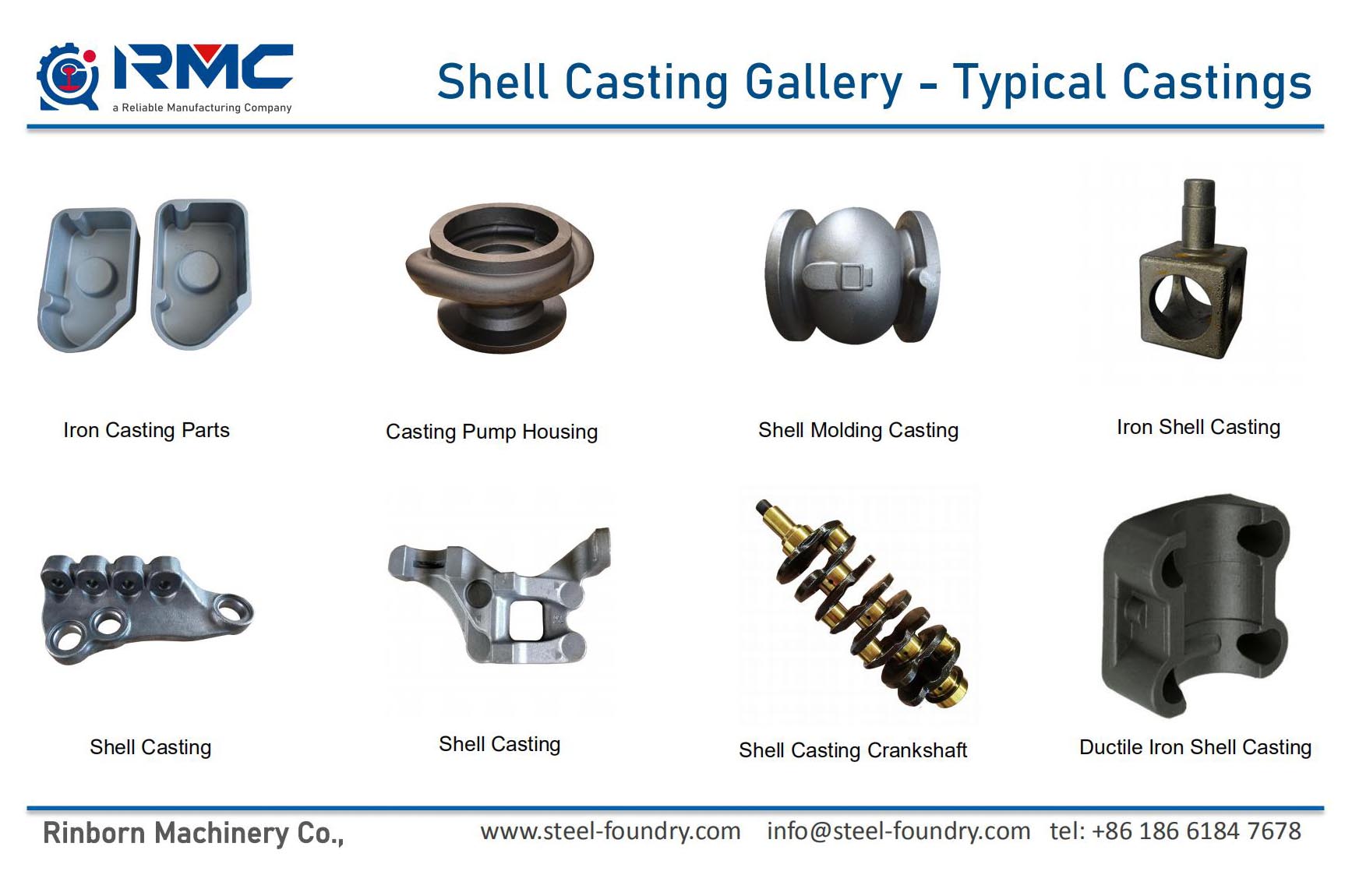

Insimbi empunga yangokwezifisoi-shell mold castingsngezinkonzo zeukwelashwa ukushisakanye nokwelashwa kwendawo.

Ukubunjwa kwegobolondoInqubo ibizwa nangokuthi inqubo yokuphonsa isihlabathi se-resin ehlanganiswe ngaphambili, ukubunjwa kwegobolondo elishisayo noma inqubo yokuphonsa okuyisisekelo. Impahla yokubumba eyinhloko isihlabathi se-phenolic resin esakhiwe ngaphambili, esibiza kakhulu kunesihlabathi esiluhlaza nesihlabathi se-furan resin. Ngaphezu kwalokho, lesi sihlabathi asikwazi ukuphinda sisetshenziswe.

