I-CNC Machining Factory

Ukucofa imishini kuyinqubo yokusika izingxenye zensimbi ukuze zilingane nezinhlelo zokusebenza nemisebenzi yomsebenzisi wokugcina. Inqubo eminingi yesimanje yokwenza imishini yenziwa yiComputer Numerical Control, i-CNC, lapho amakhompyutha asetshenziswa khona ukulawula ukunyakaza nokusebenza kwezigayo, izinsimbi, neminye imishini yokusika. Le ndlela yokukhiqiza enembayo, ebizwa nangokuthi yi-CNC machining, idlala indima ebalulekile embonini yesimanje yokukhiqiza, ikakhulukazi kwezinye izingxenye zomshini zokunemba okuphezulu.

Kwezinye izinhlelo zokusebenza, njeukusakazanoma ama-forging ngaphandle komshini angafinyelela ukubekezelelana okufunayo kanye nezidingo zangaphezulu. Kodwa-ke, ezimweni eziningi, imishini iyadingeka ukufanisa imininingwane eyingqayizivele yekhasimende futhi uqinisekise ukuthiizingxenye zensimbi eziphelilezingasebenza kahle nezinye izingxenye. Ngisho neizingxenye zokutshala izimali, ezinezinga elingcono kakhulu lezinga eliphezulu lokubekezelela kunezinye inqubo yokwenza insimbi, zisadinga inqubo eyengeziwe yokwenza imishini.

Ukuqinisekisa izinga eliphezulu nokunemba kokuqedwaizingxenye zomshini, izinhlelo zekhompiyutha zibalulekile. I-Computer Aided Design, ebizwa ngokuthi i-CAD ngamafuphi, kanye ne-Computer Aid Manufacturing, ebizwa nge-CAM, zombili zisetshenziswa njengezinhlelo zokuhlinzeka ngeziyalezo ezinemininingwane mayelana nesinyathelo ngasinye senqubo yokunemba yokwenza imishini. Izinhlelo ezifana ne-SolidWorks, i-ProE ne-UG zakha amamodeli e-3D anemininingwane eminingi.

Ngenxa yemishini ethuthukisiwe ye-CNC kanye nezikhungo zemishini ze-axis ezi-4 zazo zombili izinhlobo ezivundlile nezime mpo, i-RMC igxile ekukhiqizeni izingxenye zemishini ze-OEM ezenziwe ngokwezifiso ezinesikhungo somshini, imishini ye-CNC namanye amathuluzi akhethekile njengemidwebo yamakhasimende ngayinye enezidingo zokubekezelelana okuqinile kanye nobulukhuni bomhlaba. Ukubunjwa kwezinsimbi ezisansimbi nezingezona ezoni kwenziwa ngomshini wethuimboni yomshini, okungasisiza sibe nenzuzo enkulu ekulawuleni izindleko nekhwalithi.

CNC Machining Inqubo

Isikhungo Somshini Esiqondile

Esikuzuzisayo nge-CNC Machining

| Izinsiza | Ubuningi | Ububanzi besayizi | Amandla Wonyaka | Ukunemba |

| Isikhungo Somashini se-CNC esime mpo (VMC) | 48 amasethi | 1500mm × 1000mm × 800mm | amathani angama-6000/ngonyaka noma izingcezu ezingama-300000 ngonyaka | ±0.005 |

| I-Horizontal CNC Machining Center (VMC) | 12 amasethi | 1200mm × 800mm × 600mm | amathani angama-2000/ngonyaka noma izingcezu eziyi-100000 ngonyaka | ±0.005 |

| Umshini we-CNC | 60 amasethi | Ubukhulu obushintsha i-dia. φ600mm | 5000 amathani / ngonyaka noma 600000 izingcezu ngonyaka |

