Ukwelashwa kokushisa kokusakazwa kwensimbi kusekelwe kumdwebo wesigaba se-Fe-Fe3C ukuze kulawulwe i-microstructure yokusakazwa kwensimbi ukuze kuzuzwe ukusebenza okudingekayo. Ukwelashwa kokushisa kungenye yezinqubo ezibalulekile ekukhiqizeni ama-castings ensimbi. Ikhwalithi kanye nomphumela wokwelashwa kokushisa kuhlobene ngokuqondile nokusebenza kokugcina kwensimbi yensimbi.

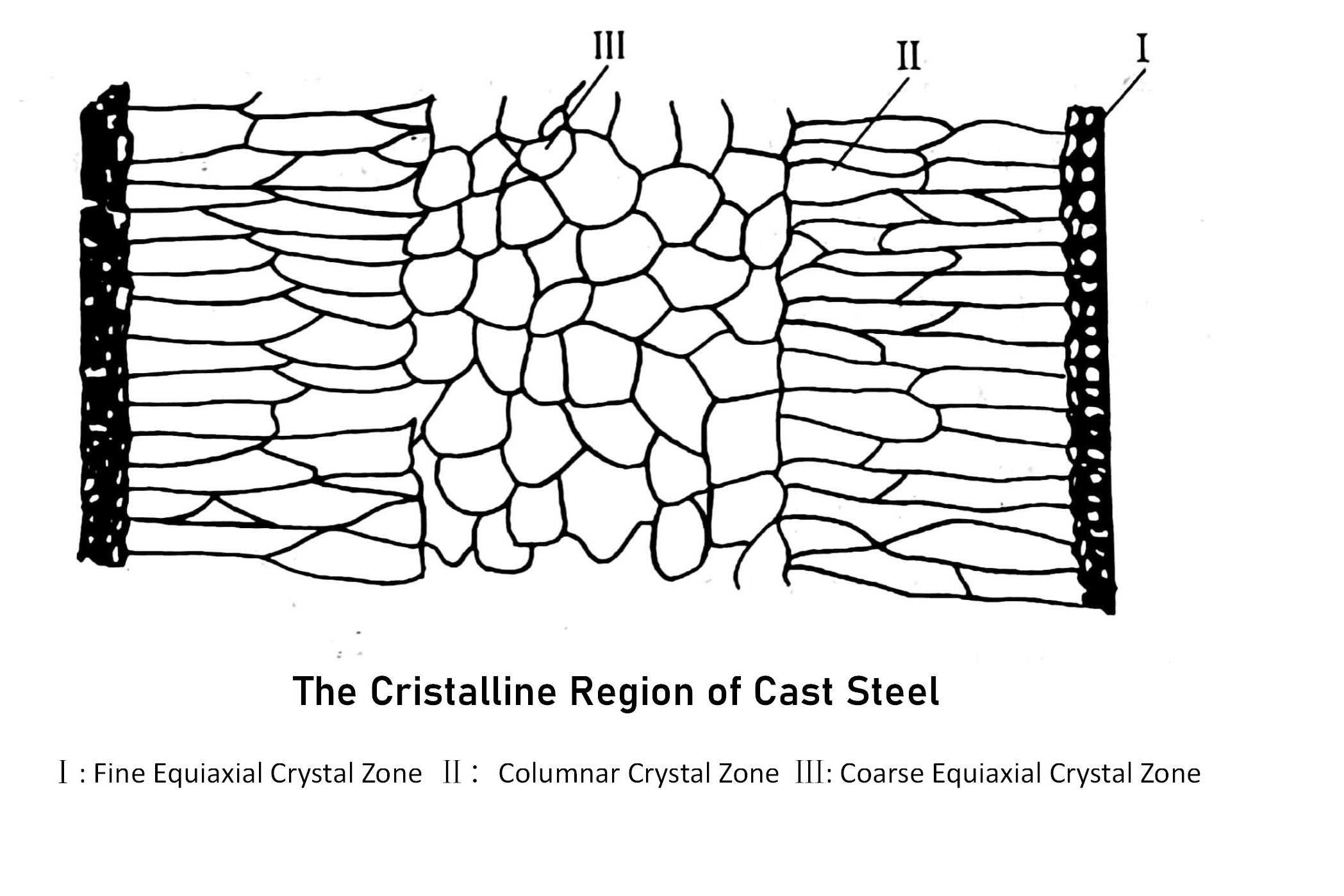

Isakhiwo se-as-cast sokusakazwa kwensimbi sincike ekwakhekeni kwamakhemikhali kanye nenqubo yokuqinisa. Ngokuvamile, kukhona ukuhlukaniswa okubucayi kwe-dendrite, ukwakheka okungalingani kakhulu kanye nezinhlamvu ezimahhadla. Ngakho-ke, ukulingwa kwensimbi ngokuvamile kudinga ukuphathwa ngokushisa ukuze kuqedwe noma kuncishiswe umthelela wezinkinga ezingenhla, ukuze kuthuthukiswe izakhiwo zemishini zokusakazwa kwensimbi. Ngaphezu kwalokho, ngenxa yomehluko wesakhiwo nokuqina kodonga lwezinsimbi zensimbi, izingxenye ezihlukahlukene zokubunjwa okufanayo zinezinhlobo ezahlukene zenhlangano futhi zenza ingcindezi enkulu eyinsalela yangaphakathi. Ngakho-ke, izinsimbi zensimbi (ikakhulukazi i-alloy steel castings) kufanele zilethwe esimweni esiphethwe ukushisa.

1. Izici Zokwelashwa Kokushisa Kokusakaza Kwensimbi

I-1) Esakhiweni se-as-cast of castings yensimbi, kuvame ukuba nama-dendrites amaholo kanye nokuhlukaniswa. Ngesikhathi sokwelashwa kokushisa, isikhathi sokushisa kufanele sibe phezulu kancane kunezingxenye zensimbi zokubumba zokubunjwa okufanayo. Ngesikhathi esifanayo, isikhathi sokubamba se-austenitization sidinga ukunwetshwa ngendlela efanele.

I-2) Ngenxa yokuhlukaniswa okunzima kwesakhiwo se-as-cast kwezinye izinsimbi zensimbi ye-alloy, ukuze kuqedwe ithonya layo ezintweni zokugcina ze-castings, izinyathelo kufanele zithathwe ukuze ku-homogenize ngesikhathi sokwelashwa kokushisa.

I-3) Ukuze uthole ukukhishwa kwensimbi okunobumo obuyinkimbinkimbi kanye nomehluko omkhulu wokuqina odongeni, imiphumela ye-cross-sectional kanye nezici zokucindezeleka kokuphonsa kufanele kucatshangelwe ngesikhathi sokwelashwa kokushisa.

I-4) Uma ukwelashwa kokushisa kwenziwa kuma-castings ensimbi, kufanele kube okunengqondo ngokusekelwe ezicini zayo zesakhiwo futhi uzame ukugwema ukuguqulwa kwe-castings.

