Kwa-RMC Casting Foundry, samukela iresin camera isihlabathi isikhunta(ayikho inqubo yokubhaka kanye nokuziqinisa) ukuphonsa ithusi, ithusi namanye ama-alloys asekelwe ethusi.

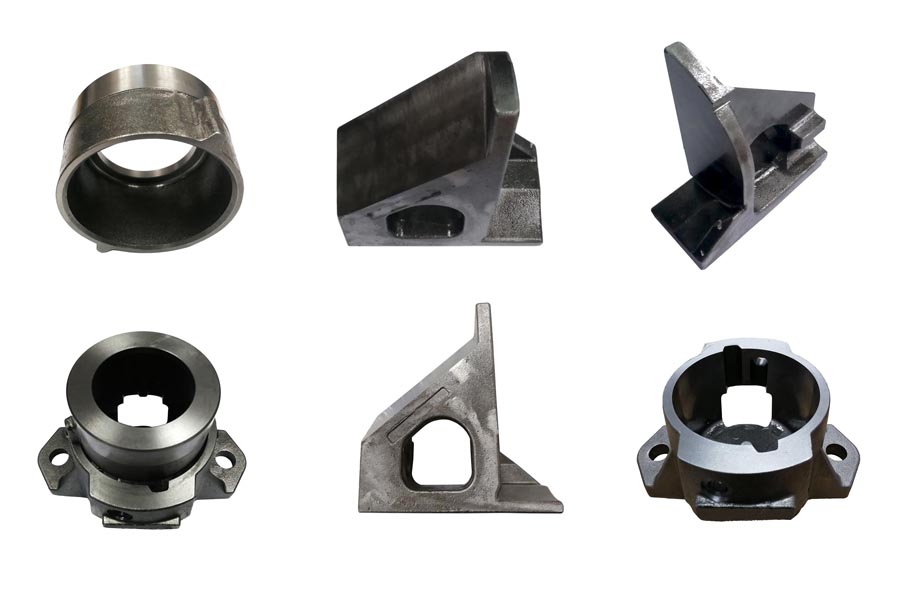

Ama-castings ethusiasetshenziswa kabanzi ku-valve nenkundla yepompo ngenxa yokusebenza okuhle kakhulu kwezinto zethusi. Kwa-RMC Foundry, sikhiqiza ikakhulukazi iama-castings ethusingokujikijelwa kwesihlabathi esiluhlaza, ukujikijelwa kwesihlabathi nge-resin,ukutshala imalifuthi ekubunjweni okukhulu kwethusi, siphinde sithathe inqubo yokuphonsa igwebu elahlekile kanye ne-vacuum casting. Ngokuvamile, ukulingwa kwethusi okukhiqizwa ngokusakazwa kwesihlabathi kuyisigaba esiyinhloko endaweni yethu.

I-alloy yethusi ene-zinc njengengxenye eyinhloko ye-alloying ngokuvamile ibizwa ngokuthi ithusi. I-alloy kanambambili ye-Copper-zinc ibizwa ngokuthi ithusi elijwayelekile, kanti i-ternary, i-quaternary noma i-multi-element yethusi eyakhiwe ngokungeza inani elincane lezinye izakhi ngesisekelo se-alloy yethusi-zinc ibizwa ngokuthi ithusi elikhethekile. I-Cast brass isetshenziselwa ukukhiqiza ithusi lokulingisa. I-Brass castings isetshenziswa kabanzi ekukhiqizeni imishini, i-valve namaphampu, imikhumbi, izindiza, izimoto, ukwakhiwa kanye neminye imikhakha yezimboni, ethatha isisindo esithile ezintweni zensimbi ezisindayo ezingezona ayoni, zakha uchungechunge lwethusi.

