I-2205 duplex insimbi engagqwali iyinsimbi engagqwali eyi-duplex eyakhiwe ngo-21% we-chromium, u-2.5% we-molybdenum no-4.5% we-nickel-nitrogen alloy. Izakhiwo ze-ferrite kanye ne-austenite zibalwa cishe ngama-50%. Inamandla aphezulu, ukuqina komthelela omuhle kanye nokumelana nokugqwala okuhle kwengcindezi yendawo yonke. Amandla okukhiqiza we-2205 duplex stainless steel aphindwe kabili kunawe-austenitic stainless steel. Lesi sici senza abaklami behlise isisindo lapho beklama imikhiqizo, okwenza le alloy ingabizi kakhulu kuno-316 no-317L. Le ngxubevange ifaneleka ngokukhethekile ebangeni lokushisa elingu-50°F/+600°F. Kuzinhlelo zokusebenza ezingaphezu kwalolu banga lokushisa, le alloy nayo ingacatshangelwa, kodwa kunemikhawulo ethile, ikakhulukazi uma isetshenziselwa izakhiwo ezishiselwe.

Uma kuqhathaniswa ne-316L kanye ne-317L austenitic stainless steel, i-2205 duplex stainless steel inokusebenza okuphakeme ekumelaneni nokugqwala komgodi kanye nokugqwala kokuqhekeka. Inokumelana nokugqwala okuphezulu. Uma kuqhathaniswa ne-austenitic, yayo I-coefficient yokwandisa okushisayo iphansi futhi ukuqhutshwa kokushisa kuphezulu. Uma kuqhathaniswa nensimbi engagqwali ye-austenitic, ingxube ye-duplex yensimbi engagqwali engu-2205 inamandla acindezelayo aphindwe kabili. Uma kuqhathaniswa ne-316L ne-317L, umklami anganciphisa isisindo sayo. Ingxubevange 2205 ifaneleka ngokukhethekile ebangeni lokushisa elingu -50°F/+600°F. Ngaphansi kwemikhawulo eqinile (ikakhulukazi ezakhiweni ezishiselwe), ingasetshenziswa futhi emazingeni okushisa aphansi.