2. Izici Eziyinhloko Zenqubo Yokwelashwa Kokushisa Kwezinsimbi Zensimbi

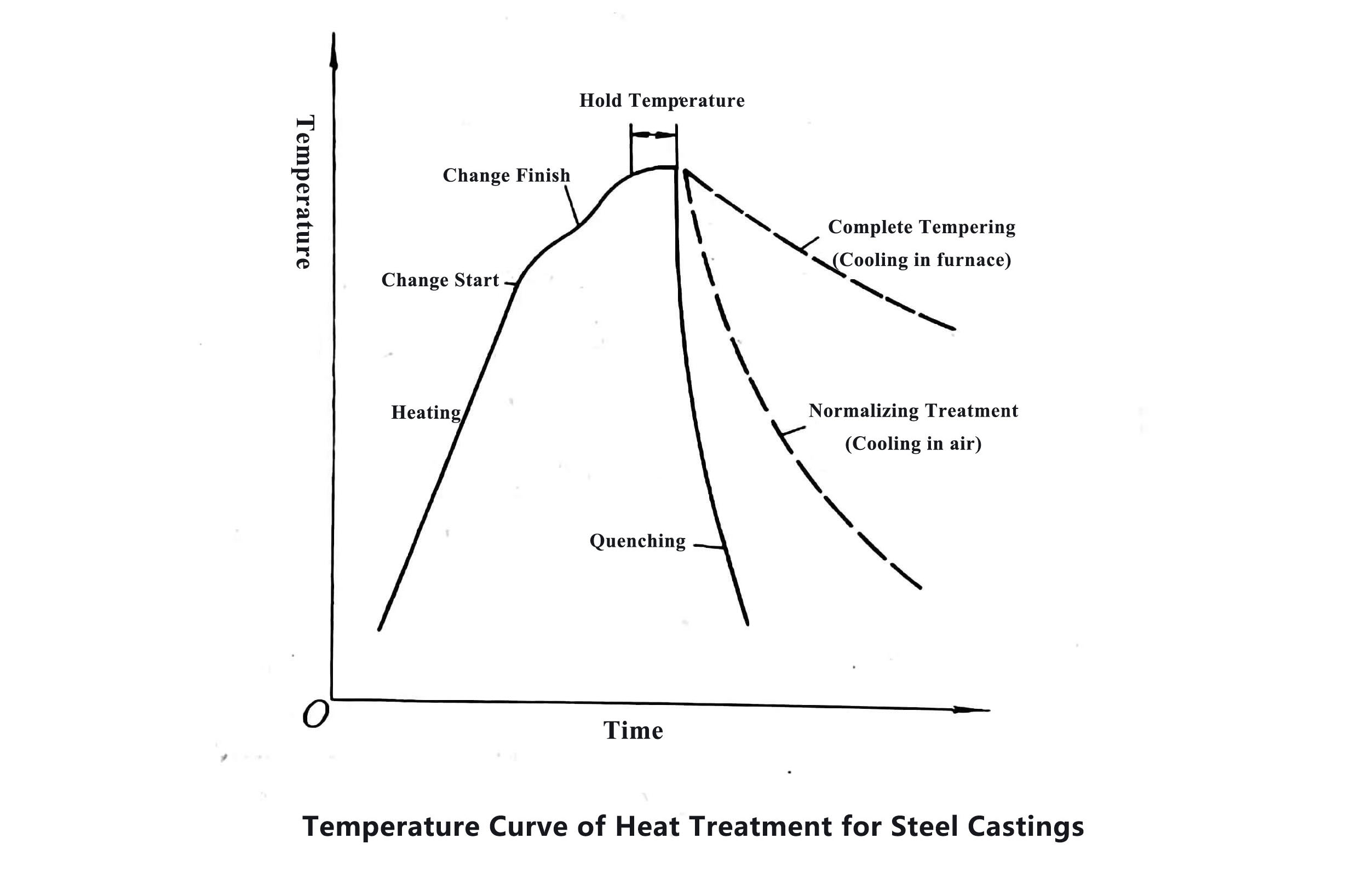

Ukwelashwa kokushisa kokusakazwa kwensimbi kunezigaba ezintathu: ukushisa, ukugcinwa kokushisa, nokupholisa. Ukunqunywa kwamapharamitha wenqubo kufanele kusekelwe enjongweni yokuqinisekisa ikhwalithi yomkhiqizo kanye nezindleko zokonga.

1) Ukushisisa

Ukushisa kuyinqubo edla amandla kakhulu enqubo yokwelapha ukushisa. Imingcele yezobuchwepheshe eyinhloko yenqubo yokushisa ukukhetha indlela yokushisa efanele, isivinini sokushisa kanye nendlela yokushaja.

(1) Indlela yokushisisa. Izindlela zokushisa zensimbi ngokuyinhloko zihlanganisa ukufudumeza okukhazimulayo, ukushisa okugeza okusawoti kanye nokufudumala kwe-induction. Isimiso sokukhetha indlela yokushisa iyashesha futhi ifana, kulula ukuyilawula, ukusebenza kahle okuphezulu kanye nezindleko eziphansi. Lapho ushisisa, i-foundry ngokuvamile icabangela usayizi wesakhiwo, ukwakheka kwamakhemikhali, inqubo yokwelapha ukushisa kanye nezidingo zekhwalithi zokubunjwa.

(2) Isivinini sokushisa. Ukuze uthole ukukhishwa kwensimbi okujwayelekile, isivinini sokushisa singase singanqunyelwe, futhi amandla aphezulu esithandweni asetshenziselwa ukushisa. Ukusetshenziswa kokushaja kwesithando somlilo esishisayo kunganciphisa kakhulu isikhathi sokushisa nomjikelezo wokukhiqiza. Eqinisweni, ngaphansi kwesimo sokushisa okusheshayo, akukho hysteresis yokushisa ecacile phakathi kobuso be-casting kanye nomgogodla. Ukushisisa kancane kuzoholela ekwehliseni ukusebenza kahle kokukhiqiza, ukwanda kokusetshenziswa kwamandla, kanye ne-oxidation engathi sína kanye nokususwa kwe-carburization endaweni yokusakaza. Kodwa-ke, kwamanye ama-castings anezimo eziyinkimbinkimbi nezakhiwo, ubukhulu bodonga olukhulu, nokucindezeleka okukhulu kokushisa ngesikhathi sokushisa, isivinini sokushisa kufanele silawulwe. Ngokuvamile, izinga lokushisa eliphansi kanye nokushisa okunensayo (ngaphansi kuka-600 °C) noma ukuhlala ekushiseni okuphansi noma okuphakathi kungasetshenziswa, bese ukufudumeza ngokushesha kungasetshenziswa ezindaweni zokushisa okuphezulu.

(3) Indlela yokulayisha. Isimiso sokuthi ama-castings ensimbi kufanele abekwe esithandweni somlilo ukusebenzisa ngokugcwele indawo ephumelelayo, ukuqinisekisa ukushisa okufanayo nokubeka ama-castings ukuze aguqulwe.

2) I-Insulation

Izinga lokushisa lokubamba le-austenitization ye-castings yensimbi kufanele likhethwe ngokuvumelana nokwakheka kwamakhemikhali ensimbi ekhonjiwe kanye nezakhiwo ezidingekayo. Izinga lokushisa lokubamba ngokuvamile liphakeme kancane (cishe u-20 °C) kunezingxenye zensimbi zokubumba zento efanayo. Ukuze kukhishwe insimbi ye-eutectoid, kufanele kuqinisekiswe ukuthi i-carbides ingafakwa ngokushesha ku-austenite, nokuthi i-austenite ingakwazi ukugcina okusanhlamvu okuhle.

Izici ezimbili okufanele zicatshangelwe ngesikhathi sokugcina ukushisa kwensimbi yensimbi: into yokuqala ukwenza izinga lokushisa lendawo yokuphonsa kanye nomfaniswano oyinhloko, futhi isici sesibili ukuqinisekisa ukufana kwesakhiwo. Ngakho-ke, isikhathi sokubamba ngokuyinhloko sincike ekuziphatheni okushisayo kwe-casting, ubukhulu bodonga besigaba kanye nezakhi ze-alloy. Ngokuvamile, ukukhishwa kwensimbi ye-alloy kudinga isikhathi eside sokubamba kune-carbon steel castings. Ubukhulu bodonga bokubunjwa ngokuvamile buyisisekelo esiyinhloko sokubala isikhathi sokubamba. Ngesikhathi sokubamba sokwelashwa kokushisisa nokwelashwa kokuguga, izici ezifana nenjongo yokwelashwa kokushisa, izinga lokushisa lokubamba kanye nezinga lokusabalalisa izinto kufanele kucatshangelwe.

3) Ukupholisa

Ama-castings ensimbi angapholiswa ngesivinini esihlukile ngemva kokugcinwa kokushisa, ukuze aqedele ukuguqulwa kwe-metallographic, athole isakhiwo esidingekayo se-metallographic futhi afinyelele izinkomba zokusebenza ezicacisiwe. Ngokuvamile, ukwandisa izinga lokupholisa kungasiza ekutholeni isakhiwo esihle futhi kucwengisiswe okusanhlamvu, ngaleyo ndlela kuthuthukiswe izakhiwo zemishini zokuphonsa. Kodwa-ke, uma izinga lokupholisa lishesha kakhulu, kulula ukubangela ingcindezi enkulu ekubumbeni. Lokhu kungase kubangele ukuwohloka noma ukuqhekeka kwama-castings anezakhiwo eziyinkimbinkimbi.

Indawo yokupholisa yokwelapha ukushisa kwensimbi ngokuvamile ihlanganisa umoya, uwoyela, amanzi, amanzi anosawoti kanye nosawoti oncibilikisiwe.

3. Indlela Yokwelapha Yokushisa Yezinsimbi Zensimbi

Ngokwezindlela ezihlukene zokushisisa, ukubamba isikhathi nezimo zokupholisa, izindlela zokwelapha ukushisa kwezinsimbi zensimbi ngokuyinhloko zihlanganisa ukuthungathwa, ukujwayela, ukucisha, ukushisa, ukwelashwa kwesixazululo, ukuqina kwemvula, ukwelashwa kokunciphisa ukucindezeleka kanye nokwelashwa kokususwa kwe-hydrogen.

1) Ukuhlobisa.