Uma kuqhathaniswa nethusi nethusi, ukuncibilika okuqinile kwe-zinc ethusi kukhulu kakhulu. Ngaphansi kokulingana okujwayelekile kwezinga lokushisa, cishe amaphesenti angama-37 e-zinc angancibilika ethusi, futhi cishe u-30% we-zinc angancibilika esimweni sokuphonswa, kuyilapho ithusi eliwuthayela Esimeni sokuphonswa, ingxenye enkulu yokuncibilika okuqinile kwethini. ethusi ku-5% kuya ku-6% kuphela. Ingxenye enkulu ye-solubility eqinile ye-aluminium yethusi i-7% kuya ku-8% kuphela. Ngakho-ke, i-zinc inomphumela omuhle wokuqinisa isisombululo ethusi. Ngesikhathi esifanayo, izakhi eziningi ze-alloying zingaphinde zihlakazwe ngethusi kuya ngamazinga ahlukahlukene , Ngokuqhubekayo uthuthukise izakhiwo zayo zemishini, ukuze ithusi, ikakhulukazi ithusi elikhethekile libe nezici zamandla aphezulu. Intengo ye-zinc iphansi kune-aluminium, ithusi, ne-tin, futhi inothile ngezinsiza. Inani le-zinc elengezwe ethusi likhulu kakhulu, ngakho-ke izindleko zethusi ziphansi kunethusi le-tin ne-aluminium bronze. I-Brass inebanga lokushisa elincane lokuqina, uketshezi oluhle, kanye nokuncibilika okulula.

Ngenxa yokuthi ithusi linezici ezibalulwe ngenhla zamandla aphezulu, intengo ephansi nokusebenza okuhle kokulingisa, ithusi linezinhlobo eziningi, okukhiphayo okukhulu kanye nokusetshenziswa okubanzi kunethusi lethini nethusi le-aluminium kuma-alloys ethusi. Kodwa-ke, ukumelana nokugqwala nokumelana nokugqwala kwethusi akukuhle njengethusi, ikakhulukazi ukumelana nokugqwala nokumelana nokugqoka kwethusi elijwayelekile kuphansi kakhulu. Kuphela lapho ezinye izakhi ze-alloy zengezwa ukuze zenze ithusi elikhethekile elihlukahlukene, ukumelana kwayo nokugqoka nokusebenza kokugqwala kokumelana kuye kwathuthukiswa futhi kwathuthukiswa.

Njengohlobo lwesihlabathi esiziqinisayo, isihlabathi se-furan resin esingabhaki sisetshenziswa kakhulu ukwenza isihlabathi esimpunga se-iron cast kanye nezinqubo zokuphonsa i-ductile iron. Ubuso besikhunta sesihlabathi buzoqiniswa esimweni esinzima ngemva kokushiswa kwengubo. Ngakho-ke, inqubo yokuphonswa kwesihlabathi se-furan resin ingase isetshenziselwe ukukhiqiza izingxenye zensimbi ezinosayizi omaphakathi nezinkulu, kusukela emashumini amakhilogremu kuya emashumini amathani. Ngekhwalithi enhle yangaphezulu, ukubekezelelana okuqinile kanye nokukhubazeka okuncane kokuphonsa, izinqubo zokuphonsa isihlabathi se-furan resin zingasetshenziswa ukukhiqiza izingxenye eziyinkimbinkimbi zokuphonsa.

