Imikhiqizo yokusakazwa kwe-Aluminium yangokwezifiso ngeinqubo yokuphonsa isihlabathifuthiCNC imishini.

Izinyathelo Zenqubo Yokukhiqiza I-Sand Casting

1. Ukwenza Amaphethini

I-resin noma amaphethini e-aluminium azodingeka enqubo yokukhipha isihlabathi esiluhlaza. Ngaphandle kwamaphethini, ukukhiqizwa kokulingisa ngeke kwenzeke. Ngezinye izikhathi, amaphethini okhuni ayengase asetshenziselwe ukukhiqiza inani elincane, kodwa ekukhiqizeni ngobuningi, amaphethini e-resin noma e-aluminium azofaneleka kakhulu.

2. Inqubo yokubumba

Ukubumba kwesihlabathi esiluhlaza kungenziwa ngezindlela ezintathu ngokuvamile, okuhlanganisa ukubumba ngesandla, umshini wokubumba kanye nemishini yokubumba ezenzakalelayo. Ukubumba ngemanuwali kuyindlela yokubumba yendabuko, kodwa isekhona ngenxa yamandla ayo okukhipha izinto ezinkulu ngezindleko eziphansi. Indlela yomshini wokubumba ingasindisa abasebenzi futhi ikhiqize ukulingwa kwekhwalithi engcono, kodwa ayikwazi ukukhiqiza ama-castings amakhulu ngenxa yomkhawulo wawo wosayizi wamabhokisi esihlabathi.

3. Ukuncibilika Nokuthela Insimbi

Ukuncibilika kungenziwa ngezithando zokungenisa ugesi eziyimvamisa emaphakathi, ezingagcina izinga lihle futhi lizinzile uma liqhathaniswa neziko lendabuko.

4. Ukuqhunyiswa kwesihlabathi nokugaya

Ngemva kokukhishwa kwensimbi yesihlabathi esiluhlaza ekubunjweni kwesihlabathi, kuzodluliselwa ezinyathelweni ezilandelayo ukuze kuqhunyiswe isibhamu noma ukucwiliswa ukuze kukhishwe isihlabathi ne-oxide ngaphandle kwezingxenye zokuphonsa. Khona-ke ama-opharetha azonqamula, ahlanze futhi agaye amakhanda okuvula, izikhuphukeli, imigqa yokuhlukanisa kanye nemiphetho ebukhali.

Ukucutshungulwa okuqhubekayo okunjengokwelashwa kokushisa, ukunemba kwemishini kanye nokwelashwa kwendawo kuzoqhutshwa uma imidwebo noma abasebenzisi bokugcina beyidinga.

I-Aluminiyamu nama-alloys ayo ayengaphonswa futhi athululwe ngokusakazwa kwe-high pressure, i-low pressure die cast, ukuphonsa amandla adonsela phansi, ukuphonsa isihlabathi, ukutshala imali kanyeukukhishwa kwegwebu elilahlekile. Ngokuvamile, ukukhishwa kwe-aluminium alloy kunesisindo esincane kodwa kunokwakheka okuyinkimbinkimbi nendawo engcono.

I-Aluminium Alloy Siyiphonsa Ngenqubo Yokusakaza Isihlabathi:

