Abalingisi ngokwezifisoumkhiqizo wokutshala imali we-duplex wensimbi engagqwalikusuka e-China casting Foundry enemishini, ukwelashwa ngokushisa, nezinsizakalo zokwelashwa kwendawo.

Abalingisi be-RMCizingxenye zensimbi zokunembaezihlala zihlangabezana noma ezeqa okulindelwe ngamakhasimende. Ukufakwa kwe-wax kutshalwa kwezimali okulahlekile kusivumela ukuthi sikhiqize izingxenye zensimbi ezincane ezingamashumi amagremu futhi ezinkulu ezingamashumi amakhilogremu, ngohlu olubanzi lwama-alloys ayinsimbi futhi angeyona ayoni futhi ngokunemba okukhethekile kobukhulu.

Inqubo yokukhipha i-wax elahlekile ikhiqiza izingxenye zensimbi ezinemba eseduze-netha ezivame ukudinga umshini omncane ongeziwe noma ongawudingi. Ukuqeda okuwumphumela nakho kungcono kakhulu kunalokho okufezwa ngezinye izinqubo. Amandla nokuqina kwezingxenye zokusakaza kuzenza zilungele izinhlelo zokusebenza ezimelana nokugqokwa okuphezulu ezidinga izigidi zemijikelezo.

I-Duplex Stainless Steel (DSS) isho insimbi engagqwali ene-ferrite ne-austenite i-accounting ngayinye cishe ngama-50%. Ngokuvamile, okuqukethwe kwezigaba ezincane kudinga okungenani kube ngu-30%. Endabeni yokuqukethwe okuphansi kwe-C, okuqukethwe kwe-Cr kungu-18% kuya ku-28%, futhi okuqukethwe kwe-Ni kungu-3% kuya ku-10%. Ezinye izinsimbi ezingenasici eziyi-duplex nazo ziqukethe izakhi ze-alloying ezifana ne-Mo, Cu, Nb, Ti, kanye no-N.

Ibanga elitholakalayo le-duplex yensimbi engagqwali ku-RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890, 5 A8 A8 A8 A9A 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

I-DSS inezici zensimbi engagqwali ye-austenitic ne-ferritic. Uma iqhathaniswa ne-ferrite, ine-plasticity ephakeme kanye ne-ductility, ayinakho ukushisa kwegumbi, futhi ithuthukise ngokuphawulekayo ukumelana nokugqwala kwe-intergranular nokusebenza kokushisela, kuyilapho igcina i-brittleness, i-thermal conductivity ephezulu, kanye ne-superplasticity njengensimbi engagqwali ye-ferrite. Uma kuqhathaniswa nensimbi engagqwali ye-austenitic, i-DSS inamandla aphezulu futhi ithuthukise kakhulu ukumelana nokugqwala kwe-intergranular kanye nokugqwala kokucindezeleka kwe-chloride. Insimbi engagqwali e-Duplex inokumelana nokugqwala okuhle kakhulu kwe-pitting futhi iyinsimbi engagqwali eyonga i-nickel.

| Ibanga Elilinganayo Lensimbi Engagqwali | |||||||

| AMAQEMBU | AISI | I-W-stoff | I-DIN | BS | SS | UNE / IHA | I-UNI |

| I-Martensitic kanye ne-Ferritic Stainless Steel | 420 C | 1,4034 | I-X43Cr16 | ||||

| 440 B/1 | 1,4112 | I-X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Kr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | I-X6Cr13 | 403 S17 | 2301 | F.3110 | I-X6Cr13 | |

| (410S) | 1.4001 | X7 Kr14 | (403 S17) | 2301 | F.3110 | I-X6Cr13 | |

| 405 | 1.4002 | I-X6 Cll 13 | 405 S17 | - | F.3111 | I-X6 Cll 13 | |

| 416 | 1.4005 | I-X12 CrS 13 | 416 S21 | 2380 | F.3411 | I-X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | I-X12Cr13 | |

| 430 | 1.4016 | X6 Kr17 | 430 S17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Kr13 | 420 S37 | 2303 | F.3402 | I-X20Cr13 | |

| 420F | 1.4028 | X30 Kr 13 | 420 S45 | (2304) | F.3403 | I-X30Cr13 | |

| (420) | 1.4031 | I-X39Cr13 | 420 S45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | I-X20 CrNi 17 2 | 431 S29 | 2321 | F.3427 | I-X16CrNi16 | |

| 430F | 1.4104 | I-X12 CrMoS 17 | - | 2383 | F.3117 | I-X10CrS17 | |

| 434 | 1.4113 | I-X6 CrMo 17 | 434 S17 | 2325 | - | I-X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | I-X6CrTi17 | |

| 409 | 1.4512 | I-X5 CrTi 12 | 409 S17 | - | - | I-X6CrTi12 | |

| I-Austenitic Stainless Steel | 304 | 1.4301 | X5 CrNi 18 9 | 304 S15 | 2332 | F.3551 | I-X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S19 | - | - | I-X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S21 | 2346 | F.3508 | I-X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S12 | 2352 | F.3503 | I-X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | I-X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S31 | 2332 | F.3551 | I-X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S31 | 2333 | F.3551 | I-X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S16 | 2347 | F.3543 | I-X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | I-X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | I-X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S12 | 2367 | - | I-X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S12 | 2337 | F.3553 | I-X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S17 | 2338 | F.3552 | I-X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| I-Duplex Stainless Steel | S32750 | 1.4410 | X 2 CrNiMon 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| I-S31803 | 1.4462 | X 2 CrNiMon 22 5 3 | - | 2377 | - | - | |

| I-S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | I-X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Izinsimbi Ezisansimbi kanye Nezinsimbi Ezingezona Insimbi zeInvestment Casting, Inqubo Yokusakaza Ngengcina Elahlekile:

• I-Grey Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• I-Ductile Iron noma I-Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• I-Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Ama-Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...njll ngesicelo.

