Ngokwezifiso noma insimbi engagqwali ejwayelekile 316 camlock byinqubo yokutshala imalikanye nemishini ye-CNC.

Insimbi engagqwali inokuqukethwe kwe-chromium okungenani okungu-10.5%, okuyenza imelane kakhulu nezindawo zoketshezi ezibolayo kanye ne-oxidation. Nokho, lokhu akukhona ngokuphelele. Ukulingwa kwensimbi engagqwali "ayikwazi ukugqwala" uma kusetshenziswa ezindaweni eziwuketshezi nezihwamuko ezingaphansi kuka-1200°F (650°C) kanye "nokumelana nokushisa" uma kusetshenziswa ngaphezu kwaleli zinga lokushisa. I-AISI 316 iyinsimbi engagqwali ye-austenitic esetshenziswa kabanzi ukutshala imali.

Insimbi engagqwali ye-Austenitic kufanele iphathwe ngesixazululo esiqinile ngaphambi kokusetshenziswa, ukuze kwandiswe isisombululo esiqinile semvula ehlukahlukene njenge-carbides ensimbi ibe yi-austenite matrix, kuyilapho i-homogenizing isakhiwo futhi iqeda ingcindezi, ukuze kuqinisekiswe ukumelana nokugqwala okuhle kakhulu kanye izakhiwo zemishini. Uhlelo olulungile lokwelapha isixazululo ukupholisa amanzi ngemva kokushisisa ku-1050~1150℃ (izingxenye ezincanyana nazo zingapholiswa ngomoya). Izinga lokushisa lokwelapha isixazululo lincike ezingeni le-alloying yensimbi: I-molybdenum-free noma i-low-molybdenum steel amamaki kufanele abe ngaphansi (≤1100℃), kanye namamaki ahlanganisiwe aphezulu njenge-00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, njll. kufanele abe phezulu ( 1080–1150) ℃).

