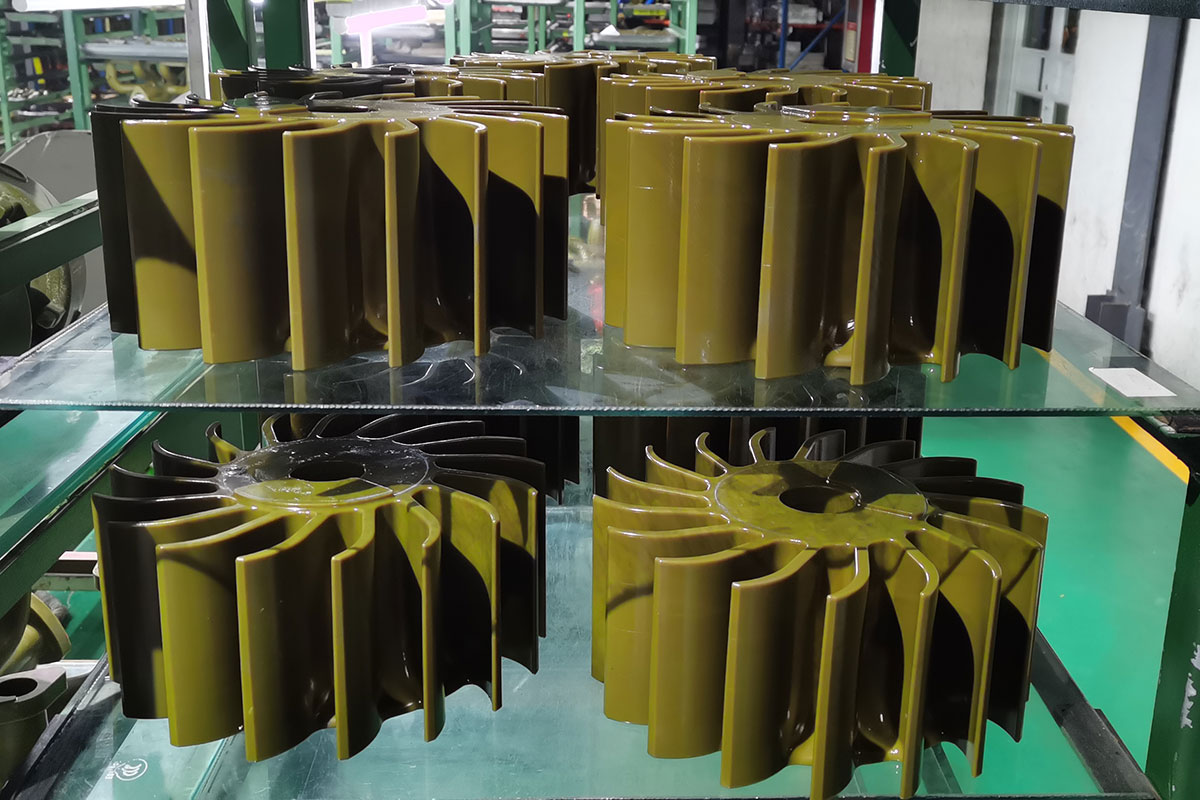

China AISI 304 Stainless Steel Investment Casting Impeller. Izinsizakalo ezenziwe ngezifiso ze-OEM kanyeCNC MachiningZiyatholakala.

Ipuleti lensimbi engagqwali i-Austenitic 304, okuthiwa iletha ukumelana nokugqwala okuqinile nokugqwala, futhi linobucwebe obuhle bepulasitiki nokuqina, olulungele ukugxivizwa nokubunjwa. Ngobuningi obungu-7.93 g/cm3, insimbi engagqwali engu-304 iyinsimbi evamile, eyaziwa nangokuthi insimbi engagqwali engu-18/8 embonini. Imikhiqizo yayo yensimbi imelana nokushisa okuphezulu futhi inezindawo ezinhle zokucubungula, ngakho-ke isetshenziswa kakhulu embonini nasezimbonini zokuhlobisa ifenisha kanye nezimboni zokudla nezokwelashwa.

Isikhungo sethu singakhiqizainkambiso engagqwali utshalomali castingsehambisana ncamashi nencazelo yedizayini yakho. Ngokusakazwa okusukela kumashumi amagremu kuya kumashumi amakhilogremu noma ngaphezulu, sinikeza ukubekezelelana okuqinile kanye nengxenye engaguquki ukuya kokuphindaphindeka kwengxenye.

Ngokujwayelekile, insimbi engagqwali kufanele iphonswe yinqubo yokufaka ngokunemba kokutshala imali nge-silica sol njengebhondi. I-stainless steel silica sol castings inebanga eliphezulu kakhulu lokunemba kwendawo nokusebenza.

Ngenxa yezakhiwo zayo ezibonakalayo eziyingqayizivele, ukulingwa kwensimbi engagqwali kudumile ezinhlobonhlobo zezinhlelo zokusebenza, ikakhulukazi lezo ezisezindaweni ezinokhahlo. Izimakethe ezivamile zokutshala izimali zensimbi engagqwali zihlanganisa uwoyela negesi, amandla oketshezi, ezokuthutha, amasistimu asebenza ngamanzi, imboni yokudla, ihadiwe kanye nezingidi, ezolimo...njll.

Ukutshala imali (i-wax elahlekile) kuyindlela yokunemba yokuphonsa imininingwane yomumo we-net-net usebenzisa ukuphindaphinda kwamaphethini we-wax. Ukutshala imali noma i-wax elahlekile kuyinqubo yokwenza insimbi ngokuvamile esebenzisa iphethini ye-wax ezungezwe igobolondo le-ceramic ukwenza isikhunta se-ceramic. Lapho igobolondo loma, ingcina iyancibilika, kusale isikhunta kuphela. Khona-ke ingxenye yokuphonsa ikhiwa ngokuthululela insimbi encibilikisiwe esikhunjini se-ceramic.

| UKUBEKEZELEKA KOKUKHISHWA KOKUTSHALWA KWEMALI | |||

| Amayintshi | Amamilimitha | ||

| Ubukhulu | Ukubekezelelana | Ubukhulu | Ukubekezelelana |

| Kufika ku-0.500 | ±.004" | Kufika ku-12.0 | ± 0.10mm |

| 0.500 kuya ku-1.000" | ±.006" | 12.0 ukuze 25.0 | ± 0.15mm |

| 1.000 kuya ku-1.500" | ±.008" | 25.0 ukuze 37.0 | ± 0.20mm |

| 1.500 kuya ku-2.000" | ±.010" | 37.0 kuye ku-50.0 | ± 0.25mm |

| 2.000 kuya ku-2.500" | ±.012" | 50.0 ukuze 62.0 | ± 0.30mm |

| 2.500 kuya ku-3.500" | ±.014" | 62.0 ukuze 87.0 | ± 0.35mm |

| 3.500 kuya ku-5.000" | ±.017" | 87.0 ukuze 125.0 | ± 0.40mm |

| 5.000 kuya ku-7.500" | ±.020" | 125.0 kuya ku-190.0 | ± 0.50mm |

| 7.500 kuya ku-10.000" | ±.022" | 190.0 ukuze 250.0 | ± 0.57mm |

| 10.000 kuya ku-12.500" | ±.025" | 250.0 ukuze 312.0 | ± 0.60mm |

| 12.500 ukuze 15.000 | ±.028" | 312.0 ukuze 375.0 | ± 0.70mm |