I-Industrial electrocoating iyindlela yokwelapha yendawo esetshenziswa kabanzi ukuvikela i-izinsimbi zensimbikanye nemikhiqizo yemishini ye-CNC evela ekugqwaleni ngokuqedwa okuhle. Amakhasimende amaningi abuza imibuzo mayelana nokwelashwa okungaphezulu kwezinsimbi zensimbi kanyeukunemba ngomshini izingxenye. Lesi sihloko sizogxila kwinqubo yokugqoka i-electrophoretic. Ngethemba ukuthi kuzoba usizo kubo bonke ozakwethu.

I-Electrocoating iyindlela yokumboza lapho izinhlayiya ezinjenge-pigments nama-resin alenga kusixazululo se-electrophoretic ziqondiswe ukuze zifuduke futhi zibeke endaweni eyodwa yama-electrode ngokusebenzisa insimu yangaphandle kagesi. Isimiso sokumboza i-electrophoretic sasungulwa ekupheleni kweminyaka yama-1930, kodwa lobu buchwepheshe bathuthukiswa futhi bathola ukusetshenziswa kwezimboni ngemva kuka-1963. I-Electrophoretic coating iyinqubo yokwakha ewusizo kakhulu yokugqoka okusekelwe emanzini. I-Electrophoretic coating inezici zokuncibilika kwamanzi, ukungabi nobuthi, nokulawula okuzenzakalelayo okulula. Ngenxa yokuthi ilungele ukwelapha okungaphezulu kwama-workpieces asebenzayo (insimbi, izingxenye zomshini, izinsimbi, izingxenye zensimbi nezingxenye zokushisela, njll.), inqubo yokuhlanganisa i-electrophoretic isisetshenziswe kabanzi ezimbonini ezifana nezimoto, izinto zokwakha, i-hardware. , nezinto zikagesi zasendlini.

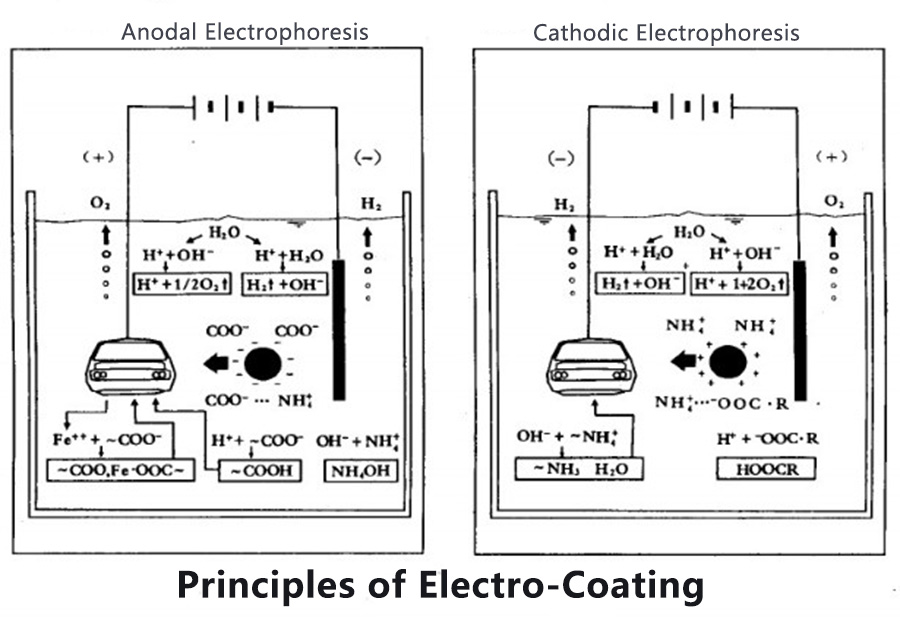

Izimiso

I-resin equkethwe ku-cathodic electrophoretic coating inamaqembu ayisisekelo, akha usawoti ngemva kokungathathi hlangothi kwe-asidi futhi ancibilike emanzini. Ngemuva kokusetshenziswa kwamandla aqondile, ama-ion ane-asidi ama-radical negative athuthela ku-anode, futhi ama-resin ion kanye nezinhlayiya ze-pigment ezisongwe ngazo zithuthela ku-cathode ngamashaji amahle futhi zifakwe ku-cathode. Lesi yisimiso esiyisisekelo se-electrophoretic coating (evame ukwaziwa ngokuthi i-plating). I-Electrophoresis coating iwukusabela kwe-electrochemical eyinkimbinkimbi kakhulu, okungenani imiphumela emine ye-electrophoresis, i-electrodeposition, i-electrolysis, kanye ne-electroosmosis zenzeka ngesikhathi esisodwa.