I-Annealing iwukushisa insimbi isakhiwo sayo sichezuka esimweni sokulingana siye ezingeni elithile lokushisa elinqunywe kusengaphambili inqubo, bese siyipholisa kancane ngemva kokugcina ukushisa (imvamisa ukupholisa ngesithando somlilo noma ukugqitshwa ngomcako) ukuze kutholwe inqubo yokwelapha ukushisa eduze nendawo. isimo sokulingana sesakhiwo. Ngokusho kokwakheka kwensimbi kanye nenjongo kanye nezidingo zokuhushula, ukuhunyushwa kungahlukaniswa kube ukujula okuphelele, ukuhunyushwa kwe-isothermal, i-spheroidizing annealing, i-recrystallization annealing, i-annealing yokunciphisa ingcindezi nokunye.

(1) Qedela Ukugcwalisa. Inqubo evamile yokuhlanganisa i-annealing ephelele yile: ukushisa insimbi yokusakazwa ku-20 °C-30 °C ngaphezu kwe-Ac3, ukuyibamba isikhathi esithile, ukuze isakhiwo esisensimbi siguqulwe ngokuphelele sibe i-austenite, bese sipholisa kancane (imvamisa). ukupholisa ngesithando somlilo) ku-500 ℃- 600 ℃, futhi ekugcineni kuphole emoyeni. Okubizwa ngokuthi okuphelele kusho ukuthi isakhiwo esiphelele se-austenite sitholakala lapho sishiswa.

Inhloso ye-annealing ephelele ikakhulukazi ihlanganisa: eyokuqala ukuthuthukisa isakhiwo esimahhadlahhadla futhi esingalingani esibangelwa ukusebenza okushisayo; okwesibili ukunciphisa ubulukhuni bensimbi ye-carbon steel kanye ne-alloy steel castings ngaphezu kwekhabhoni ephakathi, ngaleyo ndlela kuthuthukiswe ukusebenza kwabo kokusika (ngokujwayelekile, Lapho ubulukhuni be-workpiece buphakathi kuka-170 HBW-230 HBW, kulula ukusika. Uma ubulukhuni iphakeme noma iphansi kunalolu hlu, izokwenza ukusika kube nzima); okwesithathu ukuqeda ukucindezeleka kwangaphakathi kokuphonswa kwensimbi.

Ububanzi bokusetshenziswa kokufakwa okuphelele. I-annealing egcwele ilungele ikakhulukazi i-carbon steel ne-alloy steel castings enokwakheka kwe-hypoeutectoid enokuqukethwe kwekhabhoni kusuka ku-0.25% kuya ku-0.77%. Insimbi ye-Hypereutectoid akufanele ikhishwe ngokugcwele, ngoba lapho insimbi ye-hypereutectoid ishiselwa ngaphezu kwe-Accm futhi ipholile kancane, i-cementite yesibili izokwehla eduze komngcele wokusanhlamvu we-austenite esimweni senethiwekhi, okwenza amandla, ipulasitiki kanye nokuqina komthelela wensimbi kubaluleke kakhulu. nqaba.

(2) I-Isothermal Annealing. I-Isothermal annealing ibhekisela ekushiseni kwensimbi okuphonswayo ukuya ku-20 °C - 30 °C ngaphezu kwe-Ac3 (noma i-Ac1), ngemva kokubamba isikhathi esithile, ukupholisa ngokushesha izinga lokushisa eliphakeme lejika le-subcooled austenite isothermal transformation curve, bese ibamba isikhathi esithile. isikhathi (i-Pearlite transformation zone). Ngemuva kokuthi i-austenite iguqulwe ibe yi-pearlite, ipholisa kancane kancane.

(3) I-Spheroidizing Annealing. I-Spheroidizing annealing iwukushisa izinsimbi zensimbi zibe izinga lokushisa elingaphezudlwana kwe-Ac1, bese ngemva kwesikhathi eside sokugcina ukushisa, usimende wesibili ensimbi ushintsha ngokuzenzakalelayo ube usimende oyimbudumbudu (noma oyindilinga), bese ngesivinini esiphansi Ukwelashwa kokushisa. inqubo ukupholisa ekamelweni lokushisa.

Inhloso ye-spheroidizing annealing ihlanganisa: ukunciphisa ubulukhuni; ukwenza iyunifomu yesakhiwo se-metallographic; ukuthuthukisa ukusebenza kokusika nokulungiselela ukucisha.

I-Spheroidizing annealing isebenza kakhulu kuzinsimbi ze-eutectoid nezinsimbi ze-hypereutectoid (okuqukethwe kwekhabhoni okukhulu kuno-0.77%) njengensimbi yensimbi ye-carbon, i-alloy spring steel, i-rolling bearing kanye ne-alloy tool steel.

(4) Ukunciphisa ingcindezi nokufakwa kabusha kwekristalu. I-annealing yokunciphisa ingcindezi ibizwa nangokuthi i-anealing lokushisa eliphansi. Kuyinqubo lapho izinsimbi zensimbi zishiselwa khona zibe ngaphansi kwezinga lokushisa le-Ac1 (400 °C - 500 °C), bese ligcinwa isikhathi esithile, bese lipholiswa kancane kancane libe izinga lokushisa elilingana negumbi. Inhloso yokunciphisa ingcindezi ukuqeda ingcindezi yangaphakathi yokulingisa. Isakhiwo se-metallographic sensimbi ngeke sishintshe phakathi nenqubo yokunciphisa ukucindezeleka. I-recrystallization annealing isetshenziselwa ikakhulukazi ukuqeda ukwakheka okuhlanekezelwe okubangelwa ukucubungula okubandayo nokuqeda ukuqina komsebenzi. Izinga lokushisa lokushisisa le-recrystallization annealing liyi-150 °C - 250 °C ngaphezu kwezinga lokushisa lecrystallization. I-recrystallization annealing ingaphinda yakhe izinhlamvu zekristalu ezinde zibe amakristalu afanayo alinganayo ngemva kokuguqulwa okubandayo, ngaleyo ndlela kuqede umphumela wokuqina komsebenzi.

