Insimbi engagqwali engagqwali, ebizwa nangokuthi i-cast stainless steel, ibhekisela kunsimbi esakhiwe yingxubevange ebonisa ukumelana okuqinile nokugqwala kumithombo yezindaba ethile egqwalayo noma indawo lapho ukugqwala nezici zomshini kuhlangana khona.

| Ukubuka Okusheshayo kwe-Austenitic Stainless Steel | |

| Ukwakheka Kwamakhemikhali Okuyinhloko | Cr,Ni,C,Mo,Cu,Si,Nb,Ti |

| Ukusebenza | I-non-magnetic, ukuqina okuphezulu, ipulasitiki ephezulu, amandla aphansi |

| Incazelo | Insimbi engagqwali enesakhiwo se-austenitic ekamelweni lokushisa |

| Amabanga Omele | 304, 316, 1.4310, 1.4301, 1.4408 |

| Ukusebenziseka kalula | Kuhle |

| Ukushisela | Ngokuvamile kuhle kakhulu |

| Ukusetshenziswa Okujwayelekile | Imishini yokudla, Izingxenyekazi zekhompuyutha, Ukucubungula Amakhemikhali... njll |

Insimbi engagqwali inokuqukethwe kwe-chromium okungenani okungu-10.5%, okuyenza imelane kakhulu nezindawo zoketshezi ezibolayo kanye ne-oxidation. Iyakwazi ukumelana nokugqwala futhi imelana nokugqokwa, ihlinzeka ngokusebenza kahle kakhulu, futhi yaziwa kakhulu ngokubukeka kwayo kobuhle. Ukulingwa kwensimbi engagqwali "ayikwazi ukugqwala" uma kusetshenziswa ezindaweni eziwuketshezi nezihwamuko ezingaphansi kuka-1200°F (650°C) kanye "nokumelana nokushisa" uma kusetshenziswa ngaphezu kwaleli zinga lokushisa.

Insimbi engagqwali ye-Austeniticibhekisela ensimbi engagqwali enesakhiwo se-austenitic ekamelweni lokushisa. Insimbi engagqwali ye-Austenitic ingelinye lamakilasi amahlanu ensimbi engagqwali ngesakhiwo sekristalu (kanye ne-ferritic, martensitic, duplex kanye nemvula eqinisiwe). Kwezinye izindawo, i-austentite insimbi engagqwali ibizwa nangokuthi i-300 series stainless steel. Lapho insimbi iqukethe cishe u-18% Cr, 8% -25% Ni, futhi cishe u-0.1% C, inesakhiwo esizinzile se-austenite. Insimbi engagqwali ye-Austenitic chromium-nickel ihlanganisa insimbi edumile engu-18Cr-8Ni kanye nensimbi yochungechunge lwe-Cr-Ni ephezulu ethuthukiswe ngokwengeza okuqukethwe kwe-Cr ne-Ni kanye nokwengeza i-Mo, Cu, Si, Nb, Ti nezinye izici kulesi sisekelo. Insimbi engagqwali ye-Austenitic ayinamagnetic futhi inokuqina okuphezulu kanye nepulasitiki, kodwa amandla ayo aphansi, futhi akunakwenzeka ukuyiqinisa ngokuguqulwa kwesigaba. Ingaqiniswa kuphela ngokusebenza okubandayo. Uma izakhi ezifana no-S, Ca, Se, Te zengezwa, zinezici ezinhle zokusebenziseka.

Insimbi engagqwali ye-Austenitic nayo ingakhiqiza ama-castings. Ukuze kuthuthukiswe i-fluidity yensimbi encibilikisiwe futhi kuthuthukiswe ukusebenza kokusakazwa, ukwakheka kwealloy yensimbi ecijile kufanele kulungiswe ngokukhuphula okuqukethwe kwe-silicon, kukhuliswe ububanzi bokuqukethwe kwe-chromium ne-nickel, nokukhulisa umkhawulo ongaphezulu wesici sokungcola sulphur.

Insimbi engagqwali ye-Austenitic kufanele iphathwe ngesixazululo esiqinile ngaphambi kokusetshenziswa, ukuze kwandiswe isisombululo esiqinile semvula ehlukahlukene njenge-carbides ensimbi ibe yi-austenite matrix, kuyilapho i-homogenizing isakhiwo futhi iqeda ingcindezi, ukuze kuqinisekiswe ukumelana nokugqwala okuhle kakhulu kanye izakhiwo zemishini. Uhlelo olulungile lokwelapha isixazululo ukupholisa amanzi ngemva kokushisisa ku-1050~1150℃ (izingxenye ezincanyana nazo zingapholiswa ngomoya). Izinga lokushisa lokwelapha isixazululo lincike ezingeni le-alloying yensimbi: I-molybdenum-free noma i-low-molybdenum steel amamaki kufanele abe ngaphansi (≤1100℃), kanye namamaki ahlanganisiwe aphezulu njenge-00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, njll. kufanele abe phezulu ( 1080–1150) ℃).