I-RMC isebenzisa inqubo yokusakazwa kwesanti ye-No-bake ukukhiqiza izinsimbi zensimbi, ukubunjwa kwensimbi engagqwali, ukubunjwa kwe-iron ductile, kanye nezinsimbi ezimpunga. Enqubweni ye-No-Bake, isikhunta sesihlabathi sakhiwe ngephethini yokhuni noma yensimbi. Isihlabathi se-fine-grain sihlanganiswa ne-resin binder kumxube wesihlabathi esinesivinini esikhulu bese uphonsa ebhokisini eliqukethe iphethini. Ngemva kwemizuzu embalwa, ingxube ye-sand-binder iyaziqinisa futhi isikhunta siyasuswa emaphethini. I-Sand Cores yokudala isakhiwo sangaphakathi se-castings yenziwa kusetshenziswa inqubo efanayo ngesikhathi esifanayo. Ngemva kokuba ama-cores kanye nokubunjwa kwangaphandle kuhlanganiswe, zivalwa futhi zilungiselelwe ukuthululwa kwensimbi. Izinto ezithile, njenge-ductile iron castings, zidinga ukwelashwa okukhethekile kwensimbi ngaphambi kokuthululwa. Inqubo ye-No-Bake casting iguquguquka kakhulu njengoba ivumela ukulingwa kwensimbi kanye nokubunjwa kwensimbi ukuthi kugcinwe ukuze kubekezelelane okunembile ngenkathi futhi ikwazi ukuphatha izingxenye zosayizi ukusuka kumashumi amagremu kuze kufike emashumini amathani.

Izinyathelo Zokusingathwa Kwe-Bake Shell Casting:

Akukho kubhaka kuyinqubo yokuphonsa ehilela ukusetshenziswa kwezibophezelo zamakhemikhali ukuze kuhlanganiswe isihlabathi esibumbayo. Isihlabathi sihanjiswa endaweni yokugcwalisa isikhunta silungiselela ukugcwaliswa kwesikhunta. I-mixer isetshenziselwa ukuhlanganisa isihlabathi ne-chemical binder kanye ne-catalyst. Njengoba isihlabathi siphuma ku-mixer, i-binder iqala inqubo yamakhemikhali yokuqina. Le ndlela yokugcwalisa isikhunta ingasetshenziswa engxenyeni ngayinye yesikhunta (ukubhekana nokudonsa). Ingxenye ngayinye yesikhunta ibe isihlanganiswa ukuze yakhe isikhunta esiqinile nesiminyene. I-rollover ibe isetshenziselwa ukususa uhhafu wesikhunta ebhokisini lephethini. Ngemva kokuba isihlabathi simisiwe, ukugeza isikhunta kungase kusetshenziswe. Ama-cores, uma kudingeka, asethwe ekuhuduleni futhi i-cope ivaliwe phezu kwama-cores ukuze kuqedelwe isikhunta. Uchungechunge lwezimoto ezibamba isikhunta kanye nama-conveyor ahambisa isikhunta endaweni yokuthululwa. Uma isitheliwe, isikhunta sivunyelwa ukuba siphole ngaphambi kokunyakaziswa. Inqubo yokunyakazisa ihilela ukuhlephula isihlabathi esibunjiwe kude nokubunjwa. Ukulingisa bese kuqhubekela endaweni yokuqedela yokulingisa ukuze kukhishwe isikhuphukeli, ukuqedela ukusakaza nokuphothulwa. Izingcezu eziphukile zesihlabathi esibunjiwe ziphinde zihlakazwe kuze kube yilapho isihlabathi sibuyiselwa kusayizi wokusanhlamvu. Isihlabathi manje singabuyiselwa ukuze sisetshenziswe kabusha enqubweni yokulingisa noma sisuswe ukuze silahlwe. Ukulungiswa kabusha kwe-thermal kuyindlela ephumelela kakhulu, ephelele yokungatholi kabusha kwesihlabathi sokubhaka.

| Izinto zokwakha ze-Shell Mold Casting e-RMC Foundry | |

| Metal & Alloys | Ibanga Elidumile |

| I-Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| I-Ductile (Nodualar) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| I-Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Insimbi Yekhabhoni | C20, C25, C30, C45 |

| I-alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Insimbi engagqwali | I-Ferritic Stainless Steel, i-Martensitic Stainless Steel, i-Austenitic Stainless Steel, Imvula Eqinisa Insimbi Engenasici, i-Duplex Stainless Steel |

| Ama-aluminium Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Ama-alloys asekelwe kwi-Copper / Brass | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Okujwayelekile: ASTM, SAE, AISI, GOST, DIN, EN, ISO, kanye ne-GB | |