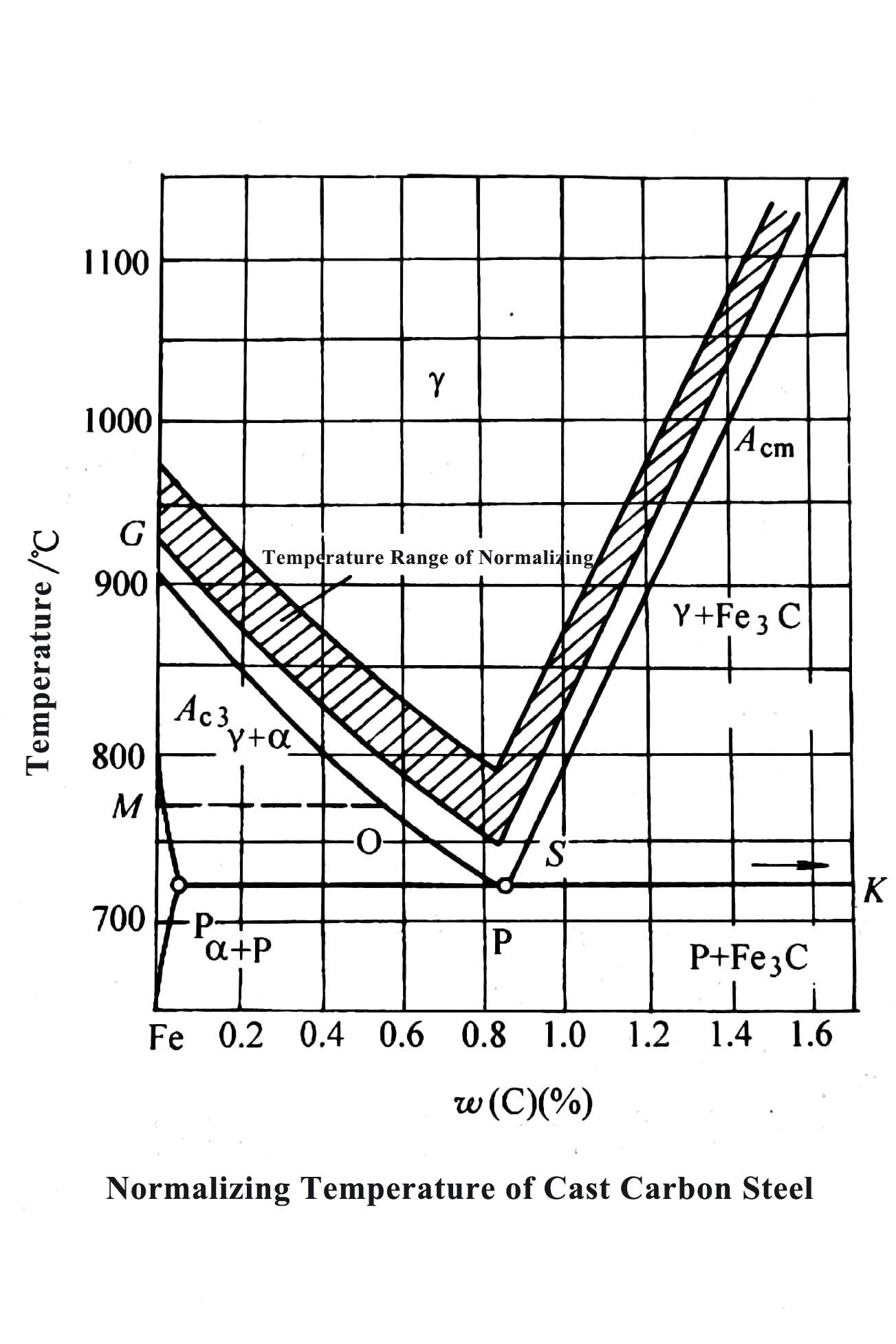

2) Ukwejwayelekile

I-normalizing yindlela yokwelapha ukushisa lapho insimbi ifudunyezwa ibe ngu-30 °C - 50 °C ngaphezu kwe-Ac3 (hypoeutectoid steel) kanye ne-Acm (hypereutectoid steel), futhi ngemva kwesikhathi sokulondoloza ukushisa, ipholiswa ezingeni lokushisa elilingana negumbi emoyeni noma ngaphakathi. umoya ophoqelelwe. indlela. Ukwenza okujwayelekile kunezinga lokupholisa elisheshayo kune-anneal, ngakho-ke ukwakheka okujwayelekile kucolekile kunesakhiwo esine-anneal, futhi amandla aso nobulukhuni nakho kuphakeme kunalokho kwesakhiwo esine-anneal. Ngenxa yomjikelezo omfushane wokukhiqiza kanye nokusetshenziswa okuphezulu kwemishini ye-normalization, i-normalization isetshenziswa kabanzi ekubunjweni kwensimbi okuhlukahlukene.

Inhloso ye-normalization ihlukaniswe ngezigaba ezintathu ezilandelayo:

(1) Ukujwayela njengokwelashwa kokushisa kokugcina

Ngokusakazwa kwensimbi okunezidingo zamandla aphansi, ukujwayela kungasetshenziswa njengokwelashwa kokushisa kokugcina. I-normalizing ingacwenga okusanhlamvu, i-homogenize isakhiwo, inciphise okuqukethwe kwe-ferrite ensimbi ye-hypoeutectoid, ikhulise futhi ihlanze okuqukethwe kwe-pearlite, ngaleyo ndlela ithuthukise amandla, ubulukhuni nokuqina kwensimbi.

(2) Ukujwayela njengokwelashwa kwangaphambi kokushisa

Ukuze uthole ukukhishwa kwensimbi enezingxenye ezinkulu, ukujwayelekile ngaphambi kokucisha noma ukucisha kanye nokushisa (ukucima nokushisa okuphezulu kokushisa) kungaqeda isakhiwo se-Widmanstatten kanye nesakhiwo esinamabhande, futhi sithole isakhiwo esihle nesifanayo. Ukuze usimende wenethiwekhi okhona kuma-carbon steels kanye nezinsimbi ze-alloy tool ezinokuqukethwe kwekhabhoni okukhulu kuno-0.77%, ukujwayelekile kunganciphisa okuqukethwe kwe-cementite yesibili futhi kuvimbele ukuthi kungabeki inethiwekhi eqhubekayo, ukulungiselela inhlangano i-spheroidizing annealing .

(3) Thuthukisa ukusika ukusebenza

Ukujwayela kungathuthukisa ukusebenza kokusika kwensimbi ephansi ye-carbon. Ukuqina kokusakazwa kwensimbi ye-carbon steel kuphansi kakhulu ngemva kokuhushulwa, futhi kulula ukunamathela kummese ngesikhathi sokusika, okuholela ekuqineni okukhulu kwendawo. Ngokusebenzisa ukwelashwa kokushisa okujwayelekile, ubulukhuni bensimbi ephansi ye-carbon castings bungakhuphuka bufinyelele ku-140 HBW - 190 HBW, obuseduze nobulukhuni bokusika obufanele, ngaleyo ndlela kuthuthukise ukusebenza kokusika.

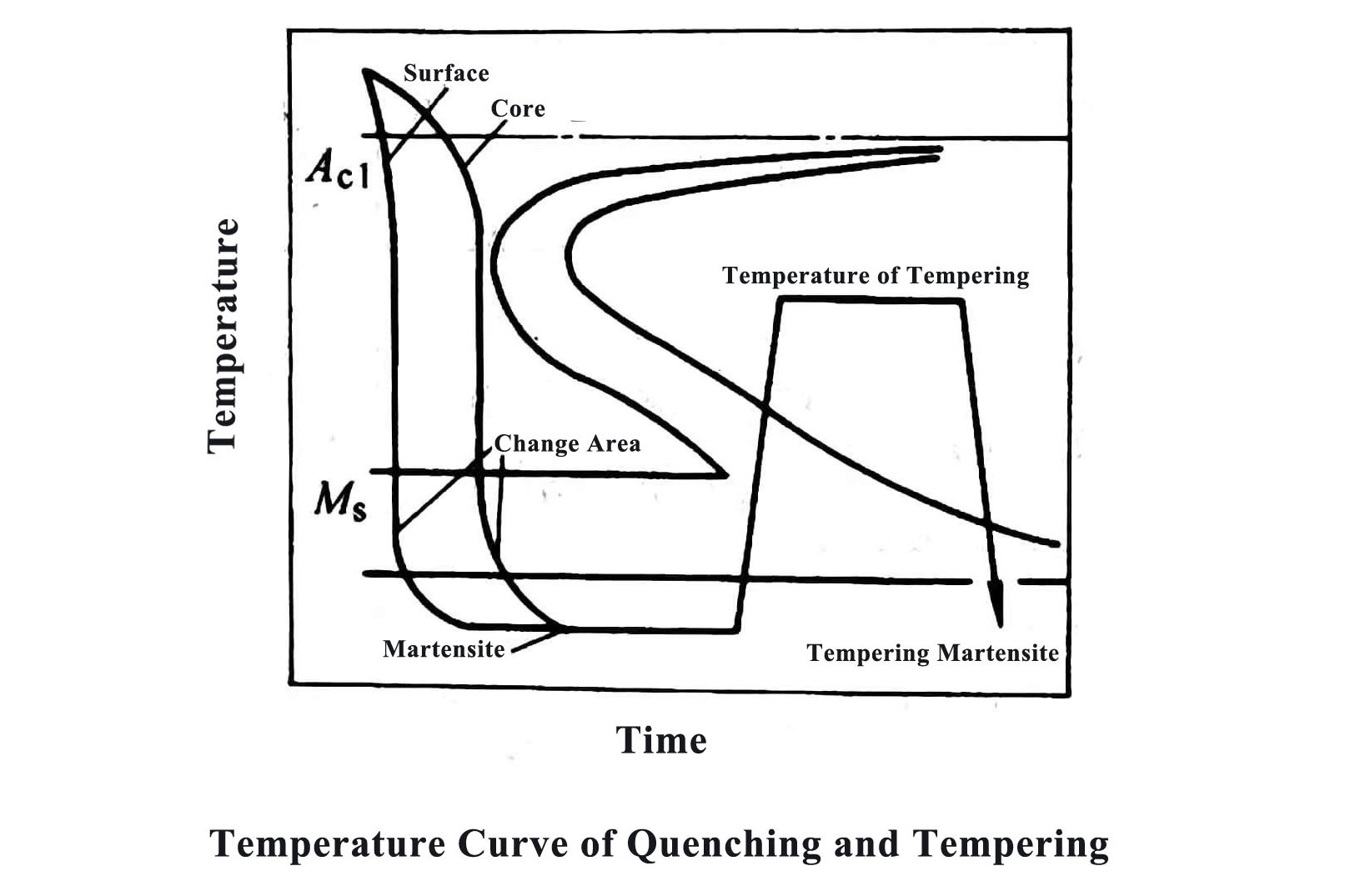

3) Ukushisa

Ukucisha inqubo yokwelapha ukushisa lapho izinsimbi zensimbi zishiselwa kuzinga lokushisa elingaphezulu kwe-Ac3 noma i-Ac1, bese lipholiswa ngokushesha ngemva kokubamba isikhathi esithile ukuze kutholwe isakhiwo se-martensitic esiphelele. Ama-castings ensimbi kufanele ancishiswe ngesikhathi ngemuva kokushisa kakhulu ukuze kuqedwe ingcindezi yokucisha futhi athole izakhiwo ezidingekayo ezibanzi zemishini.