• I-Cast Aluminium Alloy nge-China Standard: ZL101, ZL102, ZL104

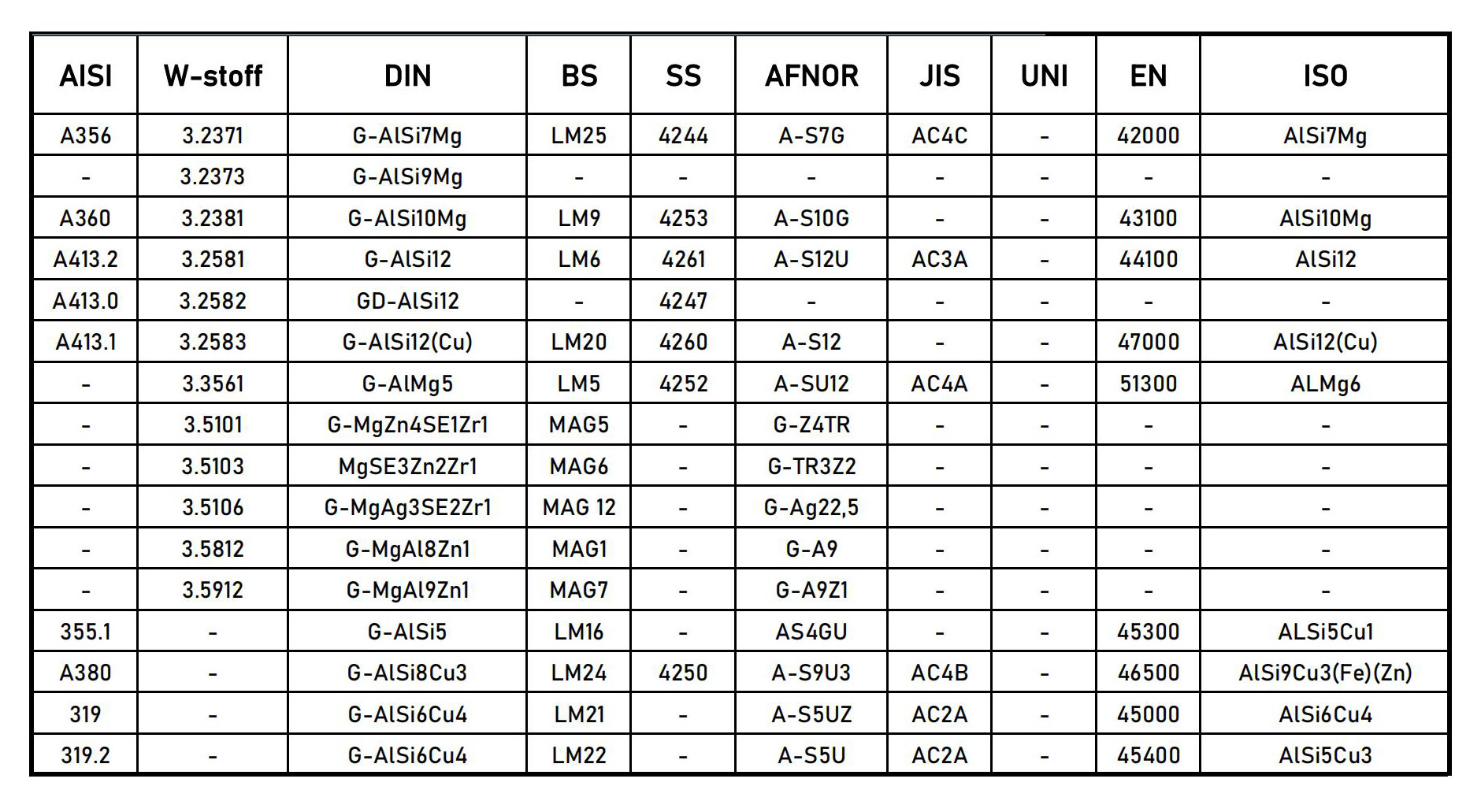

• I-Cast Aluminium Alloy ngu-USA Stardard: ASTM A356, ASTM A413, ASTM A360

• I-Cast Aluminium Alloy ngamanye ama-Starndards: AC3A, AC4A, AC4C, G-AlSi7Mg, G-Al12

| Kuhlanganisiwe | Inhlangano ye-aluminium | Ubulukhuni BHN | Amandla okuqina aphezulu, i-MPa | Isivuno Amandla, MPa | I-Modulus of elasticity, i-GPa | Ukukhathala Amandla, MPa |