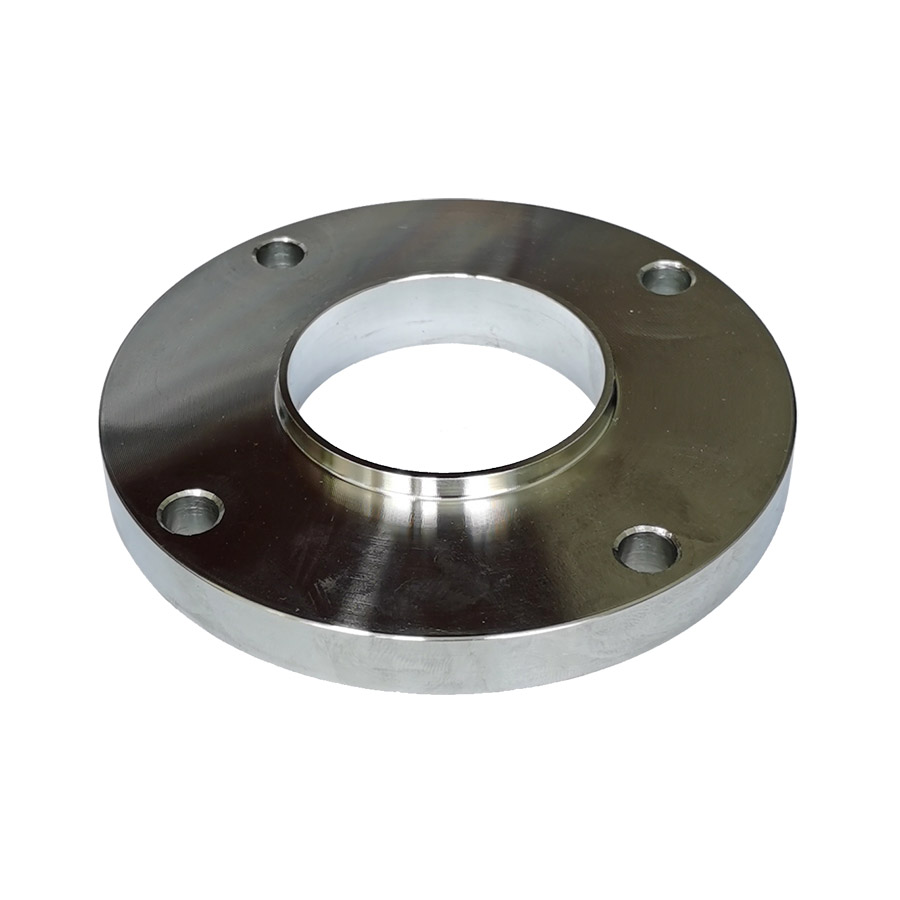

Izingxenye Zomshini zamaHydraulics

Izinhlobo Zensimbi Nama-alloys Enziwe Ngomshini Eworkshop Yethu Yokucupha

• I-iron empunga

• I-Ductile Cast Iron

• I-Carbon Steel evela ku-low carbon steel, i-carbon steel medium kanye ne-high carbon steel.

• Ama-Steel Alloys ukusuka kumabanga ajwayelekile kuya kumabanga akhethekile ngokwesicelo.

• I-Aluminium, iZinc nama-alloys ayo

• Ithusi nethusi

• Insimbi engagqwali, i-Duplex Stainless Steel

• Insimbi Engagugi, Insimbi Engangeni ekuCorrosion, Insimbi Ekwazi ukumelana nokushisa.

• Amaphrofayili Ensimbi kanye namaphrofayili e-Aluminium

• Ingxubevange Forgings

Precision Machining

Yiziphi Izinqubo Zomshini Esingayenza

Izinqubo zomshini ezitholakalayo embonini yemishini ye-RMC CNC ziyi-Turing, Facing, Boring, Milling, Drilling, Planning, Shaping, Grooving, Face Grinding, Cylindrical Grinding, Honing, Gear Hobbing, Threading, Lapping, Tapping...njll.

- Ukuhlonishwa

Le nqubo isebenzisa amadayamitha embobo yokumba asukela ku-0.8 mm kuya ku-100 mm futhi inokujula okufika ku-280 mm. Ukubekezelela komugqa kungu-0.001 mm, ukujikeleza okungu-0.0005 mm, nokuqondile okungu-0.0005 mm. Isiphetho esingaphezulu singu-Ra 0.05 μm. Imishini yokuphotha evundlile neqondile isetshenziswa futhi ihlanganisa i-single-spindle, i-twin-spindle, kanye ne-six-spindle.

- Ukuphenduka

Lena inqubo yokusika iphuzu elilodwa lezicucu eziqinile. Inqubo yethu yokujika kanzima ingakwazi umshini izingxenye ezinobunzima obungaphezu kuka-58 HRC ngemva kokwelashwa kokushisa, ubukhulu obungu-26 mm obuguqukayo, ubude bufike ku-100 mm, ukubekezelelana kobukhulu obungu-0.005 mm, kanye nobulukhuni obungu-Ra0.2μm.

- Ukugaya i-OD ne-ID

Le nqubo isenza sikwazi ukwenza amashafu omshini anobubanzi obungu-750 mm, ubude bungaphakathi kuka-1000 mm, ubuyindilinga obungu-0.0004 mm, kanye ne-cylindricity engu-0.001 mm. Izimbobo zangaphakathi zisukela ku-3 mm kuya ku-100 mm.

