I-cast iron, ehlanganisa ikakhulukazi i-grey cast iron, i-ductile cast iron, i-cast mealleable iron nezinye i-high alloy cast iron, isetshenziswa kabanziI-RMC Casting Foundry. I-cast iron castings idlala indima ebalulekileizimboni zesimanje. Ukukhetha izinqubo zokuphonsa ezifanele nezifanelekile ezenziwe ngensimbi ekhonjiwe kuzokusiza ukuthi uthole ukukhishwa kwensimbi ngezindleko eziphansi kanye nesikhathi esifushane sokuhola.

Lapha kulokhu okulandelayo siphakamisa izimiso noma izici lapho sikhethaizinqubo zokuphonsa ezifaneleokwensimbi okusansimbi. Ngokuvamile, inqubo yokuphonsa insimbi esetshenziswa kakhulu ukubunjwa kwesihlabathi, kulandelwa izindlela ezikhethekile zokuphonsa, njengokubunjwa kwensimbi, ukubunjwa kokutshalwa kwezimali, ukubunjwa kwegobolondo,ukukhishwa kwegwebu elilahlekilekanye ne-vacuum cast.

1- Ukusakaza Kwesanti Kufanele kube Ukukhetha Kokuqala

Ikakhulukazi ngenxa yezindleko eziphansi kanye nokukhiqizwa okulula kweinqubo yokuphonsa isihlabathi, ukubunjwa kwesihlabathi kuthathe cishe u-60% kuya ku-70% wengqikithi yokukhiqiza, futhi cishe u-70% wawo ukuphonsa kwesihlabathi esiluhlaza. Lapho isihlabathi esiluhlaza singakwazi ukuhlangabezana nezidingo bese ungase ucabangele ukusetshenziswa kwesihlabathi esomile noma esinye isihlabathi. Ububanzi besisindo sokubunjwa kwesihlabathi esiluhlaza busuka kumakhilogremu amaningana kuya kumakhulu amakhilogremu, kuyilapho ukukhiqizwa kokubunjwa kobumba okomile kungaba nesisindo samathani amaningana.

Inqubo yokuphonsa isihlabathi isebenzisa izinhlobo zesihlabathi ukwenza isikhunta esibunjiweyo. Ingase futhi ihlukaniswe ngezinhlobo ezintathu:

1) I-Green Sand Casting, esebenzisa isihlabathi esimanzi (esiluhlaza) ukwakha isikhunta.

2) I-Resin Coated Sand Castingkanye No-Bake Sand Mold Casting (Ukuziqinisa Kwe-Resin Sand Casting), ezisebenzisa izinto eziboshwe ngamakhemikhali ukuze zisize ukwakha izinhlelo zokubumba.

3) I-Dry Sand Casting, esebenzisa ngokuyinhloko okomile ngaphandle kwezinto zamakhemikhali zokubumba. Inqubo yokukhipha isihlabathi esomile ngokuyinhloko ibhekisela ekulahlekeni kwegwebu elilahlekile kanyeukukhishwa kwe-vacuum.

Ngokuvamile, ekubunjweni kwensimbi okuphakathi nendawo nokukhulu, ukubunjwa kwesihlabathi se-resin esiziqinisayo kungaba inketho enhle. Kodwa mayelana nensimbi ye-alloy ne-carbon steel materials, singakhetha isihlabathi sengilazi yamanzi. Lokhu kungathola ubukhulu obunembile, indawo ebushelelezi yokulingisa, kuyilapho ngezindleko eziphansi kunenqubo yokufaka utshalomali ye-silica sol.

Ukunemba, ukuphela kwendawo, ukuminyana kwezinto ezibonakalayo kanye nesakhiwo esincane, izakhiwo zemishini zingase zingafinyeleli ku-requriemenets eqinile uma unokulindela okukhethekile nokuphezulu. Kulesi simo, ezinye izindlela zokuphonsa ezifana ne-silica sol noma ukutshala imali kwengilazi yamanzi, ukukhishwa kwefa, ukukhishwa kwengcindezi ephansi, ukukhishwa kwegwebu elilahlekile kanye nokukhishwa kwe-vacuum kufanele kuthathwe emehlweni ethu.

2- Cabanga Ngesidingo Sonyaka

Uma isidingo sakho sonyaka siphezulu, ulayini wokubumba ozenzakalelayo kufanele ube yisinqumo esingcono kakhulu ngenxa yomthamo wawo omkhulu wokukhiqiza kanye nekhwalithi engaguquki. Futhi le ndlela ingafinyelela izindleko ezimaphakathi eziphansi kuphela uma inani elidingekayo likhulu ngokwanele. Ngenkathi, ukubumba ngesandla kuzokonga izindleko zakho uma inani lakho lingelikhulu kangako, noma ukulingisa okufunayo kuwusayizi omaphakathi noma omkhulu.

Kodwa-ke, isikhunta sesihlabathi se-resin (ukubunjwa kwegobolondo) inqubo yokubunjwa nayo ifanele ukubunjwa kwensimbi yobukhulu obukhulu. Ngaphezu kwalokho, ukukhishwa kwegobolondo kunokugcina okungcono kanye nekhwalithi ephakeme kunezinqubo zokuphonsa isihlabathi esiluhlaza.