(1) Ukucima izinga lokushisa

Izinga lokushisa elicishayo lensimbi ye-hypoeutectoid lingu-30℃-50℃ ngaphezu kwe-Ac3; izinga lokushisa elicishayo lokushisisa lensimbi ye-eutectoid nensimbi ye-hypereutectoid ingu-30℃-50℃ ngaphezu kwe-Ac1. I-Hypoeutectoid carbon steel iyashiswa ezingeni lokushisa elishiwo ngenhla ukuze kutholwe i-austenite enhle, futhi isakhiwo esihle se-martensite singatholakala ngemva kokucisha. Insimbi ye-eutectoid nensimbi ye-hypereutectoid yenziwe i-spheroidized futhi yafakwa ngaphambi kokucisha nokushisisa, ngakho-ke ngemva kokushisisa kufika ku-30℃-50℃ ngaphezulu kwe-Ac1 futhi yaqinisekiswa ngokungaphelele, isakhiwo siyi-austenite futhi singancibilikisiwe izinhlayiyana zomzimba we-Carbon ocwebile ongancibilikisiwe. Ngemva kokucisha, i-austenite iguqulwa ibe i-martensite, futhi izinhlayiya ze-cementite ezingancibilikisiwe zigcinwa. Ngenxa yokuqina okuphezulu kwe-cementite, akugcini nje ukunciphisa ubulukhuni bensimbi, kodwa futhi kuthuthukisa ukumelana kwayo kokugqoka. Isakhiwo esivamile esicishiwe sensimbi ye-hypereutectoid yi-martensite ecwebile, futhi usimende ocolile oyimbudumbudu kanye nenani elincane le-austenite egciniwe kusakazwa ngokulinganayo ku-matrix. Lesi sakhiwo sinamandla aphezulu nokumelana nokugqoka, kodwa futhi sinezinga elithile lokuqina.

(2) Indawo yokupholisa yokucisha inqubo yokwelapha ukushisa

Inhloso yokucisha ukuthola i-martensite ephelele. Ngakho-ke, izinga lokupholisa lensimbi yensimbi ngesikhathi sokucisha kufanele libe likhulu kunezinga lokupholisa elibalulekile lensimbi yensimbi, ngaphandle kwalokho isakhiwo se-martensite kanye nezakhiwo ezihambisanayo azikwazi ukutholwa. Kodwa-ke, izinga lokupholisa eliphezulu kakhulu lingaholela kalula ekushintshashintsheni noma ekuqhekekeni kokusakazwa. Ukuze kuhlangatshezwane nezidingo ezingenhla ngesikhathi esifanayo, indawo yokupholisa efanele kufanele ikhethwe ngokuya ngezinto zokulingisa, noma indlela yokupholisa ngesiteji kufanele yamukelwe. Ezingeni lokushisa elingu-650℃-400℃, izinga lokuguqulwa kwe-isothermal le-austenite yensimbi epholile likhulu kunawo wonke. Ngakho-ke, lapho ukulingisa kucinywa, ukupholisa ngokushesha kufanele kuqinisekiswe kuleli banga lokushisa. Ngaphansi kwephoyinti lika-Ms, izinga lokupholisa kufanele lihambe kancane ukuze kuvinjwe ukuwohloka noma ukuqhekeka. Indlela yokucisha ngokuvamile isebenzisa amanzi, isixazululo esinamanzi noma uwoyela. Esigabeni sokucisha noma ukuqinisa, imidiya evame ukusetshenziswa ihlanganisa amafutha ashisayo, insimbi encibilikisiwe, usawoti oncibilikisiwe noma i-alkali encibilikisiwe.

Umthamo wokupholisa wamanzi endaweni yokushisa ephezulu engu-650℃-550℃ unamandla, futhi umthamo wokupholisa wamanzi endaweni yokushisa ephansi engu-300℃-200℃ unamandla kakhulu. Amanzi afaneleka kakhulu ukucisha nokupholiswa kwe-carbon steel castings enomumo olula kanye nezingxenye ezinkulu eziphambanayo. Uma isetshenziselwa ukucisha nokupholisa, izinga lokushisa lamanzi ngokuvamile alikho ngaphezu kuka-30°C. Ngakho-ke, ngokuvamile kwamukelwa ukuqinisa ukujikeleza kwamanzi ukuze kugcinwe izinga lokushisa lamanzi ngaphakathi kwebanga elifanele. Ngaphezu kwalokho, ukushisa usawoti (NaCl) noma i-alkali (NaOH) emanzini kuzokwandisa kakhulu umthamo wokupholisa wesixazululo.

Inzuzo enkulu yamafutha njengendlela yokupholisa ukuthi izinga lokupholisa endaweni yokushisa ephansi ye-300 ℃-200 ℃ liphansi kakhulu kunalelo lamanzi, elinganciphisa kakhulu ukucindezeleka kwangaphakathi kwe-workpiece ecishiwe futhi kunciphise amathuba okuguqulwa. nokuqhekeka kokubunjwa. Ngaso leso sikhathi, amandla okupholisa kawoyela ebangeni lokushisa eliphakeme elingu-650℃-550℃ aphansi kakhulu, okuphinde kube yinkinga enkulu kawoyela njengendawo yokucisha. Izinga lokushisa likawoyela wokucisha ngokuvamile lilawulwa ku-60℃-80℃. Amafutha asetshenziswa kakhulu ekucimeni kokukhishwa kwensimbi ye-alloy enobumo obuyinkimbinkimbi kanye nokucisha ukukhishwa kwensimbi ye-carbon enezingxenye ezincane eziphambanayo kanye nokwakheka okuyinkimbinkimbi.

Ukwengeza, usawoti oncibilikisiwe ubuye usetshenziswe ngokujwayelekile njengendawo yokucisha, eba yindawo yokugeza usawoti ngalesi sikhathi. Ibhavu likasawoti libonakala ngephuzu eliphezulu lokubilisa futhi umthamo walo wokupholisa uphakathi kwamanzi namafutha. Ukugeza usawoti kuvame ukusetshenziselwa ukucindezela kanye nokucisha isiteji, kanye nokwelapha ama-castings anezimo eziyinkimbinkimbi, izilinganiso ezincane kanye nezidingo eziqinile zokuguqulwa.

4) Ukushisa

I-Tempering ibhekisela enkambisweni yokwelapha ukushisa lapho izinsimbi ezicishiwe noma ezijwayelekile zishiselwa ezingeni lokushisa elikhethiwe eliphansi kunephuzu elibalulekile le-Ac1, futhi ngemva kokubamba isikhathi esithile, zipholiswa ngezinga elifanele. Ukwelashwa kokushisa okushisa kungashintsha isakhiwo esingazinzile esitholakala ngemva kokucisha noma ukujwayelekile sibe isakhiwo esizinzile ukuze kuqedwe ukucindezeleka futhi kuthuthukise i-plasticity kanye nokuqina kokusakazwa kwensimbi. Ngokuvamile, inqubo yokwelapha ukushisa yokucisha kanye nokwelashwa kokushisa okuphezulu kubizwa ngokuthi ukucisha kanye nokwelashwa kokushisa. Ama-castings ensimbi acishiwe kufanele ancishiswe ngesikhathi, futhi ukukhishwa kwensimbi okujwayelekile kufanele kuncishiswe uma kunesidingo. Ukusebenza kwezinsimbi zensimbi ngemva kokushisa kuncike ekushiseni okushisayo, isikhathi kanye nenani lezikhathi. Ukwanda kwezinga lokushisa elishisayo kanye nokwandiswa kwesikhathi sokubamba nganoma isiphi isikhathi akukwazi nje ukukhulula ukucindezeleka okucishayo kokusakazwa kwensimbi, kodwa futhi kuguqule i-martensite ecishiwe engazinzile ibe yi-martensite epholile, i-troostite noma i-sorbite. Amandla nokuqina kokukhishwa kwensimbi kuyancishiswa, futhi ipulasitiki ithuthukiswa kakhulu. Kwezinye izinsimbi ze-alloy ezimaphakathi ezinezakhi ze-alloying ezakha ngokuqinile i-carbides (njenge-chromium, i-molybdenum, i-vanadium ne-tungsten, njll.), ubulukhuni buyanyuka futhi ukuqina kuyehla lapho ukushisa ku-400℃-500℃. Lesi simo sibizwa ngokuthi ukuqina kwesibili, okungukuthi, ukuqina kwensimbi ephonsiwe esimweni esishisayo kufinyelela phezulu. Ekukhiqizeni kwangempela, insimbi eyingxube yengxubevange ephakathi enezici zokuqina kwesibili idinga ukuthukutheliswa izikhathi eziningi.

