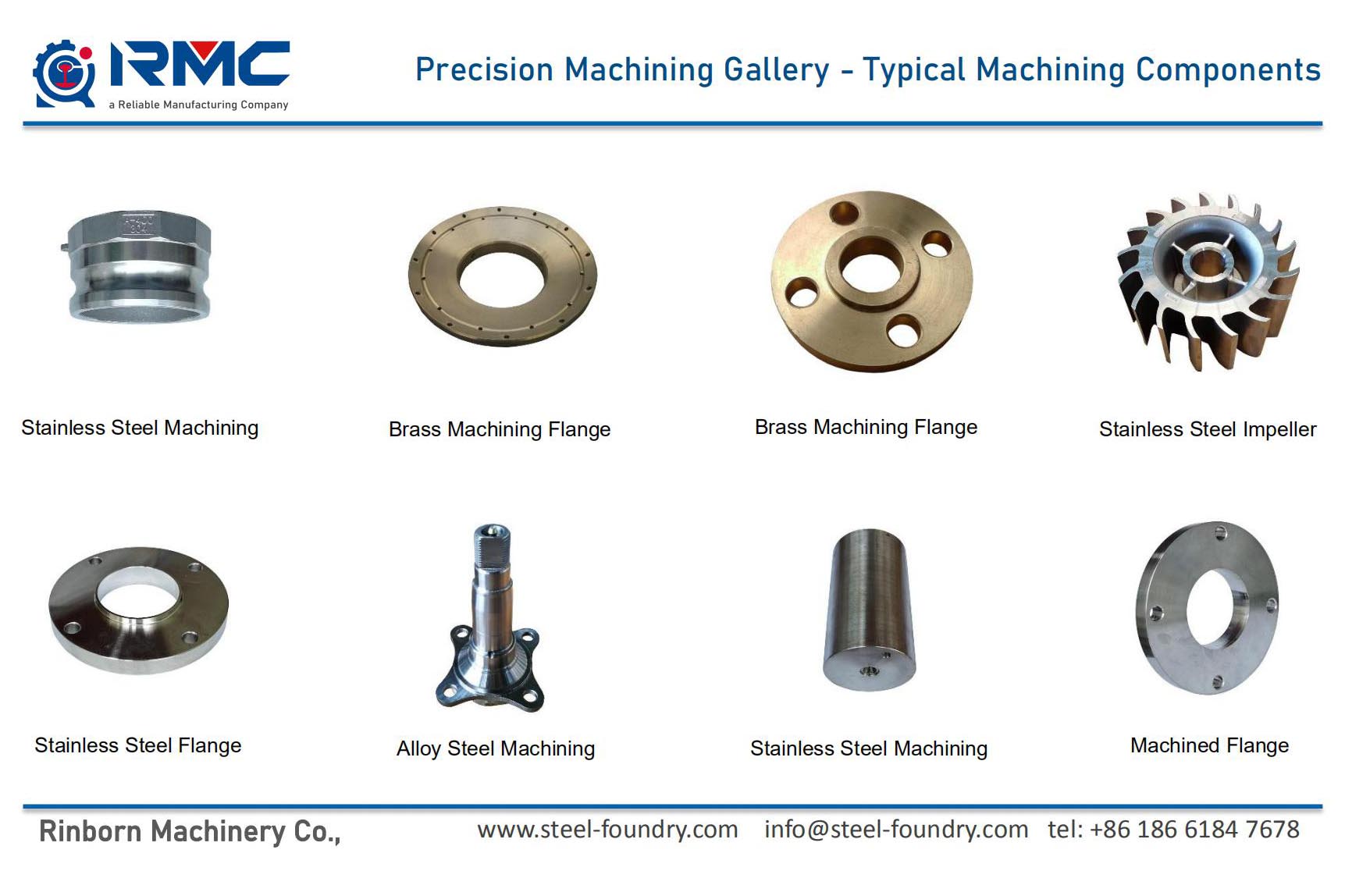

Imikhiqizo yethusi eyenziwe ngomshini ngokunemba ye-CNC ngokusakazwa kwe-investment wax elahlekile, ukwelashwa kokushisa nokuphathwa kwendawo ngokwemidwebo yakho yobunjiniyela kanye nezidingo ezihlukile.