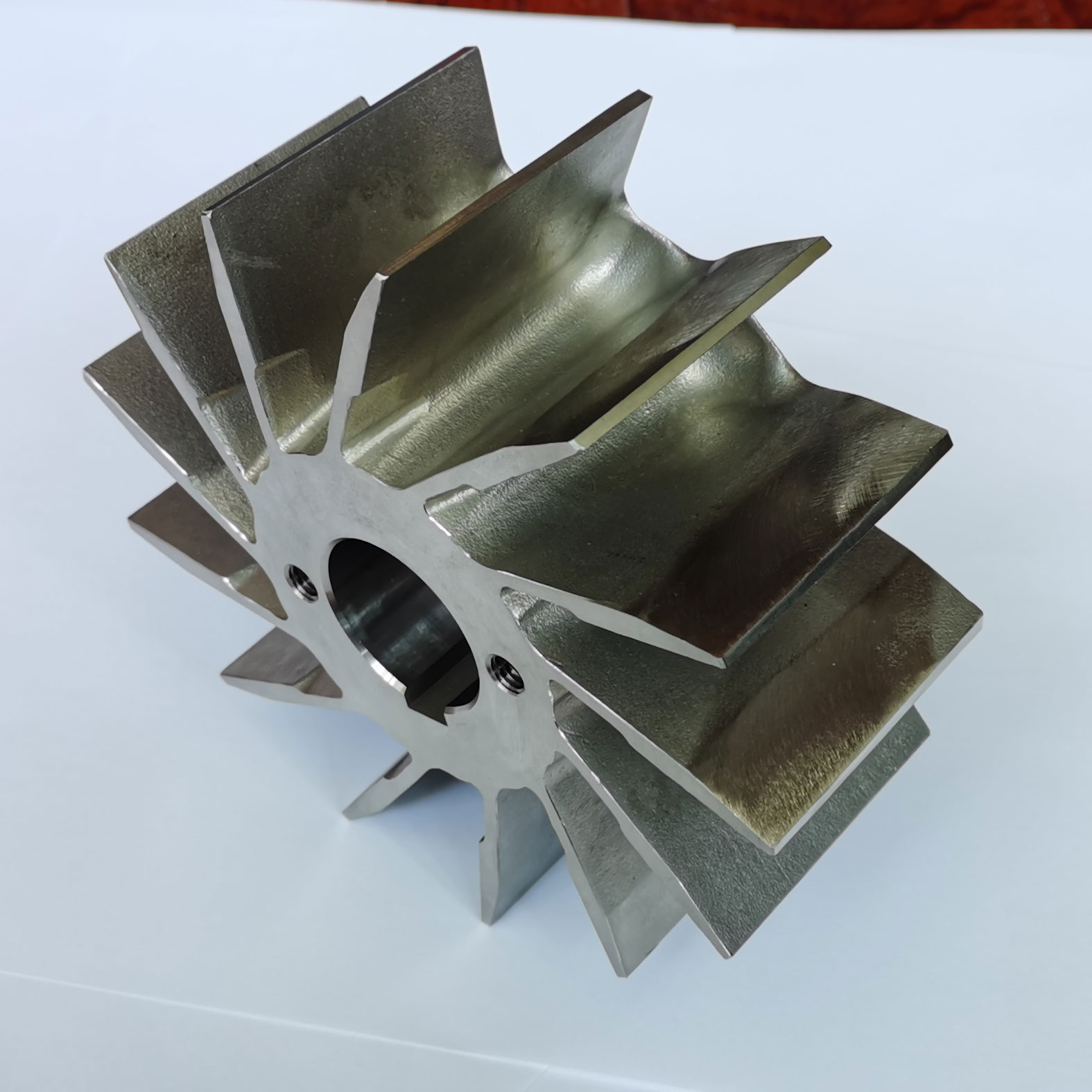

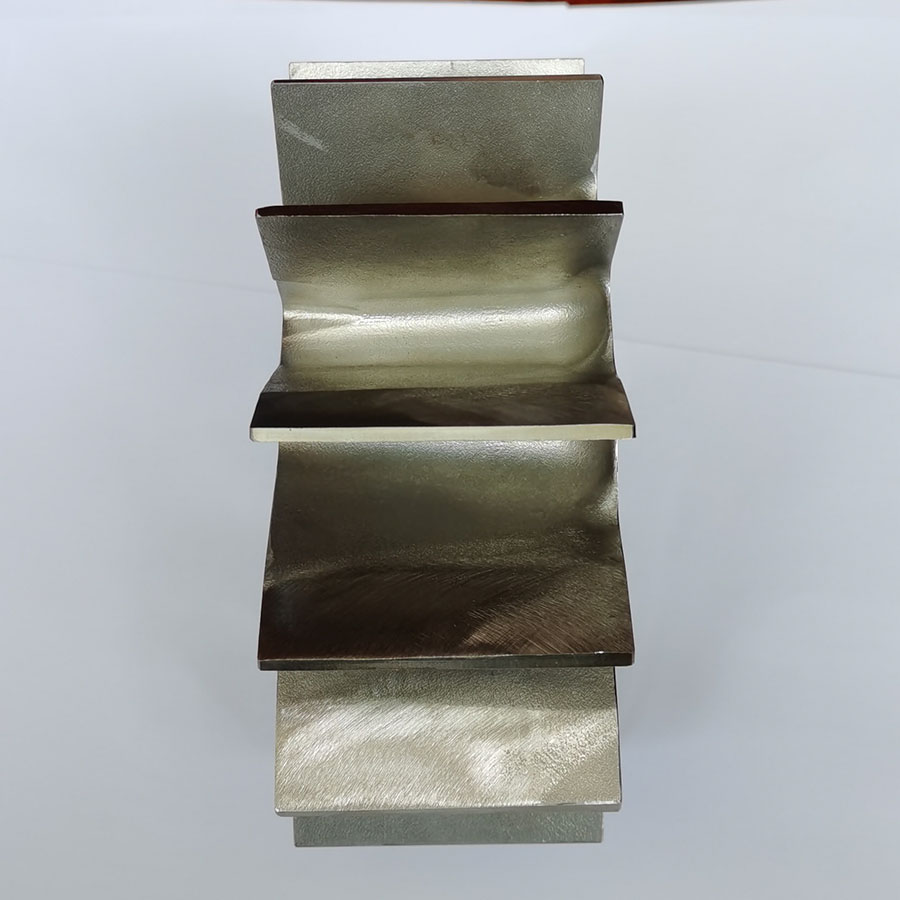

Duplex insimbi engagqwali castingkusho ukubunjwa okwenziwe ngensimbi engagqwali eyi-duplex. I-Duplex Stainless Steel (DSS) isho insimbi engagqwali ene-ferrite ne-austenite i-accounting ngayinye cishe ngama-50%. Ngokuvamile, okuqukethwe kwezigaba ezincane kudinga okungenani kube ngu-30%. Endabeni yokuqukethwe okuphansi kwe-C, okuqukethwe kwe-Cr kungu-18% kuya ku-28%, futhi okuqukethwe kwe-Ni kungu-3% kuya ku-10%. Ezinye izinsimbi ezingenasici eziyi-duplex nazo ziqukethe izakhi ze-alloying ezifana ne-Mo, Cu, Nb, Ti, kanye no-N.

I-DSS inezici zensimbi engagqwali ye-austenitic ne-ferritic. Uma iqhathaniswa ne-ferrite, ine-plasticity ephakeme kanye ne-ductility, ayinakho ukushisa kwegumbi, futhi ithuthukise ngokuphawulekayo ukumelana nokugqwala kwe-intergranular nokusebenza kokushisela, kuyilapho igcina i-brittleness, i-thermal conductivity ephezulu, kanye ne-superplasticity njengensimbi engagqwali ye-ferrite. Uma kuqhathaniswa nensimbi engagqwali ye-austenitic, i-DSS inamandla aphezulu futhi ithuthukise kakhulu ukumelana nokugqwala kwe-intergranular kanye nokugqwala kokucindezeleka kwe-chloride. Insimbi engagqwali e-Duplex inokumelana nokugqwala okuhle kakhulu kwe-pitting futhi iyinsimbi engagqwali eyonga i-nickel.