I-Furan resin self-hard-harding sand casting process (inqubo ye-nobake) isebenzisa isihlabathi esimbozwe nge-furan resin ukwenza isikhunta sokuphonsa. Ngemva kokuxuba isihlabathi sokuqala (noma isihlabathi esibuyisiwe), i-liquid furan resin kanye ne-liquid catalyst ngokulinganayo, bese uyigcwalisa ebhokisini eliwumgogodla (noma ibhokisi lesihlabathi), bese uyiqinisa ukuze iqine ibe isikhunta noma isikhunta ebhokisini eliyinhloko (noma isihlabathi. box) ekamelweni lokushisa. Kwabe sekwakhiwa isikhunta sokuphonsa noma umgogodla wokuphonsa, okubizwa ngokuthi ukuziqinisa kwebhokisi elibandayo (umgogodla), noma indlela yokuziqinisa (umgogodla).

Ngenxa yokuthi isikhunta sakhiwe ekamelweni lokushisa futhi asikho isidingo sokushisa, ukukhishwa kwesihlabathi esiziqinisayo kubizwa nangokuthi inqubo yokukhipha okungabhaki. Indlela yokuziqinisa ingahlukaniswa nge-acid-catalyzed furan resin kanye ne-phenolic resin sand self-harding method, i-urethane resin sand self-harding method kanye ne-phenolic monoester self-harding method.

Njengesihlabathi esihlanganisa ibhokisi elibandayo eliziqinisayo, isihlabathi se-furan resin sisekuqaleni futhi okwamanje esisetshenziswa kakhulu isihlabathi esihlanganisayo sokwenziwa e-Chinese foundry. Inani le-resin elengezwe esihlabathini esibumbayo ngokuvamile lingu-0.7% kuya ku-1.0%, kanti inani le-resin eyengeziwe esihlabathini esiwumgogodla ngokuvamile lingu-0.9% kuya ku-1.1%. Okuqukethwe kwe-aldehyde yamahhala ku-furan resin kungaphansi kuka-0.3%, kanti ezinye izimboni zehle zaba ngaphansi kuka-0.1%. Ezindaweni ezisungulwe e-China, isihlabathi esiziqinisayo se-furan resin sesifinyelele ezingeni lamazwe ngamazwe ngaphandle kwenqubo yokukhiqiza kanye nekhwalithi engaphezulu ye-castings.

Insimbi empunga, noma insimbi empunga, iwuhlobo lwensimbi ekhonjiwe ene-graphite microstructure. Iqanjwe ngombala ompunga we-fracture eyakhayo. Insimbi empunga isetshenziselwa izindlu lapho ukuqina kwengxenye kubaluleke kakhulu kunamandla ayo aqinile, njengamabhulokhi amasilinda enjini evuthayo, izindlu zamaphampu, imizimba yamavalvu, amabhokisi kagesi, izisindo zokubala nezinsimbi zokuhlobisa. I-Gray cast iron's high thermal conductivity kanye nomthamo wekhanda othize kuvame ukusetshenziselwa ukwenza i-cast iron cookware nama-disc brake rotor.

Ukwakheka kwamakhemikhali okujwayelekile ukuze uthole i-graphitic microstructure yi-carbon engu-2.5 kuya ku-4.0% kanye ne-silicon engu-1 kuya ku-3%. I-graphite ingase ithathe u-6 kuya ku-10% wevolumu yensimbi empunga. I-silicon ibalulekile ekwenzeni insimbi empunga ngokuphambene nensimbi emhlophe, ngoba i-silicon iyisici sokuzinzisa i-graphite ku-cast iron, okusho ukuthi isiza i-alloy ukukhiqiza i-graphite esikhundleni se-iron carbides; ku-3% i-silicon cishe ayikho ikhabhoni ebanjwe ekuhlanganisweni kwamakhemikhali nensimbi.

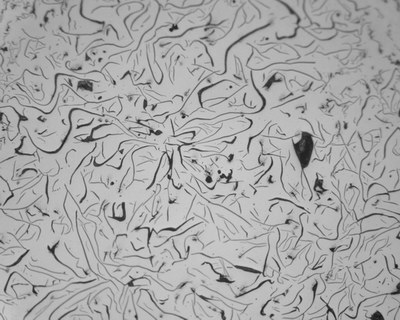

I-graphite ithatha isimo se-flake enezinhlangothi ezintathu. Ngezilinganiso ezimbili, njengoba indawo epholile izovela ngaphansi kwesibonakhulu, ama-graphite flakes avela njengemigqa emihle. Amathiphu ama-flakes asebenza njengamanotshi akhona ngaphambili; ngakho-ke, i-brittle. Ukuba khona kwama-graphite flakes kwenza i-Grey Iron ikwazi ukusebenza kalula njengoba ijwayele ukuqhekeka kalula kuma-graphite flakes. I-iron empunga futhi inamandla amahle kakhulu wokumanzisa futhi yingakho isetshenziswa kakhulu njengesisekelo sokunyuswa kwamathuluzi omshini.