CNC imishiniisho inqubo yokwenza imishini eqhutshwa yiComputerized Numberical Control (CNC ngamafuphi). Isizwa yi-CNC ukuze ifinyelele ukunemba okuphezulu nokungaguquguquki ngezindleko eziphansi zabasebenzi. Ukumayinisa noma yiziphi izinqubo ezihlukahlukene lapho ucezu lwempahla eluhlaza lusikwa lube yisimo sokugcina esifiselekayo kanye nosayizi ngenqubo elawulwayo yokususwa kwempahla. Izinqubo ezinale timu evamile, ukususwa kwezinto ezilawulwayo, namuhla zihlangene zaziwa njengokukhiqiza okukhiphayo, ngokwehlukana nezinqubo zokuhlanganisa izinto ezilawulwayo, ezaziwa njengokukhiqiza okungeziwe.

Impela lokho okushiwo ingxenye “elawulwayo” yencazelo kungahluka, kodwa cishe ngaso sonke isikhathi kusho ukusetshenziswa kwamathuluzi omshini (ngaphezu kwamathuluzi wamandla namathuluzi ezandla). Lena inqubo esetshenziselwa ukukhiqiza eziningiimikhiqizo yensimbi, kodwa ingasetshenziswa nasezintweni ezinjengokhuni, ipulasitiki, i-ceramic, nezinhlanganisela. I-CNC machining ihlanganisa izinqubo eziningi ezihlukene ezifana nokugaya, ukujika, ukuthungatha, ukubhola, ukucija, ukugaya ... njll.

I-Brass ingeyakwa-ingxubevange yethusi-basedfuthi iyingxubevange eyakhiwe ngethusi ne-zinc. I-Brass eyakhiwe ngethusi ne-zinc ibizwa ngokuthi ithusi elijwayelekile. Uma kuyizinhlobonhlobo zama-alloys ezakhiwe izakhi ezingaphezu kwezimbili, kubizwa ngokuthi ithusi elikhethekile. I-Brass iyingxube yethusi ene-zinc njengento eyinhloko. Njengoba okuqukethwe kwe-zinc kwanda, amandla kanye ne-plasticity ye-alloy yanda kakhulu, kodwa izakhiwo zemishini zizokwehla kakhulu ngemva kokudlula i-47%, ngakho-ke okuqukethwe kwe-zinc yethusi kungaphansi kuka-47%. Ngaphezu kwe-zinc, ithusi elikhonjiwe livame ukuqukatha izakhi ze-alloying ezifana ne-silicon, i-manganese, i-aluminium, nomthofu.

| CNC Precision Machining Amakhono | ||||

| Izinsiza | Ubuningi | Ububanzi besayizi | Amandla Wonyaka | Ukunemba Okujwayelekile |

| I-Vertical Machining Center (VMC) | 48 amasethi | 1500mm × 1000mm × 800mm | 6000 ton noma 300000 izingcezu | ±0.005 |

| I-Horizontal Machining Centre (VMC) | 12 amasethi | 1200mm × 800mm × 600mm | amathani angama-2000 noma izingcezu eziyi-100000 | ±0.005 |

| Umshini we-CNC | 60 amasethi | Ubukhulu obushintsha i-dia. φ600mm | 5000 amathani noma 600000 izingcezu | |

| Izinga Eliphelele Lokubekezelela Ukusakaza: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) noma GBT 6414 (China). | ||||

Isikhungo semishini sakhiwe ngomshini wokugaya we-CNC. Umehluko omkhulu emshinini wokugaya we-CNC ukuthi isikhungo somshini sinamandla okushintshanisa ngokuzenzakalelayo amathuluzi omshini. Ngokufaka amathuluzi ngezinjongo ezihlukene kumagazini wamathuluzi, amathuluzi omshini ku-spindle angashintshwa isiguquli sethuluzi esizenzakalelayo ekubambeni okukodwa ukuze kubonakale izici eziningi zokwenza imishini.