(1) Ukushisa okuphansi kwezinga lokushisa

Izinga lokushisa eliphansi le-temperature tempering liyi-150℃-250℃. Ukushisa okuphansi kwezinga lokushisa kungathola isakhiwo se-martensite esishisayo, esisetshenziselwa ikakhulukazi ukucisha insimbi ephezulu ye-carbon kanye nokucisha insimbi ephezulu ye-alloy. I-tempered martensite ibhekisela esakhiweni se-cryptocrystalline martensite kanye nama-carbides amahle ayimbudumbudu. Isakhiwo sensimbi ye-hypoeutectoid ngemuva kokushisa okuphansi kwezinga lokushisa yi-martensite; ukwakheka kwensimbi ye-hypereutectoid ngemuva kokushisa okuphansi kwezinga lokushisa yi-martensite + carbides + egcinwe i-austenite. Inhloso yokushisa okuphansi kwezinga lokushisa ukuthuthukisa ngokufanelekile ukuqina kwensimbi ecishiwe kuyilapho kugcinwa ubulukhuni obuphezulu (58HRC-64HRC), amandla aphezulu nokumelana nokuguga, kuyilapho kunciphisa ngokuphawulekayo ukucindezelwa kokucisha kanye nokuqina kokusakazwa kwensimbi.

(2) Ukushisa okumaphakathi

Izinga lokushisa elipholile eliphakathi nendawo ngokuvamile liphakathi kuka-350℃-500℃. Isakhiwo ngemva kokushisa ekushiseni okuphakathi yinani elikhulu le-cementite elihlanjululwe kahle elihlakazekile futhi lisakazwa ku-matrix ye-ferrite, okungukuthi, isakhiwo se-troostite esithambile. I-ferrite esakhiweni se-troostite epholile isagcina isimo se-martensite. Ukucindezeleka kwangaphakathi kokusakazwa kwensimbi ngemva kokushisa kuyaqedwa, futhi banomkhawulo ophezulu wokunwebeka kanye nomkhawulo wesivuno, amandla aphakeme nobulukhuni, kanye nepulasitiki enhle nokuqina.

(3) Ukushisa okuphezulu

Izinga lokushisa eliphezulu lokwehlisa izinga lokushisa ngokuvamile liba ngu-500°C-650°C, futhi inqubo yokwelapha ukushisa ehlanganisa ukucisha kanye nezinga lokushisa eliphezulu okulandelayo ngokuvamile libizwa ngokuthi ukwelashwa kokucisha nokushisa. Isakhiwo ngemva kokushisa okuphezulu kokushisa yi-sorbite epholile, okungukuthi, i-cementite ehlanjululwe kahle kanye ne-ferrite. I-ferrite ku-sorbite eqinile i-polygonal ferrite edlula ukubunjwa kabusha. Ukukhishwa kwensimbi ngemva kokushisa okuphezulu kwe-temperature kunezakhiwo ezinhle eziphelele zemishini ngokwamandla, ipulasitiki kanye nokuqina. Ukushisa okuphezulu kokushisa kusetshenziswa kakhulu ku-medium carbon steel, insimbi ephansi ye-alloy, nezingxenye ezihlukahlukene ezibalulekile zesakhiwo ezinamandla ayinkimbinkimbi.

5) Solid SolutionUkwelashwa

Inhloso eyinhloko yokwelashwa kwesixazululo ukuncibilikisa ama-carbides noma ezinye izigaba ezincishisiwe kwisisombululo esiqinile ukuze kutholwe isakhiwo sesigaba esisodwa esine-supersaturated. Ukufakwa kwensimbi engagqwali ye-austenitic, insimbi ye-austenitic manganese kanye nemvula eqinisa insimbi engagqwali ngokuvamile kufanele kube isixazululo esiqinile. Ukukhethwa kokushisa kwesisombululo kuncike ekubunjweni kwamakhemikhali kanye nomdwebo wesigaba sensimbi ekhonjiwe. Izinga lokushisa le-austenitic manganese steel castings ngokuvamile liyi-1000 ℃ - 1100 ℃; izinga lokushisa le-austenitic chromium-nickel castings steel stainless steel ngokuvamile lingu-1000℃-1250℃.

Uma kuphezulu okuqukethwe kwekhabhoni kunsimbi ekhonjiwe kanye nezinto ezingancibiliki kakhulu, izinga lokushisa layo lesixazululo esiqinile kufanele libe phezulu. Ukuze uthole imvula eqinisa insimbi equkethe ithusi, ubulukhuni bokubunjwa kwensimbi buyanda ngenxa yemvula yezigaba ezicebile zethusi eliqinile esimweni sokusakazwa ngesikhathi sokupholisa. Ukuze kuthambise isakhiwo futhi kuthuthukiswe ukusebenza kokucubungula, izinsimbi zensimbi zidinga ukuphathwa ngesisombululo esiqinile. Izinga lokushisa layo eliqinile lesisombululo ngu-900℃-950℃.

6) Ukwelashwa Kwemvula Kokuqina

Ukwelashwa kokuqina kwemvula kuwukwelapha okuqinisa ukuhlakazwa okwenziwa phakathi kwezinga lokushisa elishisayo, okwaziwa nangokuthi ukuguga kokwenziwa. Ingqikithi yokwelashwa kokuqina kwemvula iwukuthi emazingeni okushisa aphezulu, ama-carbides, ama-nitrides, ama-intermetallic compounds nezinye izigaba ezimaphakathi ezingaqinile ziyawa zisuka kusixazululo esiqinile esine-supersaturated bese zihlakazeka ku-matrix, ngaleyo ndlela kwenze insimbi ekhonjiwe iphelele.

Ukushisa kokwelashwa kokuguga kuthinta ngokuqondile ukusebenza kokugcina kwensimbi yensimbi. Uma izinga lokushisa lokuguga liphansi kakhulu, isigaba sokuqina kwemvula sizokwehla kancane; uma izinga lokushisa lokuguga liphezulu kakhulu, ukuqoqwa kwesigaba esinciphile kuzodala ukuguga, futhi ukusebenza okuhle kakhulu ngeke kutholakale. Ngakho-ke, i-foundry kufanele ikhethe izinga lokushisa elifanele lokuguga ngokusho kwebanga lensimbi yensimbi kanye nokusebenza okucacisiwe kwensimbi yensimbi. Izinga lokushisa lokuguga lensimbi evikela ukushisa ye-austenitic ngokuvamile liyi-550 ℃-850 ℃; izinga lokushisa eligugayo lensimbi enamandla kakhulu yezulu eliqinisa insimbi ngokuvamile lingama-500 ℃.

I-7) Ukwelashwa Kwe-Stress Relief

Inhloso yokwelashwa kokushisa kokunciphisa ingcindezi iwukuqeda ingcindezi yokuphonsa, ukucisha ingcindezi nokucindezeleka okwenziwe ngomshini, ukuze kuzinziswe usayizi wokusakaza. Ukwelashwa kokushisa okudambisa ingcindezi kuvame ukushisisa ku-100°C-200°C ngaphansi kwe-Ac1, bese kugcinwa isikhathi esithile, bese kupholiswa ngesithando somlilo. Isakhiwo sensimbi yensimbi asizange sishintshe phakathi nenqubo yokunciphisa ukucindezeleka. Ukulingwa kwensimbi ye-Carbon, ukulingwa kwensimbi ye-alloy ephansi kanye nokulingwa kwensimbi enengxubevange ephezulu konke kungabhekana nokwelashwa kokukhululeka kwengcindezi.