Izakhiwo Zemishini Ye-Grey Cast Iron | |||||||

| Into ngokuya nge-DIN EN 1561 | Kala | Iyunithi | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Amandla Okuqina | Rm | I-MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Amandla Esivuno | Rp0,1 | I-MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Amandla Elongation | A | % | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 |

| Amandla Acindezelayo | σdB | I-MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Amandla Acindezelayo | σd0,1 | I-MPa | 195 | 260 | 325 | 390 | 455 |

| Amandla e-Flexural | σbB | I-MPa | 250 | 290 | 340 | 390 | 490 |

| I-Schuifspanning | σaB | I-MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | I-TTB | I-MPa | 170 | 230 | 290 | 345 | 400 |

| Amamojula we-elasticity | E | I-GPa | 78-103 | 88-113 | 103 – 118 | 108 – 137 | 123 – 143 |

| Inombolo ye-Poisson | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Ukuqina kweBrinell | HB | 160-190 | 180 – 220 | 190-230 | 200 - 240 | 210 - 250 | |

| I-Ductility | σbW | I-MPa | 70 | 90 | 120 | 140 | 145 |

| Ukushuba nokucindezela kuyashintsha | σzdW | I-MPa | 40 | 50 | 60 | 75 | 85 |

| Breaking Amandla | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Ukuminyana | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Ibanga Elilinganayo Le-Grey Cast Iron | ||||||||

| AISI | I-W-stoff | I-DIN | BS | SS | AFNOR | UNE / IHA | I-JIS | I-UNI |

| I-A48-20B | 0.6010 | GG-10 | Ibanga le-100 | 0110-00 | - | - | FC 100 | G10 |

| I-A48-25B | 0.6015 | GG-15 | Ibanga le-150 | 0115-00 | Ngo-15 D | Fg 15 | FC 150 | G15 |

| I-A48-30B | 0.6020 | GG-20 | Ibanga lama-200 | 0120-00 | Ngo-20 D | Fg 20 | FC 200 | G20 |

| I-A48-40B | 0.6025 | GG-25 | Ibanga 250 | 0125-00 | Ngo-25 D | Fg 25 | FC 250 | G25 |

| I-A48-45B | 0.6030 | GG-30 | Ibanga lama-300 | 0130-00 | Ngo-30 D | Fg 30 | FC 300 | G30 |

| I-A48-50B | 0.6035 | GG-35 | Ibanga 350 | 0135-00 | Ngo-35 D | fg 35 | FC 350 | G35 |

| I-A48-60B | 0.6040 | GG-40 | Ibanga 400 | 0140-00 | Ngo-40 D | - | FC 40 | - |

| 32510 | I-GTS-35 | B340/12 | 0815-00 | MN 35-10 | - | I-FCMW 330 | - | |

| I-A220-40010 | 0.8145 | I-GTS-45 | P440/7 | 0852-00 | MN 450 | - | I-FCMP 440/490 | Idatha ye-GMN45 |

| A220-50005 | 0.8155 | I-GTS-55-04 | P510/4 | 0854-00 | MP 50-5 | - | I-FCMP 490 | GMN55 |

| A220-70003 | 0.8165 | I-GTS-65-02 | P570/3 | 0856-00 | MN 650-3 | - | I-FCMP 590 | GMN 65 |

| A220-70003 | - | I-GTS-65 | P570/3 | 0858 | MN 60-3 | - | I-FCMP 540 | - |

| I-A220-80002 | 0.8170 | I-GTS-70-02 | P690/2 | 0862-00 | MN 700-2 | - | I-FCMP 690 | Idatha ye-GMN70 |

I-Resin Coated Sand Casting Metal kanye nama-alloys | |

| Metal & Alloys | Ibanga Elidumile |

| I-Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| I-Ductile (Nodular) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| I-Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Insimbi Yekhabhoni | C20, C25, C30, C45 |

| I-alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Insimbi engagqwali | I-Ferritic Stainless Steel, i-Martensitic Stainless Steel, i-Austenitic Stainless Steel, Imvula Eqinisa Insimbi Engenasici, i-Duplex Stainless Steel |

| Ama-aluminium Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Ama-alloys asekelwe kwi-Copper / Brass | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Okujwayelekile: ASTM, SAE, AISI, GOST, DIN, EN, ISO, kanye ne-GB | |

Imikhiqizo Yokusakaza Yensimbi Yangokwezifiso