Ipuleti lensimbi engagqwali i-Austenitic 304, okuthiwa iletha ukumelana nokugqwala okuqinile nokugqwala, futhi linobucwebe obuhle bepulasitiki nokuqina, olulungele ukugxivizwa nokubunjwa. Ngobuningi obungu-7.93 g/cm3, insimbi engagqwali engu-304 iyinsimbi evamile, eyaziwa nangokuthi insimbi engagqwali engu-18/8 embonini. Imikhiqizo yayo yensimbi imelana nokushisa okuphezulu futhi inezindawo ezinhle zokucubungula, ngakho-ke isetshenziswa kakhulu embonini nasezimbonini zokuhlobisa ifenisha kanye nezimboni zokudla nezokwelashwa.

Ibanga Elilinganayo Lensimbi Engagqwali | |||||||

| Izigaba | AISI | I-W-stoff | I-DIN | BS | SS | UNE / IHA | I-UNI |

| I-Martensitic kanye ne-Ferritic Stainless Steel | 420 C | 1.4034 | I-X43Cr16 | ||||

| 440 B/1 | 1.4112 | I-X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Kr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | I-X6Cr13 | 403 S17 | 2301 | F.3110 | I-X6Cr13 | |

| (410S) | 1.4001 | X7 Kr14 | (403 S17) | 2301 | F.3110 | I-X6Cr13 | |

| 405 | 1.4002 | I-X6 Cll 13 | 405 S17 | - | F.3111 | I-X6 Cll 13 | |

| 416 | 1.4005 | I-X12 CrS 13 | 416 S21 | 2380 | F.3411 | I-X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | I-X12Cr13 | |

| 430 | 1.4016 | X6 Kr17 | 430 S17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Kr13 | 420 S37 | 2303 | F.3402 | I-X20Cr13 | |

| 420F | 1.4028 | X30 Kr 13 | 420 S45 | (2304) | F.3403 | I-X30Cr13 | |

| (420) | 1.4031 | I-X39Cr13 | 420 S45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | I-X20 CrNi 17 2 | 431 S29 | 2321 | F.3427 | I-X16CrNi16 | |

| 430F | 1.4104 | I-X12 CrMoS 17 | - | 2383 | F.3117 | I-X10CrS17 | |

| 434 | 1.4113 | I-X6 CrMo 17 | 434 S17 | 2325 | - | I-X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | I-X6CrTi17 | |

| 409 | 1.4512 | I-X5 CrTi 12 | 409 S17 | - | - | I-X6CrTi12 | |

| I-Austenitic Stainless Steel | 304 | 1.4301 | X5 CrNi 18 9 | 304 S15 | 2332 | F.3551 | I-X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S19 | - | - | I-X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S21 | 2346 | F.3508 | I-X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S12 | 2352 | F.3503 | I-X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | I-X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S31 | 2332 | F.3551 | I-X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S31 | 2333 | F.3551 | I-X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S16 | 2347 | F.3543 | I-X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | I-X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | I-X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S12 | 2367 | - | I-X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S12 | 2337 | F.3553 | I-X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S17 | 2338 | F.3552 | I-X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| I-Duplex Stainless Steel | S32750 | 1.4410 | X 2 CrNiMon 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| I-S31803 | 1.4462 | X 2 CrNiMon 22 5 3 | - | 2377 | - | - | |

| I-S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | I-X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Izinto Ezisetshenziswayo Eziyinsimbi Nezingezona Zokutshala Imali, Inqubo Yokusakaza Ngengcina Elahlekile:

- • I-Grey Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • I-Ductile Iron noma I-Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • I-Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

- • Ama-Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...njll ngesicelo.

- • Insimbi Engagqwali: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 kanye nelinye ibanga lensimbi engagqwali.

- • Ithusi, Ithusi Elibomvu, Ithusi noma ezinye izinsimbi ezisekelwe ku-Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Okunye Okubalulekile ngokwezidingo zakho ezihlukile noma ngokuya ngamazinga we-ASTM, SAE, AISI, ACI, DIN, EN, ISO, kanye ne-GB