Ekukhiqizeni ukulingisa, ukubunjwa okuningi kwensimbi engagqwali kuqedwa nguukutshala imali. Ingaphezulu lokulingisa kwensimbi engagqwali okukhiqizwa ukufakwa kwe-investimenti lishelela futhi ukunemba kobukhulu kulula ukulawula. Yiqiniso, izindleko zeutshalomali casting izingxenye zensimbi engagqwaliiphakeme uma iqhathaniswa nezinye izinqubo nezinto zokwakha.

▶ Amakhono weInvestment Casting Foundry

• Ubukhulu Usayizi: 1,000 mm × 800 mm × 500 mm

• I-Weight Range: 0.5 kg - 100 kg

• Amandla onyaka: amathani ayi-2,000

• Izinto Zebhondi Zokwakha I-Shell: I-Silica Sol, Ingilazi Yamanzi kanye nezingxube zayo.

• Ukubekezelelana: Ngesicelo.

▶ Inqubo Yokukhiqiza Eyinhloko Yokutshala Imali

• Dala iphethini ye-wax noma i-replica

• Fafaza iphethini ye-wax

• Tshala iphethini ye-wax

• Susa iphethini ye-wax ngokuyishisa (ngaphakathi kwesithando somlilo noma emanzini ashisayo) ukuze wenze isikhunta.

• Phoqa insimbi encibilikisiwe ithele esikhunjini

• Ukupholisa kanye Nokuqinisa

• Susa i-sprue ekubunjweni

• Qeda futhi upholishe ukufakwa kwe-investimenti okuqediwe