| A03550 | AA355.0 | 75-105 | 255 | 185 | 70.3 | 69.0 |

| A03600 | I-AA360.0 | 75.0 | 300 | 170 | 71.0 | 138.0 |

| A03800 | AA380.0 | 80.0 | 317 | 159 | 71.0 | 138.0 |

| A03830 | AA383.0 | 75.0 | 310 | 152 | / | 145.0 |

| A03840 | AA384.0 | 85.0 | 331 | 165 | / | 140.0 |

| A03900 | AA390.0 | 120.0 | 280 | 240 | 81.2 | 140.0 |

| A04130 | I-AA413.0 | 80.0 | 296 | 145 | 71.0 | 130.0 |

| A04430 | AA443.0 | 30-60 | 145 | 48.3 | 71.0 | / |

| A05180 | I-AA518.0 | 80.0 | 310 | 193 | 69.0 | 160.0 |

Izinzuzo ze-Aluminium Alloy Castings:

• Ukusebenza kokulingisa kufana nalokho kokusakazwa kwensimbi, kodwa izici zokumakhenikha ezihlobene zincipha kakhulu njengoba ukushuba kodonga kukhula.

• Ukuqina kodonga lokulingisa akufanele kube kukhulu kakhulu, futhi ezinye izici zesakhiwo ziyefana nalezo zokubunjwa kwensimbi.

• Isisindo esincane kodwa isakhiwo esiyinkimbinkimbi

• Izindleko zokulingisa ngekhilogremu ngayinye yokubunjwa kwe-aluminium ziphakeme kunezokubunjwa kwensimbi nensimbi.

• Uma kukhiqizwa inqubo yokulingisa ifa, izindleko zesikhunta nephethini zingaba phezulu kakhulu kunezinye izinqubo zokulingisa. Ngakho-ke, ukulingwa kwe-aluminiyamu eyi-die casting kungalungela kangcono ukulingwa kwenani elikhulu elifunayo.

| Ukwakheka Kwekhemikhali Okujwayelekile Kwe- Investment Casting Aluminium Alloy nge-North American Specifications | ||||||||||||||

| I-Alloy Grade | Ukucaciswa | Al | Cu | Si | Zn | Mg | Cr | Fe | Mn | Ti | Ag | Be | Ni | P |

| I-A356-T6 | I-AMS 4218 | U-Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.25-0.45 | - | 0.20 | 0.10 | 0.20 | - | -- | - | - |

| awu 357 | I-AMS 4219 | U-Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.40-.70 | - | 0.20 | 0.10 | 0.04-0.20 | - | 0.04-0.07 | - | - |

| F 357 | I-AMS 4289 | U-Bal | 0.20 | 6.5-7.5 | 0.10 | 0.40-.70 | - | 0.10 | 0.10 | 0.04-0.20 | - | 0.002 | - | - |

| E357 | I-AMS 4288 | U-Bal | - | 6.5-7.5 | 0.10 | 0.55-0.60 | - | 0.10 | 0.10 | 0.10-0.20 | - | 0.002 | - | - |

| A201 | I-AMS 4229 | U-Bal | 4.0-5.0 | 0.05 | - | 0.15-0.35 | - | 0.10 | 0.20-0.34 | 0.15-0.35 | 0.40-1.0 | - | - | - |

| C355 | I-AMS 4215 | U-Bal | 1.0-1.5 | 4.5-5.5 | 0.10 | 0.40-0.60 | - | 0.20 | 0.10 ubuningi | 0.20 | - | - | - | - |

| A206 | I-AMS 4235 | U-Bal | 4.2-5.0 | .05 ubuningi | 0.05 ubuningi | 0.20-0.35 | - | 0.10ma | 0.20-0,50 | 0.15-0.30 | - | - | 0.5 ubuningi | - |

| B206 | U-Bal | 4.2-5.0 | .05 ubuningi | 0.05 ubuningi | 0.15-0.35 | - | 0.10 ubuningi | 0.20-0,50 | 0 10 | - | - | 0.5 ubuningi | - | |