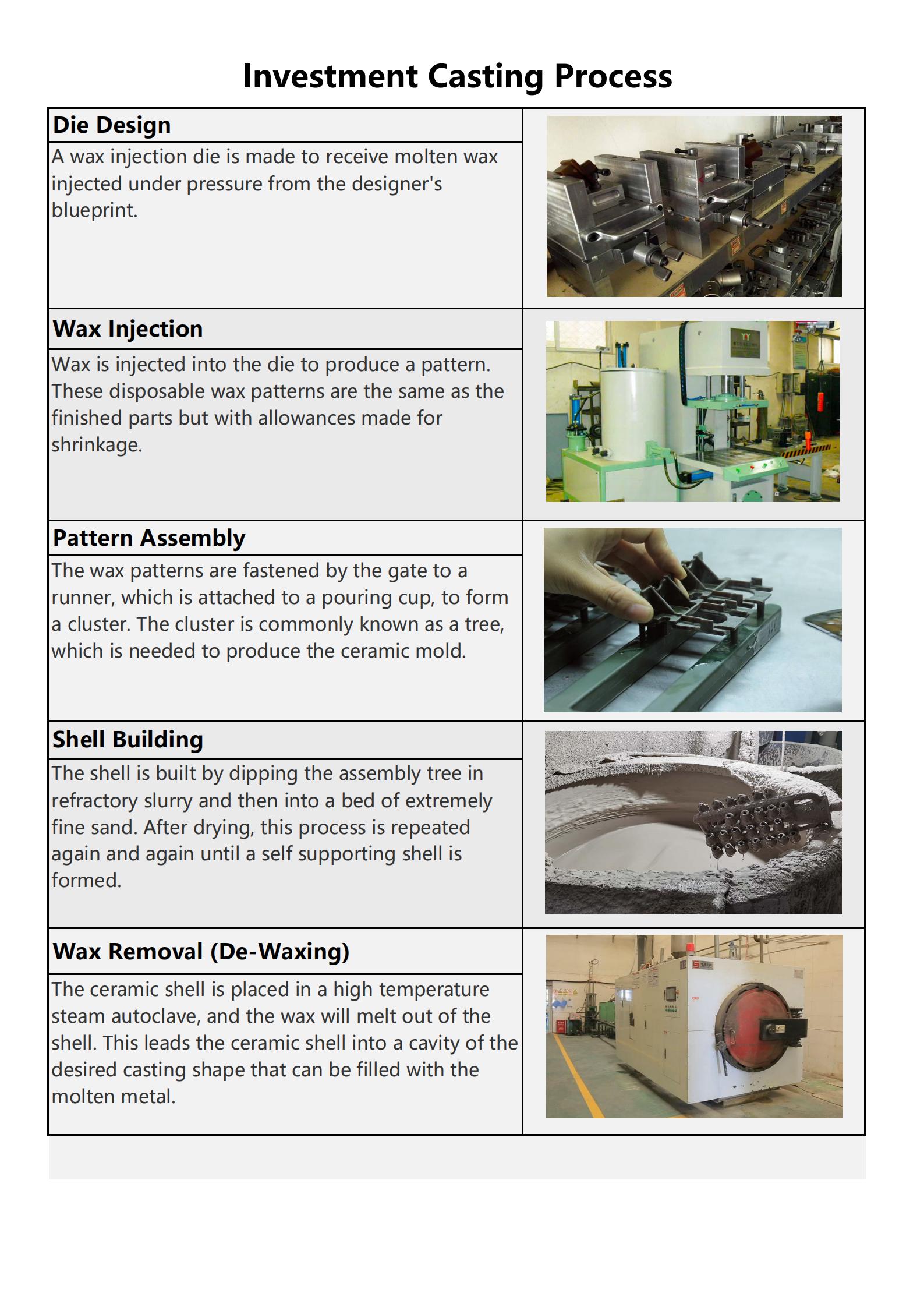

Amandla e-Investment Casting Foundry:

- • Ubukhulu Usayizi: 1,000 mm × 800 mm × 500 mm

- • I-Weight Range: 0.5 kg - 100 kg

- • Amandla onyaka: amathani ayi-2,000

- • Izinto Zebhondi Zokwakha I-Shell: I-Silica Sol, Ingilazi Yamanzi kanye nezingxube zayo.

- • Ukubekezelelana: Ngesicelo.

Izinzuzo ze-Investing Casting Components:

- - Excellent and smooth surface finish

- - Ukubekezelelana okuqinile kwe-dimensional.

- - Izimo eziyinkimbinkimbi neziyinkimbinkimbi ezinokuguquguquka komklamo

- - Ikhono lokuphonsa izindonga ezincane ngakho-ke ingxenye yokusakaza elula

- - Ukukhetha okubanzi kwezinsimbi kanye nama-alloys (ayoni futhi angeyona insimbi)

- - Uhlaka aludingeki ekwakhiweni kwesikhunta.

- - Yehlisa isidingo sokuba machining yesibili.

- - Imfucuza yezinto eziphansi.

| Izinto zokwakha zeInvestment CastingInqubo e-RMC Foundry | |||

| Isigaba | Ibanga laseShayina | Ibanga lase-US | Ibanga laseJalimane |

| I-Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| I-Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Insimbi engagqwali ye-Austenitic | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.44404, 1.4404, 9 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Imvula Iqinisa Insimbi Engagqwali | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| I-Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Insimbi Yensimbi | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Insimbi Engangeni Ukushisa | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| I-Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| I-Aluminium Ingxubevange | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | I-G-AlSi7Mg, G-Al12 |

| Ingxubevange yethusi | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| I-Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