I-Electrophoresis

Ngemuva kokuthi i-anode ne-cathode kusisombululo se-colloidal kuvuliwe, izinhlayiya ze-colloidal zithuthela ohlangothini lwe-cathode (noma i-anode) ngaphansi kwesenzo senkambu kagesi, ebizwa ngokuthi i-electrophoresis. I-substance ku-colloidal solution ayikho esimweni sama-molecule nama-ion, kodwa i-solute ehlakazekile oketshezini. Into inkulu futhi ngeke ihle ibe sesimweni sokuhlakazeka.

I-Electrodeposition

Isenzakalo semvula eqinile evela oketshezini ibizwa ngokuthi i-agglomeration (i-agglomeration, deposition), evame ukukhiqizwa lapho kupholisa noma kugxiliswe isixazululo, futhi ukunamathela kwe-electrophoretic kuncike kugesi. Ku-cathodic electrophoretic coating, izinhlayiya ezine-positive charge ziyahlangana ku-cathode, kanye nezinhlayiya ezishajelwe kabi (okungukuthi ama-ion) ahlanganisa ku-anode. Lapho izinhlayiya ze-colloidal ezifakwe kahle (i-resin ne-pigment) zifinyelela ku-cathode (i-substrate) Ngemva kwendawo engaphezulu (ungqimba olubonakalayo olune-alkaline kakhulu), ama-electron atholakala futhi asabelane nama-ion hydroxide ukuze abe izinto ezingancibiliki emanzini, ezifakwa ku-cathode ( i-workpiece ependiwe).

I-Electrolysis

Esixazululweni esine-ionic conductivity, i-anode ne-cathode ixhunywe kumanje oqondile, ama-anion akhangwa ku-anode, futhi ama-cation akhangwa ku-cathode, futhi ukusabela kwamakhemikhali kwenzeka. I-anode ikhiqiza ukuncibilika kwensimbi kanye ne-electrolytic oxidation ukuze ikhiqize umoya-mpilo, i-chlorine, njll. I-anode iyi-electrode engakhiqiza ukusabela kwe-oxidation. Insimbi iyana ku-cathode futhi i-H+ yehliswa ngogesi ibe yi-hydrogen.

I-Electroosmosis

Ngemuva kokuthi iziphetho ezimbili (i-cathode ne-anode) yezixazululo ezinezingxube ezihlukene ezihlukaniswe ulwelwesi lwe-semipermeable zinikezwa amandla, isenzakalo sokuthi isixazululo sokugxilwa okuphansi sithuthela ohlangothini oluphezulu lokugxila lubizwa ngokuthi i-electroosmosis. Ifilimu yokumboza esanda kufakwa ebusweni bento eboshiwe iyifilimu ekwazi ukungena kancane. Ngaphansi kwesenzo esiqhubekayo senkambu kagesi, amanzi aqukethwe ku-dialysis yefilimu egcobayo aphuma kufilimu futhi athuthele kubhavu ukuze akhiphe amanzi efilimu. Lokhu kuyi-electroosmosis. I-Electroosmosis iphendula ifilimu yokumboza i-hydrophilic ibe ifilimu yokuhlanganisa i-hydrophobic, futhi ukuphelelwa amanzi emzimbeni kwenza ifilimu yokumboza iminyene. Upende omanzi ngemva kokubhukuda ngopende omuhle we-electro-osmosis electrophoretic ungathinteka futhi unganamatheli. Ungakwazi ukugeza uketshezi lokugeza unamathele ifilimu kapende emanzi ngamanzi.

Izici ze-Electrocoating

Ifilimu yepende ye-Electrophoretic inezinzuzo zokugcwala, ukufana, ukucaba kanye nokugqoka okubushelelezi. Ubulukhuni, ukunamathela, ukumelana nokugqwala, ukusebenza komthelela, kanye nokungeneka kwefilimu kapende we-electrophoretic kungcono kakhulu kunezinye izinqubo zokumboza.

