Idizayini ye-Riser iyisici esibalulekile senqubo yokulingisa, iqinisekisa ukuthi ukulingisa akunasici njengama-shrinkage cavities kanye ne-porosity. Izikhuphukeli, ezaziwa nangokuthi iziphakeli, zisebenza njengemithombo yensimbi encibilikisiwe ephakela ukubunjwa njengoba iqina futhi inkontileka.

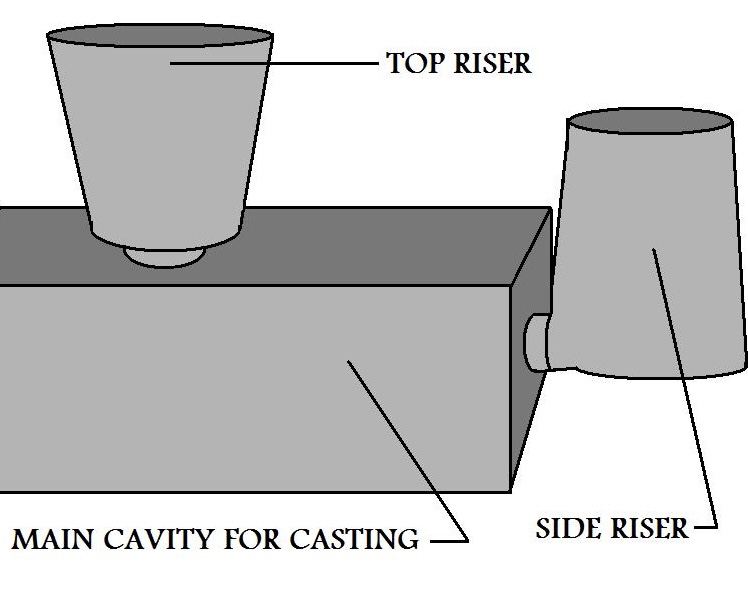

Idizayini yeRiser yokusakazwa kwensimbi

In steel utshalomali Casting, inhloso eyinhloko yokuklama kwesikhuphukeli ukuqinisekisa ukondla okwanele kwensimbi encibilikisiwe ukuze kunxeshezelwe ukuncipha kwevolumu ngesikhathi sokuqina. Insimbi ivamise ukuba namazinga aphezulu okushwabana, okwenza ukuklama kwesikhuphukeli esisebenzayo kube bucayi.

Ukwakhiwa kwensimbi, izinhlobo ezimbili eziyinhloko zokukhuphuka zisetshenziswa:izikhuphukeli ezivulekile futhiizikhuphukeli eziyizimpumputhe. Izikhuphukeli ezivulekile zivezwa emkhathini, kuyilapho izikhuphukeli eziyimpumputhe zivalelwe ngaphakathi kwesikhunta. Izikhuphukeli eziyimpumputhe zisebenza kahle kakhulu ekwehliseni ukulahlekelwa ukushisa.

Izikhuphukeli kufanele zibe sezingxenyeni ezisinda kakhulu zokulingisa lapho kungenzeka khona ukuncipha. Ubukhulu kanye nokuma kwesikhuphukeli kufanele kuklanywe ukuqinisekisa umthamo owanele wensimbi encibilikisiwe. Izikhuphukeli eziyi-cylindrical zivame ukusetshenziselwa ukukhululeka kwazo kanye nokusebenza ngempumelelo ekondleni. Imikhono evikelayo kanye nezinto ze-exothermic zivame ukusetshenziselwa ukugcina izinga lokushisa lesikhuphukeli, kuqinisekiswe ukuthi lihlala lincibilikile isikhathi eside kunokuphonsa.

Idizayini yesikhuphukeli ye-Iron Castings

Ngobai-iron investment castings, ikakhulukazi insimbi empunga kanye ne-ductile, umgomo uwukuphatha izici zokunweba ngesikhathi sokuqina. Ngokungafani nensimbi, ezinye izinhlobo zensimbi zanda phakathi nezigaba zokugcina zokuqina, zinciphisa isidingo sezikhuphukeli ezinkulu.

Izikhuphukeli eziyizimpumputhe zithandwa kakhulu ngensimbi ngenxa yokusebenza kahle kwazo. Ngensimbi ene-ductile, izikhuphukeli ezincane ngokuvamile zinganele ngenxa yokwanda kwe-graphite ngesikhathi sokuqina.

Izikhuphukeli ezincane, ezihlangene kakhulu zingasetshenziselwa ukwakhiwa kwensimbi. Umumo ungahluka kodwa kufanele unciphise indawo engaphezulu evezwe ekulahlekelweni ukushisa kuyilapho kukhulisa ukusebenza kahle kokuphakelayo. Ukugodola (izinto ezimunca ukushisa) ngezinye izikhathi zisetshenziswa ngokuhambisana nezikhuphukeli ukuze kulawulwe izinga lokupholisa kanye nokukhuthaza ukuqiniswa kwesiqondiso ngasesikhuphukeni.

.jpg)

Idizayini yesikhuphukeli ye-Non-FrorousI-alloy Castings

Ama-alloys angewona ayoni, njenge-aluminium nama-alloys ethusi, anokuziphatha okuqinile okuhlukile uma kuqhathaniswa nezinsimbi ezisansimbi. Inhloso eyinhloko ukuvimbela ukukhubazeka okufana ne-shrinkage porosity kanye nokuqinisekisa ukugcwaliswa okuphelele kwesikhunta.

Ku-castings non-ferrous, kokubili izikhuphukeli ezivulekile neziyimpumputhe zisetshenziswa, kuye ngokuthi i-alloy kanye nomklamo wokuphonsa. Izikhuphukeli ezivulekile zivame kakhulu ekubunjweni okuncane, kuyilapho izikhuphukeli ezingaboni zisetshenziselwa ukulingisa okukhulu.

Ama-alloys angeyona i-ferrous ngokuvamile adinga izikhuphukeli ukuthi zibekwe ezindaweni eziphakeme kakhulu zokusakaza ukuze kusetshenziswe amandla adonsela phansi.

Usayizi wesikhuphukeli udinga ukulandisa ngokuminyana okuphansi kanye namazinga aphezulu okushwabana kwama-alloys angewona ayoni. Izikhuphukeli ezicijile noma ezinentamo zingasiza ekwehliseni ukulahlekelwa ukushisa nasekuthuthukiseni ukusebenza kahle kokuphakela. I-insulation ibalulekile kuma-alloys angewona ayoni, njengoba ngokuvamile aqina emazingeni okushisa aphansi. Izinto ezisetshenziswayo ezishisayo kanye nemikhono evikelayo ingasiza ekugcineni ukuncibilika kwesikhuphukeli isikhathi eside.

Isikhathi sokuthumela: Dec-20-2024