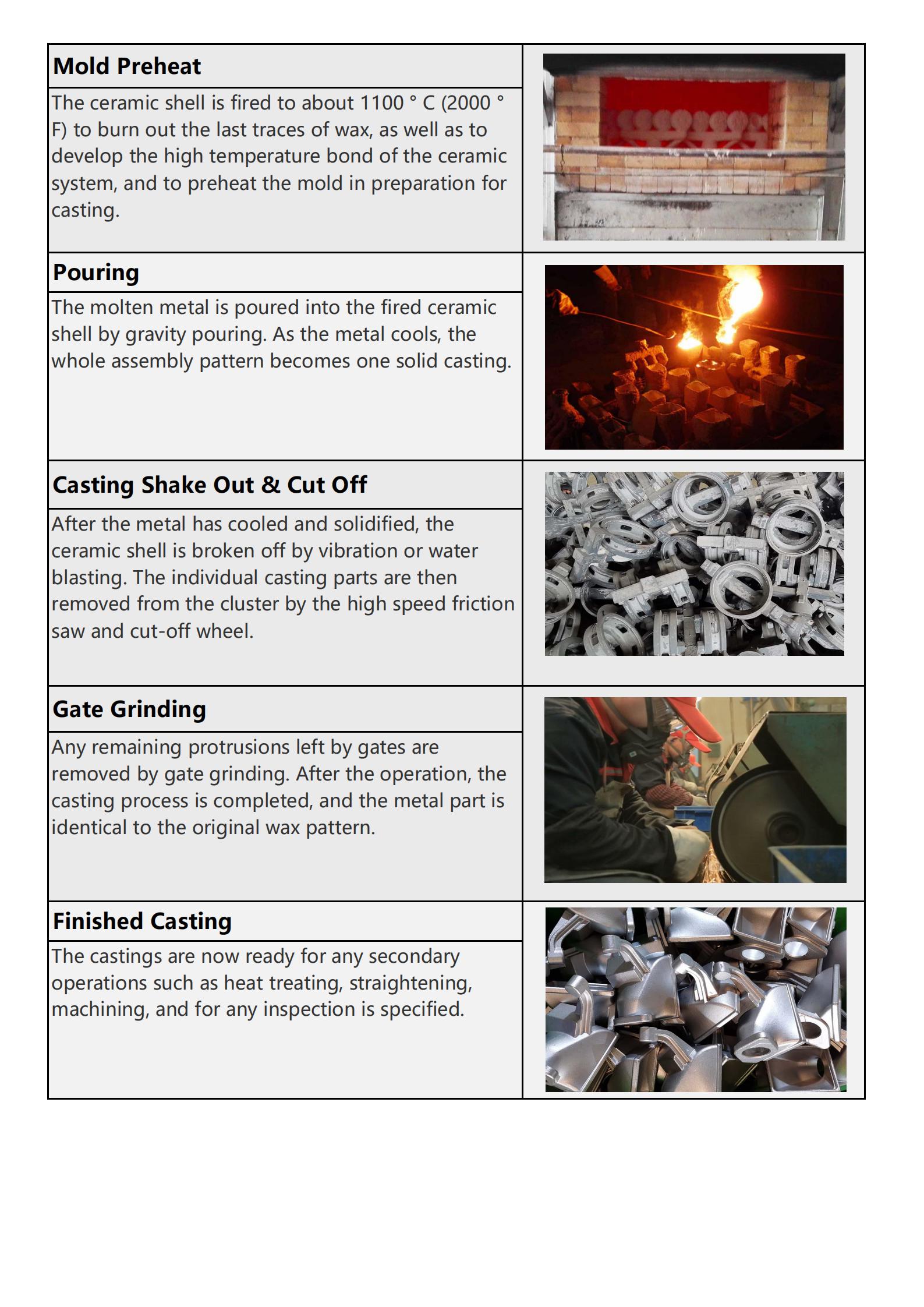

| UKUBEKEZELEKA KOKUKHISHWA KOKUTSHALWA KWEMALI | |||

| Amayintshi | Amamilimitha | ||

| Ubukhulu | Ukubekezelelana | Ubukhulu | Ukubekezelelana |

| Kufika ku-0.500 | ±.004" | Kufika ku-12.0 | ± 0.10mm |

| 0.500 kuya ku-1.000" | ±.006" | 12.0 ukuze 25.0 | ± 0.15mm |

| 1.000 kuya ku-1.500" | ±.008" | 25.0 ukuze 37.0 | ± 0.20mm |

| 1.500 kuya ku-2.000" | ±.010" | 37.0 kuye ku-50.0 | ± 0.25mm |

| 2.000 kuya ku-2.500" | ±.012" | 50.0 ukuze 62.0 | ± 0.30mm |

| 2.500 kuya ku-3.500" | ±.014" | 62.0 ukuze 87.0 | ± 0.35mm |

| 3.500 kuya ku-5.000" | ±.017" | 87.0 ukuze 125.0 | ± 0.40mm |

| 5.000 kuya ku-7.500" | ±.020" | 125.0 kuya ku-190.0 | ± 0.50mm |

| 7.500 kuya ku-10.000" | ±.022" | 190.0 ukuze 250.0 | ± 0.57mm |

| 10.000 kuya ku-12.500" | ±.025" | 250.0 ukuze 312.0 | ± 0.60mm |

| 12.500 ukuze 15.000 | ±.028" | 312.0 ukuze 375.0 | ± 0.70mm |