(1) Kusetshenziswa upende oncibilika emanzini, amanzi asetshenziswa njengendlela encibilikayo, esindisa izincibilikisi eziningi eziphilayo, enciphisa kakhulu ukungcoliswa komoya kanye nezingozi zemvelo, iphephile futhi ihlanzekile, futhi igwema ingozi ecashile yomlilo;

(2) Ukusebenza kahle kokudweba kuphezulu, ukulahlekelwa upende kuncane, futhi izinga lokusebenzisa upende lingafinyelela ku-90% kuya ku-95%;

(3) Ugqinsi lwefilimu enamathelayo luyiyunifomu, ukunamathela kuqinile, nekhwalithi yokumboza yinhle. Ingxenye ngayinye ye-workpiece, njengesendlalelo sangaphakathi, ama-depressions, ama-welds, njll., ingathola ifilimu yokugqoka iyunifomu futhi ebushelelezi, exazulula inkinga yezinye izindlela zokumboza ze-workpieces eziyinkimbinkimbi. Inkinga yokudweba;

(4) Ukusebenza kahle kokukhiqiza kuphezulu, futhi ukwakhiwa kungathola ukukhiqiza okuzenzakalelayo nokuqhubekayo, okuthuthukisa kakhulu ukusebenza kahle kwabasebenzi;

(5) Izinto ezisetshenziswayo ziyinkimbinkimbi, izindleko zokutshala izimali ziphakeme, ukusetshenziswa kwamandla kukhulu, izinga lokushisa elidingekayo ekomisweni nasekuphulukisweni liphezulu, ukuphathwa kopende nokudweba kuyinkimbinkimbi, izimo zokwakha ziqinile, futhi ukugezwa kwamanzi angcolile kuyadingeka. ;

(6) Kungasetshenziswa upende oncibilika emanzini kuphela, futhi umbala awukwazi ukushintshwa phakathi nenqubo yokumboza. Ukuzinza kopende akulula ukulawula ngemva kokugcinwa isikhathi eside.

(7) Izinto zokumboza i-electrophoretic ziyinkimbinkimbi futhi okuqukethwe kobuchwepheshe kuphezulu, okufanele ukukhiqizwa kombala ongaguquki.

Imikhawulo ye-Electrocoating

(1) Ifanele kuphela ukumbozwa kwe-primer yama-conductive substrates njengezingxenye zomshini zezinsimbi ezisansimbi nezinsimbi ezingenayo insimbi. Izinto ezingezona e-conductive ezifana nokhuni, ipulasitiki, indwangu, njll. azikwazi ukumbozwa ngale ndlela.

(2) Inqubo yokugqoka i-Electrophoretic ayifanele izinto ezimboziwe ezakhiwe ngezinsimbi eziningi, uma izici ze-electrophoresis zihlukile.

(3) Inqubo yokugqoka i-Electrophoretic ayikwazi ukusetshenziselwa izinto eziboshwe ezingakwazi ukumelana nokushisa okuphezulu.

(4) I-Electrophoretic coating ayifanele ukumbozwa ngezidingo ezilinganiselwe kumbala. I-Electrophoretic coating yemibala ehlukene idinga ukupeyintwa emithonjeni ehlukene.

(5) Ukufakwa kwe-electrophoretic akunconyelwe ekukhiqizeni inqwaba encane (isikhathi sokuvuselela ukugeza singaphezu kwezinyanga ezingu-6), ngoba ijubane lokuvuselela lokugeza lihamba kancane, inhlaka ebhavini iyaguga futhi okuqukethwe kwe-solvent kuyashintsha. kakhulu. Ibhavu alizinzile.

Izinyathelo ze-Electrocoating

(1) Ukuze kufakwe i-electrophoretic yezindawo ezivamile zensimbi, ukugeleza kwenqubo yilena: ukuhlanza kuqala → ukwehlisa → ukugeza amanzi → ukususwa kokugqwala → ukugeza amanzi → ukungathathi hlangothi → ukugeza amanzi → phosphating → ukugeza amanzi → passivation → i-electrophoretic coating → ukuhlanza ithangi eliphezulu → ukugeza amanzi nge-ultrafiltration → ukomisa → okungaxhunyiwe ku-inthanethi.

(2) I-substrate ne-pretreatment yento eboshiwe inethonya elikhulu kwifilimu yokugqoka i-electrophoretic. Izinsimbi ezisansimbi ngokuvamile zichithwa ukuqhunyiswa kwesihlabathi noma ukuqhunyiswa kwesibhamu, intambo kakotini isetshenziselwa ukususa uthuli oluntantayo phezu kwendawo yokusebenza, futhi i-sandpaper isetshenziselwa ukususa izinsalela zensimbi nezinye izibi. Ingaphezulu lensimbi liphathwa nge-degreasing kanye nokususwa kokugqwala. Lapho izidingo ezingaphezulu ziphezulu kakhulu, i-phosphating ne-passivation surface treatment iyadingeka. Izinto zokusebenza zensimbi ezisansimbi kufanele zenziwe i-phosphated ngaphambi kwe-anodic electrophoresis, ngaphandle kwalokho ukumelana nokugqwala kwefilimu kapende kuzoba kubi. Ekwelashweni kwe-phosphating, ifilimu ye-zinc kasawoti phosphating ngokuvamile ikhethwa, enogqinsi olungaba ngu-1 kuya ku-2 μm, futhi ifilimu ye-phosphate iyadingeka ukuze ibe namakristalu amahle futhi afanayo.