Ezinye izinqubo ezifana ne-low pressure die casting, i-die casting, i-centrifugal casting ifaneleka kuphela ukukhiqizwa ngobuningi ngobuningi obukhulu ngenxa yemishini ebizayo namathuluzi.

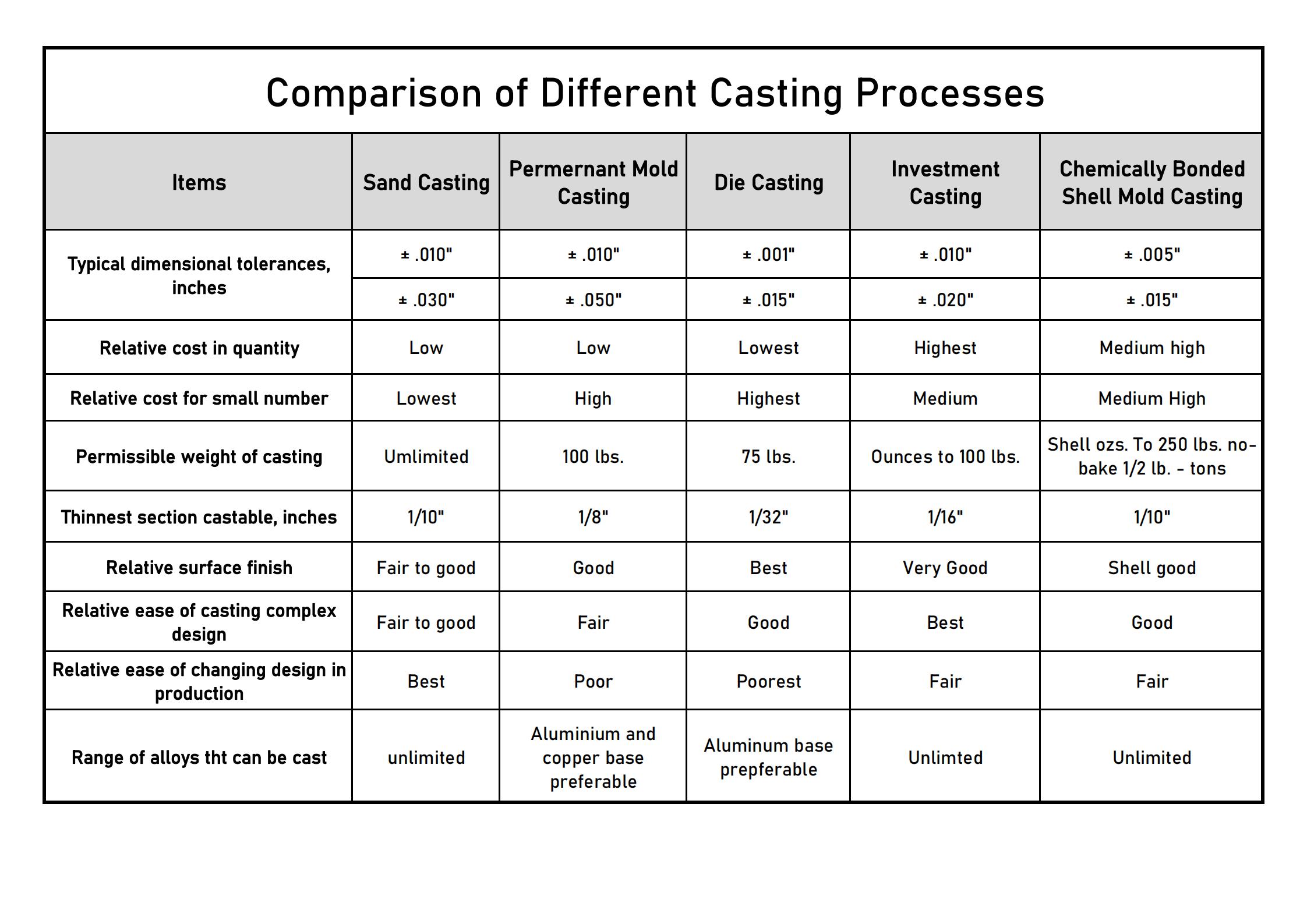

3- Ukubekezelelana Kobukhulu kanye nokubala kwekhwalithi yobuso

Enqubweni yokukhetha inqubo yokuphonsa yensimbi ekhonjiwe, ukunemba kobukhulu kanye nekhwalithi yobuso nakho kubalulekile. Ukukhetha aukunemba inqubo yokulingisakuzonciphisa isidingo somshini, ngisho nangaphandle komshini. Lokhu kudinga ukucatshangelwa okuphelele kwebhalansi phakathi kokwenyuka kwezindleko zokusakaza kanye nokwehliswa komshini. Ngokusekelwe kulwazi lwethu lweminyaka eminingi, onjiniyela benkampani yethu bangakukhethela inqubo yokulingisa efaneleke kakhulu neyongayo.

Isikhathi sokuthumela: Jan-28-2021