Isikhungo somshini we-CNC siyithuluzi lomshini ozishintshayo elisebenza kahle kakhulu elakhiwe imishini yemishini kanye nesistimu ye-CNC futhi ifanele ukucubungula izingxenye eziyinkimbinkimbi. Isikhungo semishini ye-CNC njengamanje singelinye lamathuluzi omshini we-CNC asetshenziswa kakhulu emhlabeni anekhono eliqinile lokucubungula elibanzi. Ingaqedela okuqukethwe okwengeziwe kokucubungula ngemva kokuthi ucezu lokusebenza luboshiwe ngesikhathi esisodwa. Ukunemba kokucubungula kuphezulu. Okwezicucu ze-batch ezinobunzima bokucubungula okuphakathi, ukusebenza kahle kwayo kuphindwe izikhathi ezi-5-10 kunemishini evamile, ikakhulukazi ingaqeda Ukucubungula okuningi okungenakuqedwa ngemishini evamile kulungele kangcono ukucutshungulwa kocezu olulodwa olunobunjwa obuyinkimbinkimbi kanye nezidingo zokunemba okuphezulu noma ukukhiqizwa kwenqwaba encane naphakathi kwezinhlobo eziningi. Igxilisa imisebenzi yokugaya, ukubhora, ukubhola, ukucofa kanye nokusika izintambo kudivayisi eyodwa, ukuze ibe nezindlela ezihlukahlukene zobuchwepheshe.