• Insimbi Engagqwali: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 kanye nelinye ibanga lensimbi engagqwali.

• Ithusi, Ithusi Elibomvu, Ithusi noma ezinye izinsimbi ezisekelwe ku-Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Okunye Okubalulekile ngokwezidingo zakho ezihlukile noma ngokuya ngamazinga we-ASTM, SAE, AISI, ACI, DIN, EN, ISO, kanye ne-GB

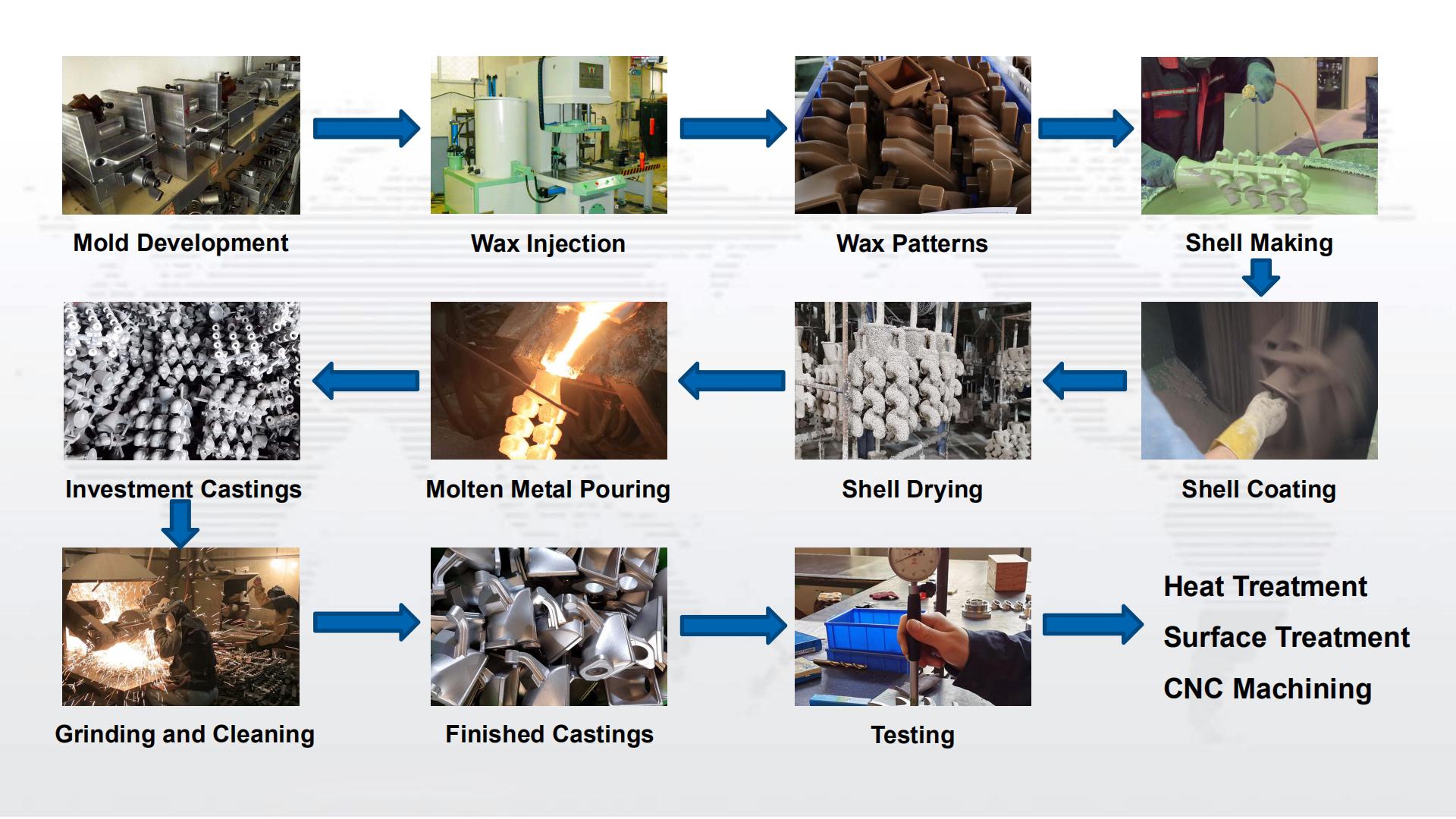

▶ Amakhono weInvestment Casting Foundry

• Ubukhulu Usayizi: 1,000 mm × 800 mm × 500 mm

• I-Weight Range: 0.5 kg - 100 kg

• Amandla onyaka: amathani ayi-2,000

• Izinto Zebhondi Zokwakha I-Shell: I-Silica Sol, Ingilazi Yamanzi kanye nezingxube zayo.

| Amasevisi | Incazelo |

| Amasevisi Okwelapha Angaphezulu | I-Powder Coating, Anodization, Electrophotesis, Chrome Plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, polishing, Bluing, Geormet, Zintek, njll. |

| CNC Precision Machining Services | Lathing, Milling, Turning, Honing, Drilling, Boring, Tapping, Wire Electrode Cutting, Grinding...njll. |

| Ukuhlola Nokulawula Ikhwalithi | I-Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Sealing Pressure Tester, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester...njll. |