(3) Kuhlelo lokuhlunga, ukuhlunga okuyinhloko kuvame ukwamukelwa, futhi isihlungi siyisakhiwo sesikhwama semeshi. Upende we-electrophoretic uthuthwa uyiswe kusihlungi ngepompo eqondile ukuze uhlunge. Uma kucatshangelwa umjikelezo ophelele wokushintsha kanye nekhwalithi yefilimu kapende, isikhwama sokuhlunga esinosayizi wembotshana ongu-50μm singcono kakhulu. Ayikwazi ukuhlangabezana nezidingo zekhwalithi zefilimu yepende, kodwa futhi ixazulule inkinga yokuvala isikhwama sokuhlunga.

(4) Ubukhulu besistimu yokujikeleza ye-electrophoretic coating ithinta ngokuqondile ukuzinza kokugeza kanye nekhwalithi yefilimu kapende. Ukwandisa umthamo wokujikeleza kunciphisa imvula namabhamuza oketshezi lokugeza; noma kunjalo, ukuguga koketshezi lokugeza kuyashesha, ukusetshenziswa kwamandla kuyanda, futhi ukuzinza koketshezi lokugeza kuba kubi kakhulu. Kuhle ukulawula izikhathi zomjikelezo we-tank liquid izikhathi ezingu-6-8 / h, ezingagcini nje ngokuqinisekisa ikhwalithi yefilimu yokupenda, kodwa futhi iqinisekisa ukusebenza okuzinzile kwe-tank liquid.

(5) Njengoba isikhathi sokukhiqiza sikhula, i-impedance ye-anode diaphragm izokhula futhi i-voltage esebenzayo yokusebenza izokwehla. Ngakho-ke, ekukhiqizeni, i-voltage yokusebenza kwamandla kagesi kufanele ikhuliswe kancane kancane ngokuya ngokulahleka kukagesi ukuze kunxeshezelwe ukwehla kwamandla kagesi we-anode diaphragm.

(6) Uhlelo lwe-ultrafiltration lulawula ukuhlangana kwama-ion angcolile alethwe isiqeshana sokusebenza ukuze kuqinisekiswe ikhwalithi yokunamathela. Ekusebenzeni kwalolu hlelo, kufanele kuqashelwe ukuthi uma uhlelo selusebenza, kufanele lusebenze ngokuqhubekayo futhi lunqatshelwe ngokuphelele ukuthi lusebenze ngezikhathi ezithile ukuvimbela ulwelwesi lwe-ultrafiltration ukuthi lome. I-resin eyomile kanye ne-pigment inamathela kulwelwesi lwe-ultrafiltration futhi ayikwazi ukuhlanzwa kahle, okuzophazamisa kakhulu ukungena kwamanzi kanye nempilo yesevisi ye-ultrafiltration membrane. Izinga lokuphuma kwamanzi le-membrane ye-ultrafiltration libonisa ukuthambekela kokwehla ngesikhathi sokusebenza. Kufanele ihlanzwe kanye ngezinsuku ezingama-30-40 zomsebenzi oqhubekayo ukuze kuqinisekiswe amanzi acwengezelayo adingekayo ukuze kukhishwe i-ultrafiltration nokugeza.

(7) Indlela yokugqoka i-electrophoretic ifaneleka inqubo yokukhiqiza inombolo enkulu yemigqa yokuhlanganisa. Umjikelezo wokuvuselela okugeza kwe-electrophoresis kufanele ube phakathi nezinyanga ezi-3. Ukuphathwa kwesayensi yokugeza kubaluleke kakhulu. Imingcele ehlukahlukene yokugeza ihlolwe njalo, futhi ukugeza kuyalungiswa futhi kushintshwe ngokuvumelana nemiphumela yokuhlolwa. Ngokuvamile, imingcele yesisombululo sokugeza ilinganiswa ngokuvama okulandelayo: inani le-pH, okuqukethwe okuqinile kanye nokusebenza kwesisombululo se-electrophoresis, isisombululo se-ultrafiltration kanye nesisombululo sokuhlanza i-ultrafiltration, i-anion (anode) isisombululo se-polar, i-lotion ejikelezayo, nesisombululo sokuhlanza i-deionization kanye. usuku; Isisekelo sesilinganiso, okuqukethwe kwe-organic solvent, nokuhlolwa kwethangi elincane laselabhorethri kabili ngeviki.