| Ukuqhathaniswa Kwebanga Lethusi, Ithusi Nethusi | |||||||

| AMAQEMBU | AISI | I-W-stoff | I-DIN | BS | I-JIS | EN | ISO |

| ITHUPHA | I-C10200 | 2.0040 | KWAKu | C103 | I-C1020 | CW008A | I-Cu-OF |

| C11000 | 2.0060 | E-Cu57 | C101 | C1100 | CW004A | Cu-ETP | |

| - | 2.0065 | E-Cu58 | - | - | - | - | |

| C10300 | 2.0070 | SE Ku | - | - | CW021A | - | |

| C12200 | 2.0090 | SF Ku | C106 | C1220 | CW024A | Ku-DHP | |

| C12500 | - | I-Cu-FRTP | C104 | - | I-CR006A | - | |

| C70320 | 2.0857 | - | - | - | I-CW112C | CuNi3Si | |

| C14200 | 2.1202 | SB Ku | C107 | - | - | Cu-AsP | |

| - | 2.1356 | nxa Mn3 | - | - | - | - | |

| - | 2.1522 | Kuthi Si2 Mn | - | - | - | - | |

| C16200 | - | C108 | - | - | CuCd1 | ||

| C18200 | - | I-CC101 | - | CW105C | I-CuCr1 | ||

| C191010 | - | - | - | CW109C | CuNi1Si | ||

| C70250 | - | I-CC102 | - | I-CW111C | CuNi2Si | ||

| C17200 | - | I-CB101 | - | I-CW101C | Cube2 | ||

| C17300 | - | - | - | I-CW102C | I-CuBe2Pb | ||

| C17510 | - | - | - | CW110C | CuNi2Be | ||

| C17500 | - | C112 | - | I-CW104C | I-CuCo2Be | ||

| C15000 | - | - | - | CW120C | KuZr | ||

| C65100 | - | - | - | CW115C | CuSi2Mn | ||

| C65500 | - | I-CS101 | - | I-CW116C | CuSi3Mn1 | ||

| C14500 | - | C109 | - | I-CW118C | CuTeP | ||

| C14700 | - | C111 | - | I-CW114C | I-CuSP | ||

| C18700 | - | - | - | I-CW113C | I-CuPb1P | ||

| ITHUSI | C21000 | 2.0220 | kuZn5 | CZ125 | C2100 | CW500L | - |

| C22000 | 2.0230 | KuZn10 | Cz101 | C2200 | I-CW501L | - | |

| C23000 | 2.0240 | CuZn15 | CZ102 | C2300 | I-CW502L | - | |

| C24000 | 2.0250 | kuZn20 | CZ103 | C2400 | CW503L | - | |

| C25600 | - | kuZn28 | - | - | - | - | |

| C26000 | 2.0265 | KuZn30 | CZ106 | C2600 | CW505L | - | |

| C26800 | 2.0280 | CuZn33 | - | C2680 | CW506L | - | |

| C27200 | - | CuZn36 | - | - | - | - | |

| C27200 | 2.0321 | CuZn37 | CZ108 | C2700 | CW508L | - | |

| C27000 | 2.0335 | CuZn36 | CZ107 | C2700 | I-CW507L | - | |

| C28000 | 2.0360 | CuZn40 | CZ109 | C2800 | CW509L | - | |

| C33500 | - | CuZn37Pb0.5 | - | - | - | - | |

| C34000 | - | I-CuZn35Pb1 | CZ118 | C3501 | - | - | |

| C34500 | 2.0331 | I-CuZn36Pb1,5 | CZ119 | - | I-CW601N | - | |

| C34000 | 2.0331 | I-CuZn36Pb1,5 | CZ119 | C3501 | CW600N | - | |

| C35300 | 2.0371 | CuZn38Pb1,5 | CZ128 | - | - | - | |

| C36500 | 2.0372 | CuZn39Pb0,5 | CZ123 | - | I-CW610N | - | |

| C36000 | 2.0375 | I-CuZn36Pb3 | CZ124 | C3601 | CW603N | - | |

| C37700 | 2.0380 | I-CuZn39Pb2 | CZ 131 / (CZ128) | C3771 | I-CW612N | - | |

| C38500 | 2.0401 | CuZn39Pb3 | CZ121 | C3603 | I-CW614N | - | |

| C38000 | 2.0402 | I-CuZn40Pb2 | CZ122 | - | I-CW617N | - | |

| - | 2.0410 | I-CuZn44Pb2 | CZ130 | - | - | - | |

| C68700 | 2.0460 | I-CuZn20Al2 | CZ110 | - | - | - | |

| C44300 | 2.0470 | I-CuZn28Sn1 | CZ111 | - | - | - | |

| - | 2.0530 | I-CuZn38Sn1 | - | - | - | - | |

| - | 2.0550 | I-CuZn40Al2 | - | - | - | - | |

| - | 2.0561 | I-CuZn40Al1 | - | - | - | - | |

| - | 2.0572 | I-CuZn40Mn2 | CZ136 | - | I-CW723R | - | |

| C61400 | 2.0932 | I-CuAl8Fe3 | - | - | I-CW303G | - | |

| C63000 | 2.0966 | I-CuAl10Ni5Fe4 | I-CA104 | - | I-CW307G | - | |

| ITHUSI | C50700 | 2.1010 | CuSn2 | - | - | - | - |

| C51100 | 2.1016 | CuSn4 | I-PB101 | C5111 | CW450K | - | |

| C51000 | - | CuSn5 | I-PB102 | C5102 | CW451K | - | |

| C51900 | 2.1020 | CuSn6 | I-PB103 | C5191 | CW452K | - | |

| C52100 | 2.1030 | CuSn8 | I-PB104 | C5212 | CW453K | - | |

| - | - | I-CuSn10 | - | - | - | - | |

| - | - | CUSn11 | - | - | - | - | |

| - | - | I-CuSn12 | - | - | - | - | |

Izikhungo zomshini zihlukaniswa zibe izikhungo zokumaka ezivundlile neziqondile ngokuya ngendawo yazo ngesikhathi somshini wokuphotha. Ihlukaniswe ngokuya ngenqubo yokusetshenziswa: isikhungo somshini esiyisicefe nesigaywayo, isikhungo somshini esihlanganisiwe. Ngokusho kokuhlukaniswa okukhethekile kwemisebenzi, kukhona: ibhentshi elilodwa lokusebenzela, ibhentshi lokusebenza eliphindwe kabili kanye nesikhungo sokusebenza se-multi-workbench. Izikhungo zomshini ezine-eksisi eyodwa, i-double-eksisi, i-axis emithathu, i-four-eksisi, i-axis emihlanu kanye nesitoko esishintshashintshayo, njll.

I-CNC machining iwuhlobo lokunemba kwemishini ye-CNC efana nezikhungo zokumachine ezithuthukisiwe ezinesikhungo esiphezulu semishini ye-axis engu-5, isikhungo somshini we-4 axis double platform, noma i-CNC turning lathes engathuthukiswa futhi ibe yisikhungo sokujika se-CNC esinamandla okushintsha okuningi. kunabasiki abayi-15 ngaphakathi kweshifu eyodwa yokubamba; Umshini wokugaya we-CNC kanye nezikhungo zokugaya nokuthinta i-CNC. Ukwenziwa ngokunemba kokusakazwa kwensimbi kuhlukile ekwenziweni kwephrofayili yensimbi. Ukusakaza okunembayo sekuvele kufinyelele umumo oqondile walokho okufiswayo, ngaleyo ndlela kusindisa ukwenziwa kwemishini eminingi uma kuqhathaniswa nomshini osuka kuphrofayela yensimbi ngokuqondile. Futhi ngenxa yalesi sizathu, ngokuvamile kufanele sicabangele indawo yomshini kanye nemvume efanele yomshini ngaphambi kokusakaza. Ukuthenga kwethu okujwayelekile ukwenza umdwebo wokulingisa ongahluziwe kanye nomdwebo womshini ukuze ucacise indawo yomshini kanye nemvume yomshini emdwebeni.