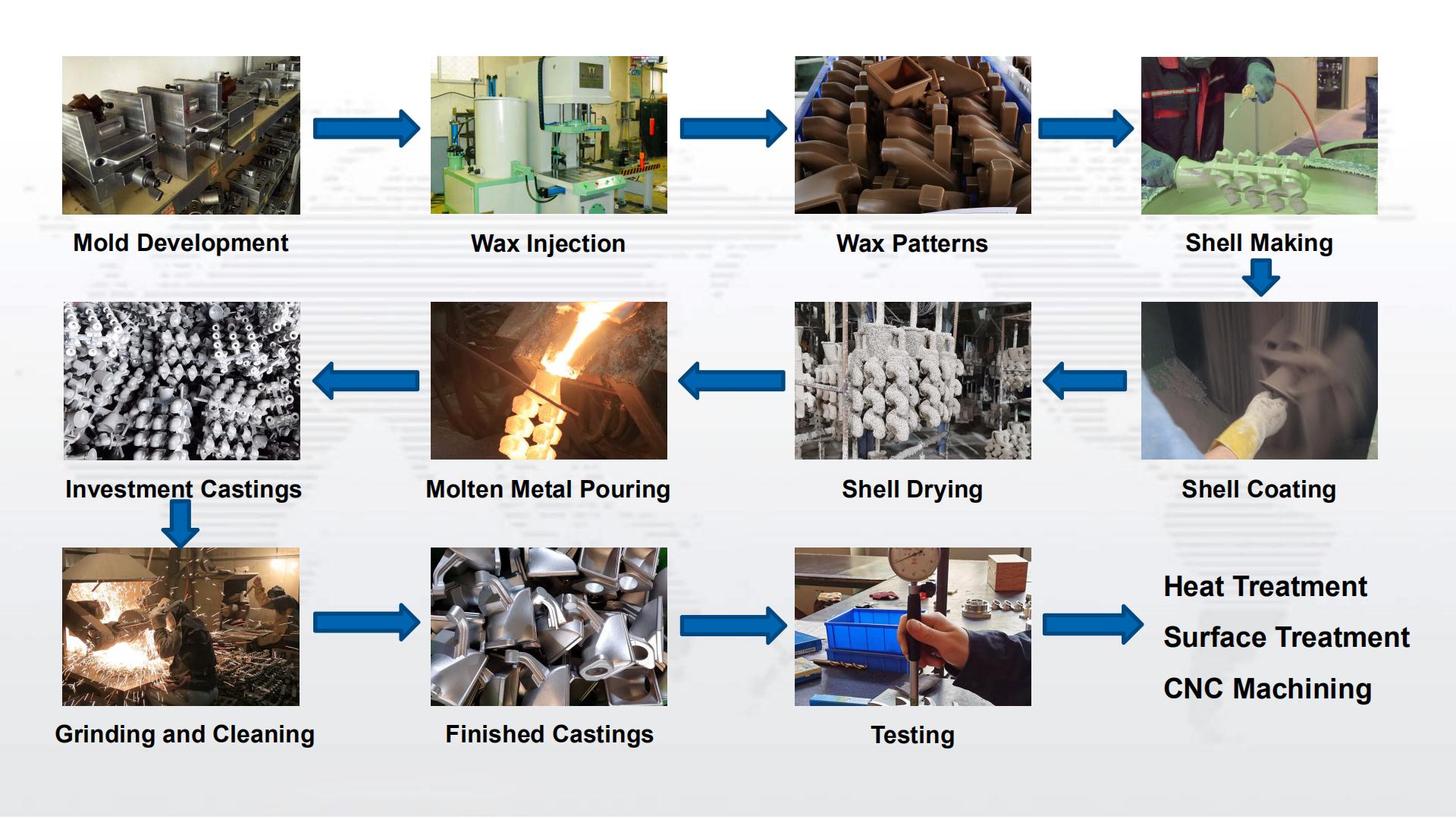

Izinyathelo ezihilelekile kule nqubo noma ukukhishwa kwe-wax okulahlekile yizi:

- • Dala iphethini ye-wax noma i-replica

- • Fafaza iphethini ye-wax

- • Tshala iphethini ye-wax

- • Susa iphethini ye-wax ngokuyishisa (ngaphakathi kwesithando somlilo noma emanzini ashisayo) ukuze wenze isikhunta.

- • Phoqa insimbi encibilikisiwe ithele esikhunjini

- • Ukupholisa kanye Nokuqinisa

- • Susa i-sprue ekubunjweni

- • Qeda futhi upholishe ukufakwa kwe-investimenti okuqediwe

Ukwelashwa Kokushisa Kwe-AISI 316 Stainless Steel Castings:

Shisisa kufike ku-1900°F (1040°C) ubuncane, ubambe isikhathi esanele, cisha emanzini noma uphole ngokushesha ngezinye izindlela. I-AISI 316 ilingana ne-CF8M/F316 kanye ne-Chinese Standard 0Cr17Ni12Mo2. I-AISI 314 iyingxube ye-molybdenum ehambisana ne-AISI 304 alloy futhi ilingana nensimbi eyenziwe nge-CF8M Stainless steel. Ukuba khona kwe-molybdenum kukhulisa ukumelana nokugqwala okujwayelekile kanye nokumelana nokugoba ngama-chloride. Ingxubevange isetshenziswa ezimweni ezine-asidi emnene kanye ne-alkaline nasekuphatheni ama-citric, i-oxalic kanye ne-phosphoric acid.