(8) Ukuze kulawulwe ikhwalithi yefilimu kapende, ukufana nokujiya kwefilimu kapende kufanele kuhlolwe njalo, futhi ukubukeka akufanele kube nezimbobo, ukugoqa, ikhasi lewolintshi, imibimbi, njll. Njalo hlola umzimba kanye namakhemikhali. izinkomba ezifana nokunamathela kanye nokumelana nokugqwala kwefilimu yokugqoka. Umjikelezo wokuhlola uhambisana nezindinganiso zokuhlola zomkhiqizi, futhi ngokuvamile iqoqo ngalinye lidinga ukuhlolwa.

Ukwelashwa Kwangaphandle Ngaphambi Kwe-Electrophoresis

Ukwelashwa okungaphezulu kwe-workpiece ngaphambi kokumboza kuyingxenye ebalulekile ye-electrophoretic coating, ikakhulukazi ehilela ukwehlisa, ukususwa kokugqwala, ukumisa ubuso, i-phosphating nezinye izinqubo. Ikhwalithi yokwelashwa kwayo ayithinti kuphela ukubonakala kwefilimu, inciphisa ukusebenza kwe-anti-corrosion, kodwa futhi ibhubhisa ukuzinza kwesisombululo sepende. Ngakho-ke, ebusweni bomsebenzi ngaphambi kokudweba, kuyadingeka ukuthi kungabi namabala amafutha, amamaki okugqwala, amakhemikhali angaphambi kokwelashwa kanye ne-phosphating sedimentation, njll., futhi ifilimu ye-phosphating inamakristalu aminyene futhi afanayo. Mayelana nezinqubo ezihlukahlukene zokwelashwa kwangaphambili, ngeke sixoxe ngazo ngazinye, kodwa sizobeka amaphuzu ambalwa okunaka:

I-1) Uma i-degreasing kanye nokugqwala kungahlanzekile, ngeke kuthinte kuphela ukwakheka kwefilimu ye-phosphating, kodwa futhi kuthinte amandla okubopha, ukusebenza kokuhlobisa kanye nokumelana nokugqwala kwengubo. Ifilimu kapende ijwayele ukuncipha kanye namaphinifa.

I-2) I-Phosphating: Inhloso ukuthuthukisa ikhono lokunamathela kanye ne-anti-corrosion yefilimu ye-electrophoretic. Iqhaza layo limi kanje:

(1) Ngenxa yemiphumela engokomzimba namakhemikhali, ukunamathela kwefilimu ehlanganisa izinto eziphilayo ku-substrate kuyathuthukiswa.

(2) Ifilimu ye-phosphating iphendula ingaphezulu lensimbi isuke ku-conductor enhle iye ku-conductor ompofu, ngaleyo ndlela ivimbele ukwakheka kwamabhethri amancane endaweni yensimbi, ivimbele ngempumelelo ukugqwala kwento enamathelayo, futhi yandise ukumelana nokugqwala nokumelana namanzi enamathela. Ukwengeza, kuphela ngesisekelo se-bottom kanye ne-degreasing, ifilimu eyanelisayo ye-phosphating ingakhiwa endaweni ehlanzekile, efanayo, nengenawo amafutha. Kusukela kulesi sici, ifilimu ye-phosphating ngokwayo iyindlela yokuzihlola enembile futhi enokwethenjelwa emphumeleni wenqubo yokwelashwa kwangaphambili.

I-3) Ukugeza: Ikhwalithi yokugeza esigabeni ngasinye sokwelashwa izoba nomthelela omkhulu kwikhwalithi yawo wonke ama-pretreatment kanye nefilimu yopende. Ukuhlanzwa kokugcina kwamanzi okwenziwe nge-deionized ngaphambi kokupenda, qiniseka ukuthi ukugeleza okuconsayo kwento eboshiwe akungaphezu kuka-30μs/cm. Ukuhlanza akuhlanzekile, njenge-workpiece:

(1) I-asidi eyinsalela, uketshezi lwamakhemikhali e-phosphating, ukugeleza kwe-resin oketshezini lukapende, kanye nokuwohloka kokuzinza;

(2) Izinsalela zakwamanye amazwe (amabala kawoyela, uthuli), izimbobo ezinciphayo, izinhlayiya nezinye izici efilimini kapende;

(3) Ama-electrolyte asele kanye nosawoti kuholela ekwandeni kokusabela kwe-electrolysis futhi kukhiqize amaphinikhodi nezinye izifo.

Isikhathi sokuthumela: Apr-17-2021