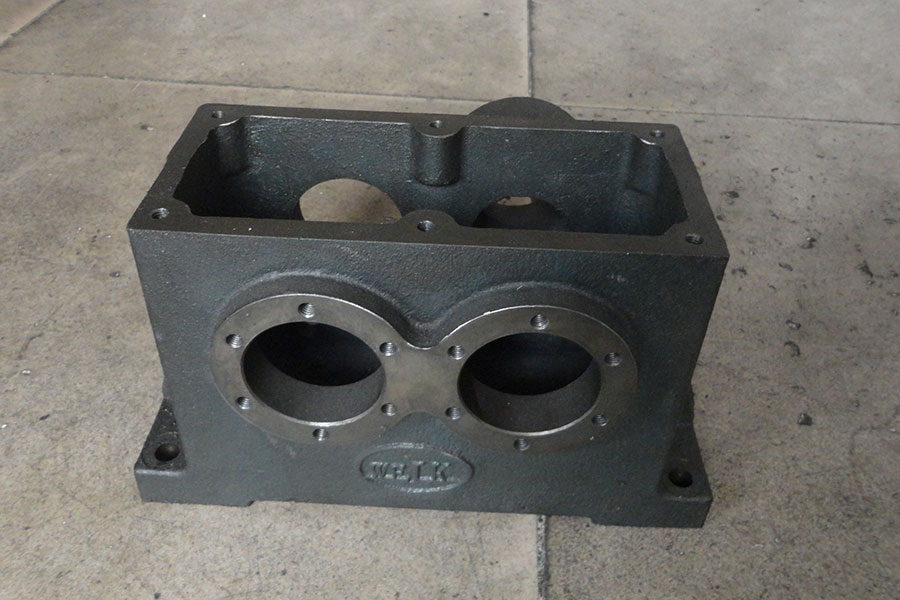

I-Grey Cast Iron Sand Sanding Product

-

Umkhiqizo Wokusakaza we-Grey Cast Iron Shell

-

I-OEM Grey Cast Iron Casting

-

I-alloy Steel Resin Coated Sand Casting Crankshaft

-

Ingxubevange Steel Sand Castings

-

Izingxenye Zeloli Lensimbi ye-Alloy by Sand Casting kanye ne-CNC...

-

Inkampani yeCarbon Steel Sand Casting

-

I-Cast Steel Sand Casting

-

I-Aluminium Alloy Sand Casting