Isikhungo sokusakaza utshalomali se-RMC sihlome ngezikhungo zomshini ze-axis ezi-4, amasethi angu-15 e-CNC turning lathes kanye namasethi ama-3 emishini yokugaya i-cnc, kanye nomsizi ovamile oguquguqukayo, ukugaya, ukutepha, ukubhola kanye nemishini yokugaya, sinamandla okwenza imishini cishe yonke. izinhlobo zensimbi.

Okubizwa nangokuthi ukunemba kwemishini, umshini we-CNC ungafinyelela ukunemba okuphezulu kakhulu ekubekezeleni kwe-geometical nokubekezelelana kobukhulu. Ngemishini yethu ye-CNC kanye Nezikhungo Zomashini Ezivundlile (i-HMC) kanye Nezikhungo Zomashini Eziqondile (VMC), cishe singahlangabezana nawo wonke amabanga akho okubekezela adingekayo.

Amakhono weInvestment Casting Foundry:

• Ubukhulu Usayizi: 1,000 mm × 800 mm × 500 mm

• I-Weight Range: 0.5 kg - 100 kg

• Amandla onyaka: amathani ayi-2,000

• Izinto Zebhondi Zokwakha I-Shell: I-Silica Sol, Ingilazi Yamanzi kanye nezingxube zayo.

• Ukubekezelelana: Ngesicelo.

Izinzuzo zeInvestment Casting Izingxenye:

- Excellent and smooth surface finish

- Ukubekezelelana okuqinile kwe-dimensional.

- Izimo eziyinkimbinkimbi neziyinkimbinkimbi ezinokuguquguquka komklamo

- Ikhono lokuphonsa izindonga ezincane ngakho-ke ingxenye yokusakaza elula

- Ukukhetha okubanzi kwezinsimbi kanye nama-alloys (ayoni futhi angeyona insimbi)

- Uhlaka aludingeki ekwakhiweni kwesikhunta.

- Yehlisa isidingo sokuba machining yesibili.

- Imfucuza yezinto eziphansi.

| UKUBEKEZELEKA KOKUKHISHWA KOKUTSHALWA KWEMALI | |||

| Amayintshi | Amamilimitha | ||

| Ubukhulu | Ukubekezelelana | Ubukhulu | Ukubekezelelana |

| Kufika ku-0.500 | ±.004" | Kufika ku-12.0 | ± 0.10mm |

| 0.500 kuya ku-1.000" | ±.006" | 12.0 ukuze 25.0 | ± 0.15mm |

| 1.000 kuya ku-1.500" | ±.008" | 25.0 ukuze 37.0 | ± 0.20mm |

| 1.500 kuya ku-2.000" | ±.010" | 37.0 kuye ku-50.0 | ± 0.25mm |

| 2.000 kuya ku-2.500" | ±.012" | 50.0 ukuze 62.0 | ± 0.30mm |

| 2.500 kuya ku-3.500" | ±.014" | 62.0 ukuze 87.0 | ± 0.35mm |

| 3.500 kuya ku-5.000" | ±.017" | 87.0 ukuze 125.0 | ± 0.40mm |

| 5.000 kuya ku-7.500" | ±.020" | 125.0 kuya ku-190.0 | ± 0.50mm |

| 7.500 kuya ku-10.000" | ±.022" | 190.0 ukuze 250.0 | ± 0.57mm |

| 10.000 kuya ku-12.500" | ±.025" | 250.0 ukuze 312.0 | ± 0.60mm |

| 12.500 ukuze 15.000 | ±.028" | 312.0 ukuze 375.0 | ± 0.70mm |