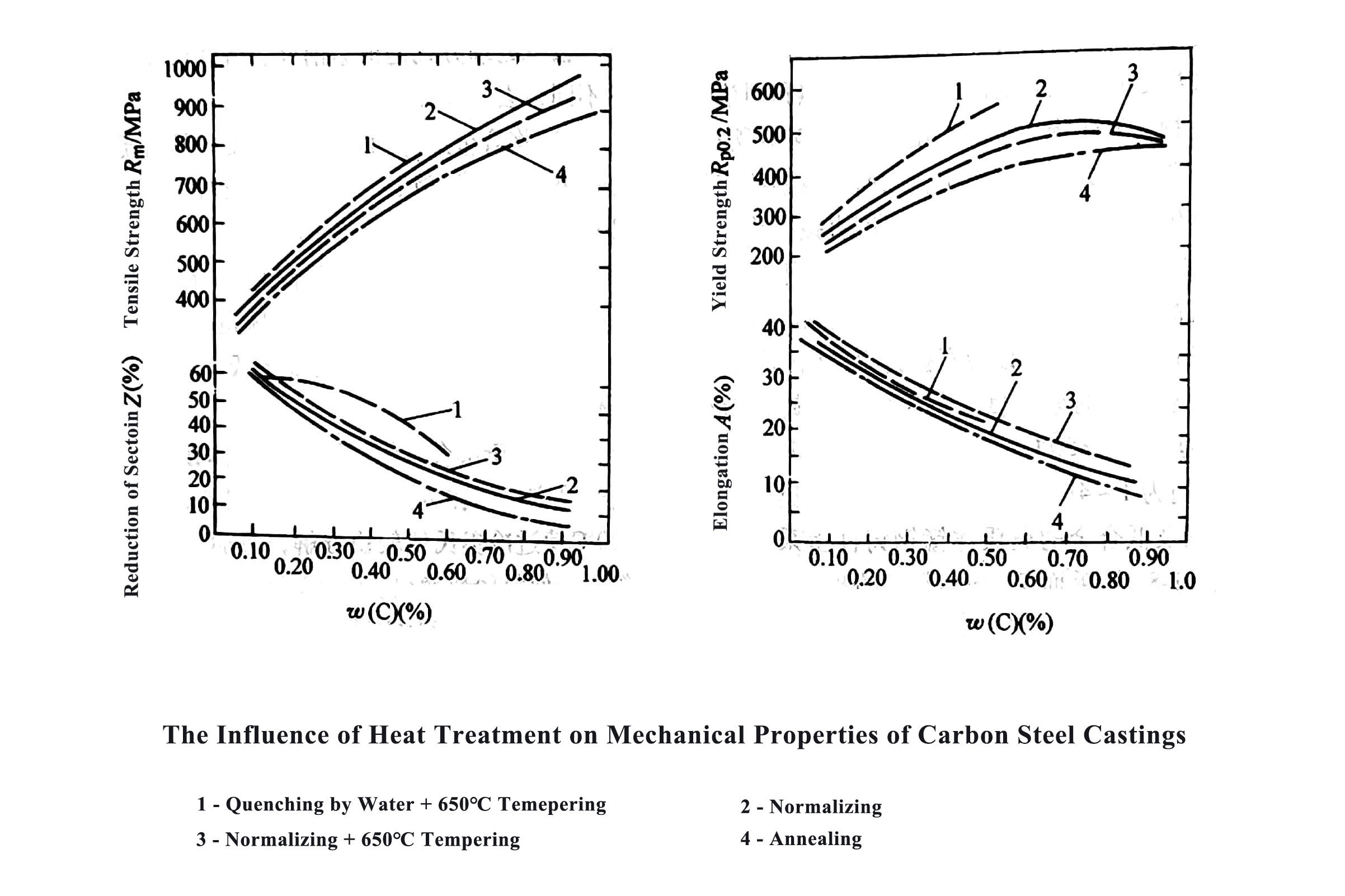

4. Umthelela Wokwelashwa Kokushisa Ezimpahleni Zokusakaza Kwensimbi

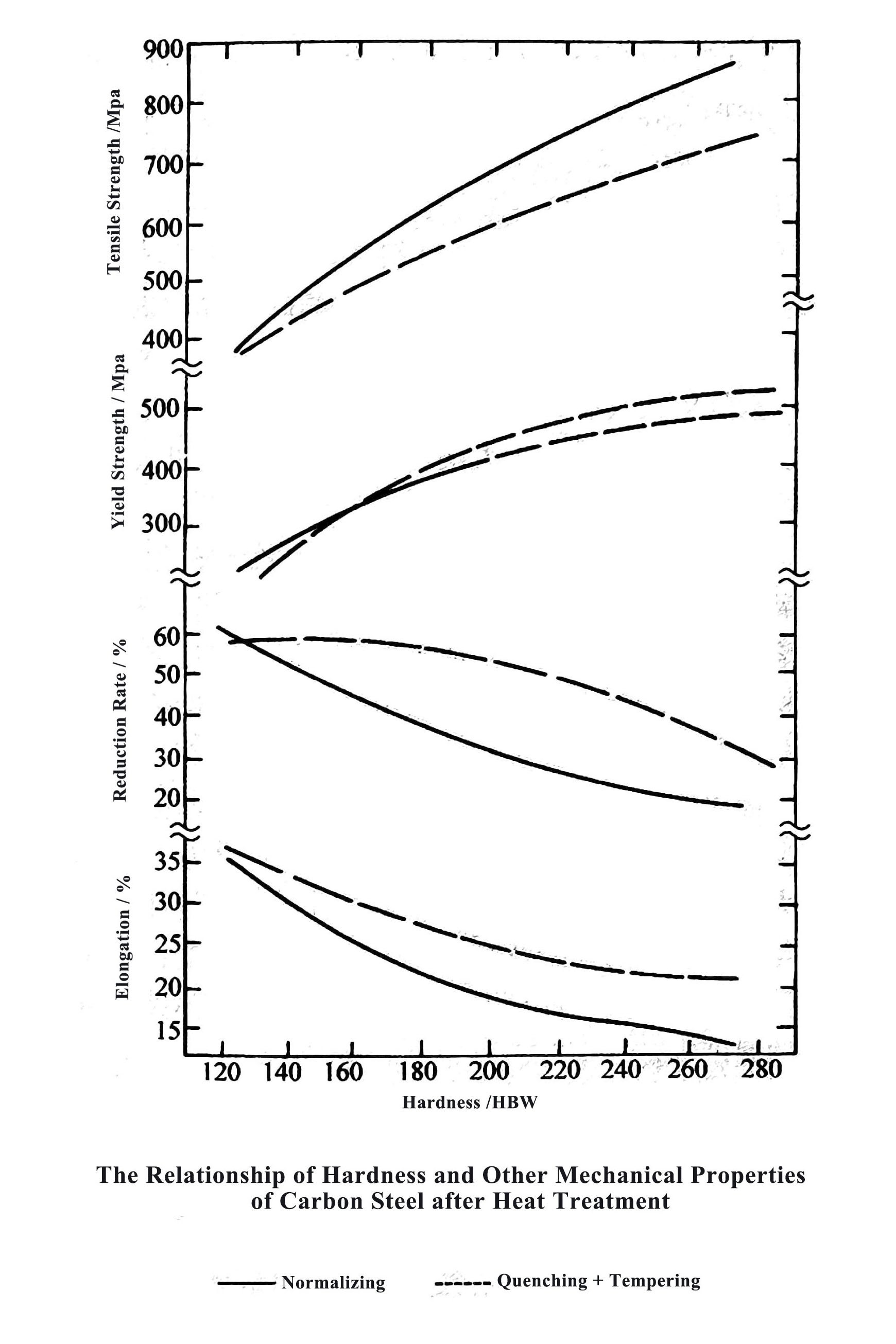

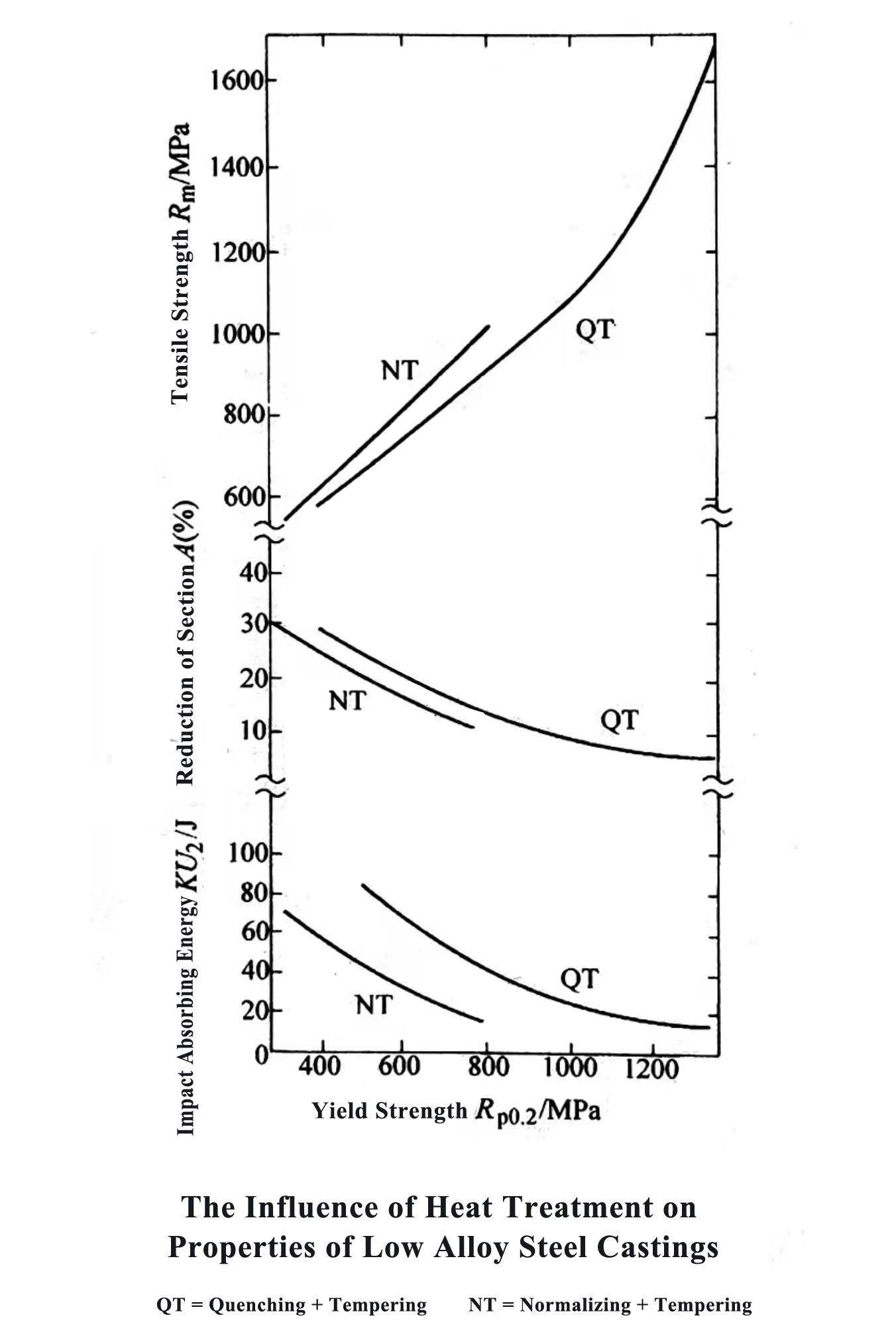

Ngaphezu kokusebenza kokusakazwa kwensimbi kuye ngokwakheka kwamakhemikhali kanye nenqubo yokuphonsa, izindlela ezihlukene zokwelapha ukushisa nazo zingasetshenziswa ukuze kube nezakhiwo ezinhle kakhulu eziphelele zemishini. Inhloso evamile yenqubo yokwelapha ukushisa ukuthuthukisa ikhwalithi yokulingisa, ukunciphisa isisindo sokulingisa, ukunweba impilo yesevisi nokunciphisa izindleko. Ukwelashwa kokushisa kuyindlela ebalulekile yokuthuthukisa izakhiwo zemishini ye-castings; izakhiwo zemishini ye-castings ziyinkomba ebalulekile yokwahlulela umphumela wokwelapha ukushisa. Ngaphezu kwalezi zakhiwo ezilandelayo, i-foundry kumele futhi icabangele izici ezifana nezinqubo zokucubungula, ukusika ukusebenza kanye nezidingo zokusetshenziswa kwe-castings lapho ukushisa kwensimbi yokushisa.

1) Umthelela Wokwelashwa Kokushisa Emandleni Okusakazwa

