Ukubekezelela i-Dimensional kuyisici esibalulekile lapho sikhetha inqubo yokulingisa yokulingisa esikufunayo. Kumadokhumenti ajwayelekile e-ISO 8062 (ehambisana ne-GB/T6414-1999) yaseChina, amazinga okubekezelela obukhulu bokusakaza acaciswe ngokucacile. Ngokuvamile, ukufakwa kwe-investimenti kanye ne-die casting kunokunemba okuphezulu kobukhulu futhi yingakho inqubo yokutshala imali ibizwa nangokuthi.ukunemba kokulingisa. Lapha kokulandelayo uzobona ukubekezelelwa okuvamile kokulingisa ngezinqubo ezahlukene zokulingisa.

Ukubekezelela Kokusakaza Namakhono kwa-RMC Foundry | ||||||

| Inqubo Yokusakaza | Amandla Wonyaka / Amathani | Izinto Ezibalulekile | Isisindo Sokusakaza | I-Dimensional Casting Tolerance Grade (ISO 8062) | Ukwelashwa Kokushisa | |

| I-Green Sand Casting | 6000 | I-Grey Cast Iron, I-Ductile Cast Iron, Cast Al, Brass, Cast Steel, Stainless Steel | 0.3 kg kuya ku-200 kg | I-CT11~CT14 | Normalization, Ukucisha, Tempering, Annealing, Carburization | |

| I-Resin Coated Sand Casting (I-Shell Casting) | 0.66 lbs ukuya ku-440 lbs | I-CT8~CT12 | ||||

| I-Wax Investment Casting elahlekile | Ukusakaza Kwengilazi Yamanzi | 3000 | Insimbi engagqwali, Insimbi ye-Carbon, i-alloy Steel, i-Brass, i-Aluminium, i-Duplex Stainless Steel, i-Cast Iron | 0.1 kg kuya ku-50 kg | I-CT5~CT9 | |

| 0.22 lbs ukuya ku-110 lbs | ||||||

| I-Silica Sol Casting | 1000 | 0.05 kg kuya ku-50 kg | CT4~CT6 | |||

| 0.11 lbs ukuya ku-110 lbs | ||||||

| Ukusakaza Kwegwebu Elilahlekile | 4000 | I-Grey Iron, I-Ductile Iron, I-alloy, I-Carbon Steel, Insimbi Engagqwali, I-Brass, i-Al | 10 kg kuya ku-300 kg | I-CT8~CT12 | ||

| 22 lbs kuya ku-660 lbs | ||||||

| I-Vacuum Casting | 3000 | Insimbi empunga, i-Ductile Iron, i-alloy Steel, i-Carbon Steel, i-Stainless Steel | 10 kg kuya ku-300 kg | I-CT8~CT12 | ||

| 22 lbs kuya ku-660 lbs | ||||||

| I-High Pressure Die Casting | 500 | Ama-Aluminium Alloys, Ama-Zinc Alloys | 0.1 kg kuya ku-50 kg | I-CT4~CT7 | ||

| 0.22 lbs ukuya ku-110 lbs | ||||||

Casting Tolerances forI-Sand Castings

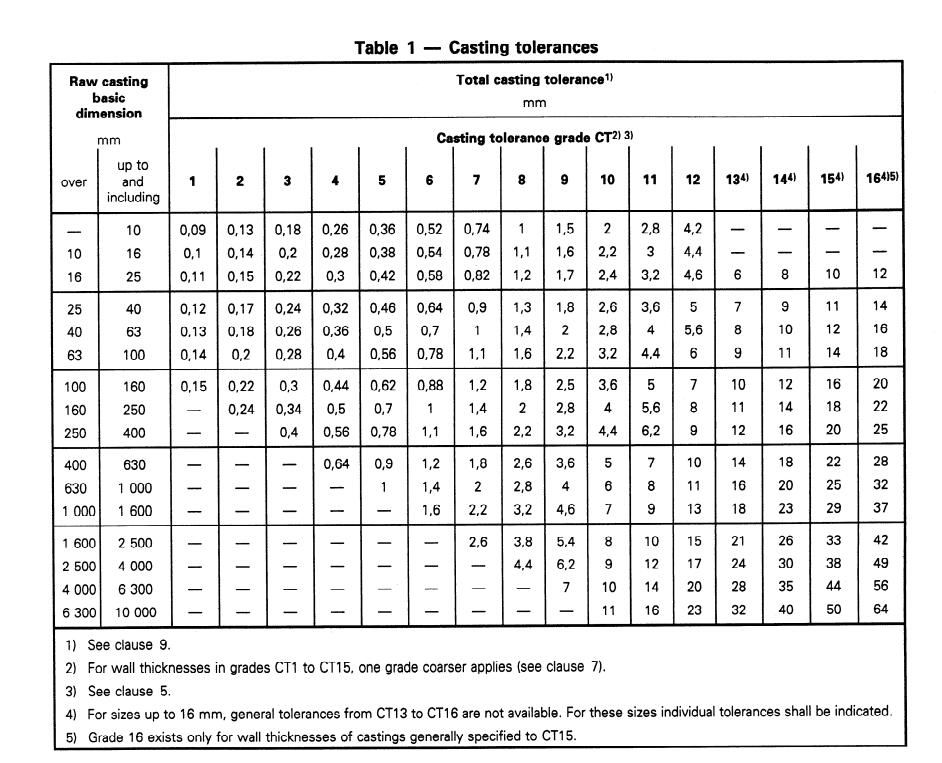

Ukubekezelela ukusakaza kuhlukaniswe i-Dimensional Casting Tolerances (DCT) kanye ne-Geometrical Casting Tolerances (GCT). Isikhungo sethu singathanda ukukhuluma nawe uma unesicelo esikhethekile mayelana nokubekezelelana okudingekayo. Lapha okulandelayo yibanga elijwayelekile lokubekezelela esingalifinyelela ngokusakazwa kwesihlabathi esiluhlaza, ukubunjwa kwegobolondo nokusakazwa kwesihlabathi se-furan resin engabhaki:

- ✔ Ibanga le-DCT nge-Green Sand Casting: CTG10 ~ CTG13

- ✔ Ibanga le-DCT nge-Shell Mold Casting noma i-Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ Ibanga le-GCT nge-Green Sand Casting: CTG6 ~ CTG8

- ✔ Ibanga le-GCT nge-Shell Mold Casting noma i-Furan Resin Sand Casting: CTG4 ~ CTG7

Casting Tolerances forInvestment Castings

Ngokwezinto ezihlukene zokuhlanganisa ezisetshenziselwa ukwenza igobolondo, ukufakwa kwe-investimenti kungahlukaniswa kube yi-silica sol casting kanye nengilazi yamanzi. Inqubo yokusakazwa kwe-silica sol yokutshala imali inokubekezelela okungcono kwe-Dimensional Casting (DCT) kanye nokubekezelelana kwe-Geometrical Casting (GCT) kunenqubo yengilazi yamanzi. Nokho, ngisho nangenqubo efanayo yokulingisa, iBanga Lokubekezelela lizohluka ku-alloy ngayinye ngenxa yokwehlukahlukana kwazo. Isikhungo sethu singathanda ukukhuluma nawe uma unesicelo esikhethekile mayelana nokubekezelelana okudingekayo. Lapha kulokhu okulandelayo yibanga lokubekezelelana okujwayelekile esingalifinyelela kokubili nge-silica sol casting kanye nezinqubo zokuphonsa ingilazi yamanzi ngokuhlukana:

- ✔ Ibanga le-DCT nge-Silica Sol Lost Wax Casting: DCTG4 ~ DCTG6

- ✔ Ibanga le-DCT nge-Water Glass Lost Wax Casting: DCTG5 ~ DCTG9

- ✔ Ibanga le-GCT le-Silica Sol Lost Wax Casting: GCTG3 ~ GCTG5

- ✔ Ibanga le-GCT nge-Water Glass Lost Wax Casting: GCTG3 ~ GCTG5

Ukubekezelela Kokusakaza Kwe-Shell Mold Castings

Njengoba sishilo ekubekezeleni ukubunjwa kokubunjwa kwesihlabathi, ukukhishwa kwesikhunta segobolondo kunokunemba okuphezulu kakhulu nokubekezelelana okuqinile kunokubunjwa kwesihlabathi. Lapha okulandelayo yibanga elijwayelekile lokubekezelela esingalifinyelela ngokusakazwa kwesikhunta segobolondo nokusakazwa kwesihlabathi se-furan resin engabhaki:

- ✔ Ibanga le-DCT nge-Shell Mold Casting noma i-Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ Ibanga le-GCT nge-Shell Mold Casting noma i-Furan Resin Sand Casting: CTG4 ~ CTG7

Ukubekezelela Ukusakaza Kokusakaza Kwegwebu Elilahlekile

Ngokuvamile, ukubekezelelwa kokusakazwa kwegwebu elilahlekile kungcono kunokujikijela kwesihlabathi, kodwa kubi kakhulu kunokubunjwa kwegobolondo kanye nezinqubo zokuphonsa ezingabhaki. Ngesisekelo sethu, singafinyelela amabanga alandelayo okusakaza. Kodwa sithanda ukukhuluma nawe ngabalingisi abathile bese sinquma ukuthi yiziphi izinombolo esingakunikeza zona.

- ✔ Ibanga le-DCT ngokusakazwa kwegwebu elilahlekile: CTG9 ~ CTG13

- ✔ Ibanga le-GCT ngokusakazwa kwegwebu elilahlekile: CTG5 ~ CTG8

Uma umdwebo wokulingisa noma idokhumenti yenqubo yokulingisa idinga ngokusobala ukuhlolwa kwazo zonke izilinganiso zokulingisa, zonke izilinganiso zokulingisa zidinga ukuhlolwa. Lesi simo ngokuvamile siyingxenye yokuqala yokukhiqizwa kokulingisa noma inqubo yokuhlola isampula engahleliwe phakathi nokukhiqizwa ngobuningi. Ekukhiqizweni kwenqwaba encane, kwesinye isikhathi kuyadingeka ukuthi uhlole zonke izilinganiso zokulingisa.

Ngokuhambisana nezidingo ezicaciswe emidwebeni noma emibhalweni yokucubungula, izilinganiso zokulingisa zidinga ukuhlolwa ukuze kutholwe izilinganiso zokulawula eziyinhloko, ubukhulu obunezidingo zokunemba okuphezulu, nobukhulu obugogeke kalula futhi obungabekezeleleki. Lesi simo ngokuvamile sisetshenziswa ekuhlolweni kokulawula kobukhulu bokukhiqiza ngobuningi emugqeni wokukhiqiza.

Imikhiqizo Yokusakaza Yensimbi Yangokwezifiso

Imikhiqizo ye-Ductile Iron Casting

Isikhathi sokuthumela: Apr-14-2021