- Ukukhipha imali

Amandla okuqeda amandla e-RMC afaka imishini ye-electrochemical, indlela yamandla ashisayo, kanye nemishini yokugeleza kwe-abrasive. Lezi zisetshenziselwa i-hydraulic, i-automotive, ne-aerospace izingxenye ezinezimbobo zokuwela kanye nomgodi ongaphakathi oyinkimbinkimbi ukuze kuhlangatshezwane nezidingo eziqinile zokuqeda.

- OD Ukugaya Okungenaziko

Lokhu kusetshenziselwa ama-shafts anobubanzi obungu-200 mm, ubude obungu-400 mm, ukubekezelelana kobubanzi obungu-0.001 mm, i-cylindricity efika ku-0.0005 mm. Iyatholakala kukho kokubili okuphakelayo kanye nokuphakelayo.

Evundlile Machining Center

I-CNC Machining Workshop

Izisetshenziswa Ezihlelwe Kahle Sithembele Kuwo Kumashini we-CNC Precision

I-CNC Machining Workshop

Precision Machining Process

Umshini we-CNC

I-Machining Factory

Isikhungo Somshini Esiqondile

Evundlile Machining Center

Evundlile Machining Center

CNC Drilling

Iworkshop yomshini

Isevisi yemishini ye-CNC

Isevisi ye-Precision Machining

Isikhungo Somshini

Izicelo ze-CNC Machining Izingxenye

Imikhiqizo yethu isetshenziswa yonkanaizimboninjengezimoto, amahydraulics, izimoto zikaloliwe ezithwala impahla, amaloli athwala kanzima, okokusebenza, ipayipi nephampu, uwoyela negesi, kanye nempahla yezolimo.

| • Izitimela Zesitimela | • Izinto zokusebenza |

| • Amaloli Emisebenzi Enzima | • Izinsiza Zokulima |

| • Ezezimoto | • Ama-hydraulics |

| • Izinto zokwakha | • Engine Systems |

Imikhiqizo Yensimbi ye-CNC Precision Machining

Okungaphezu Kwe-CNC Machining

Njengomhlinzeki wesixazululo esisodwa kanye nomphakeli ophelele weukukhishwa kwesihlabathi, ukufakwa kwe-investimenti, ama-forging kanye nokwenza imishini, sinikeza futhiamasevisiyokwelashwa kokushisa, ukwelashwa kwendawo ngokwethembeka nokuguquguquka. Onjiniyela bethu bagcina amehlo abo enqubweni yokukhiqiza kusukela ekwakhiweni kwephethini kuya emikhiqizweni eqediwe, kanye nempendulo evela kumakhasimende. Amakhasimende athembele kithi ngokuklama kanye nokwesekwa kobunjiniyela, izinto zokwakha kanye nokwesekwa kokukhiqiza okuphathelene nezakhiwo kanye nokucaciswa. Sinamandla angaphakathi we-prototyping asheshayo nokuhlola impahla yasendlini, i-NDT, i-welding, nokwelashwa kokushisa.

Ngakho-ke, izinto esingakwazi ukuzenza zibanzi futhi zikhawulelwe:

- Amasevisi:Idizayini Yephethini, Iziphakamiso Zezindleko Eziphansi, Amathuluzi Nokukhiqiza Iphethini, Amasampuli, Ukukhiqizwa Okuningi, Ukuhleleka, Ngemva Kwesevisi.

- Ukulingisa kanye nokwenza: Investment Casting, I-Sand Casting, Gravity Die Casting, High Pressure Die Casting,I-Shell Molding Casting, Forging, Precision Machining and Metal Fabrications.

- Ukwelashwa kokushisa:Ukucisha, Ukushisa, Ukujwayela, Ukufaka i-Annealing, I-Carburization, I-Nitrotion

- Ukwelashwa kwendawo:I-Anodizing, i-Zinc-plating, iPolising, i-GeoMet, i-Zintek.... njll

- Isevisi yokuhlola:Ukubunjwa Kwekhemikhali, Izakhiwo Zemishini, Ukuhlolwa Kokungena Kwe-Fluorescent noma Uzibuthe (i-FPI, i-MPI), ama-X-ray, Ukuhlolwa kwe-Ultrasonic

Ukuze ufunde kabanzi mayelana nokuthi singasiza kanjani ngezidingo zakho zokusakaza nokwenza imishini noma ukuxoxa ngezinketho, vele ukhululekefinyelela ithimba lethu lonjiniyelanamuhla.

Izingxenye ze-Ductile Iron Machining