Ngaphansi kwesimo sokubunjwa kwensimbi efanayo, amandla okukhishwa kwensimbi ngemva kwezinqubo ezahlukene zokwelashwa kokushisa anomkhuba wokwanda. Ngokuvamile, amandla aqinile we-carbon steel castings kanye ne-low alloy steel castings angafinyelela ku-414 Mpa-1724 MPa ngemva kokwelashwa kokushisa.

2) Umthelela Wokwelashwa Kokushisa ku-Plasticity ye-Steel Castings

Isakhiwo se-as-cast se-castings yensimbi simahhadla futhi ipulasitiki iphansi. Ngemuva kokwelashwa okushisa, i-microstructure yayo kanye ne-plasticity izothuthukiswa ngokufanele. Ikakhulukazi i-plasticity ye-castings yensimbi ngemva kokucisha kanye nokwelashwa kokushisa (ukucima + ukushisa okuphezulu kokushisa) kuzothuthukiswa kakhulu.

3) Ukuqina kwe-Steel Castings

Inkomba yokuqina kokusakazwa kwensimbi ivamise ukuhlolwa ngokuhlolwa komthelela. Njengoba amandla nokuqina kokukhishwa kwensimbi kuyizinkomba ezimbili eziphikisanayo, i-Foundry kumele icabangele kabanzi ukuze ikhethe inqubo yokwelashwa kokushisa efanelekile ukuze kuzuzwe izakhiwo ezibanzi zemishini ezidingwa amakhasimende.

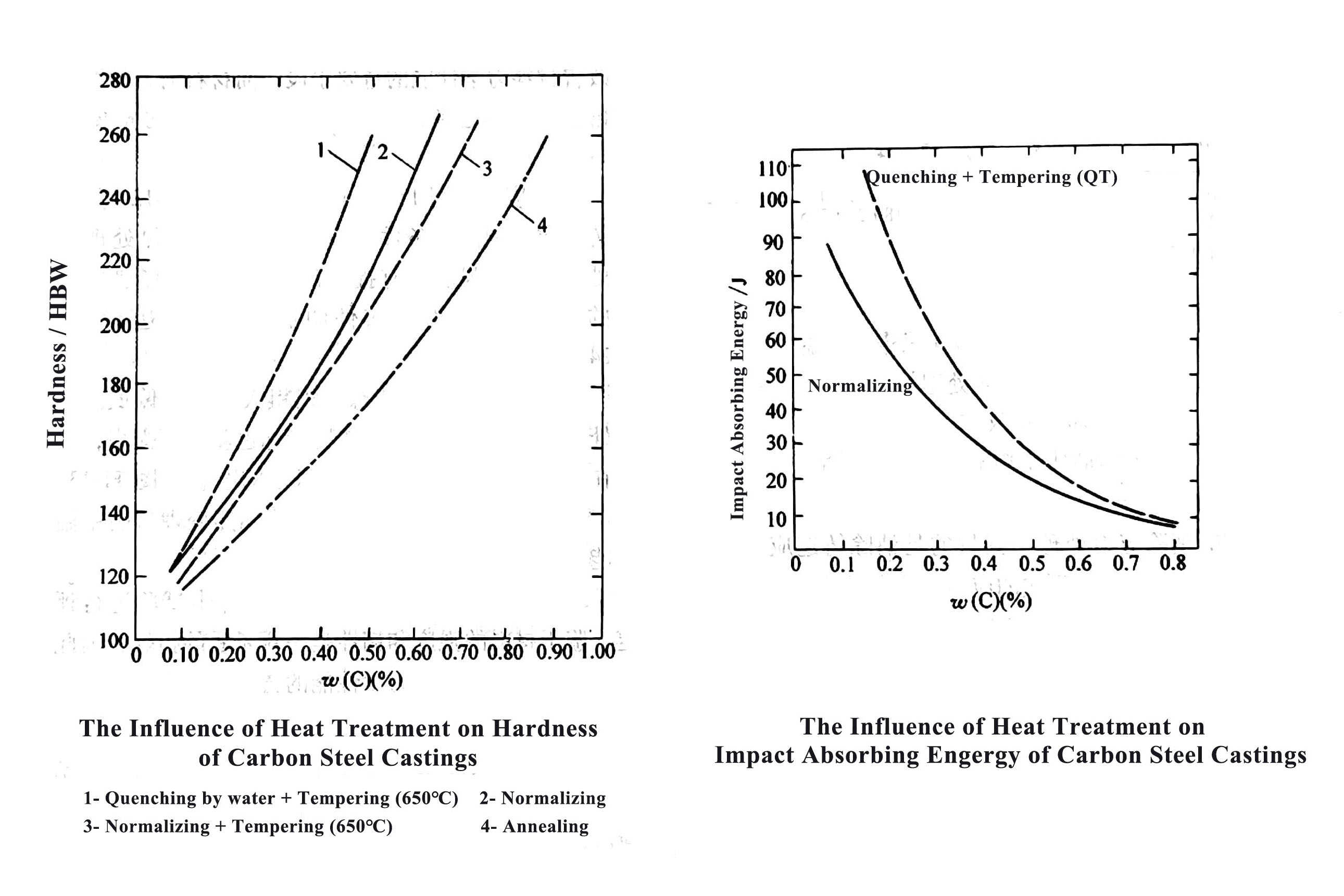

4) Umthelela Wokwelashwa Kokushisa Ebunzimeni Be-Casting

Lapho ukuqina kwensimbi ekhonjiwe kufana, ukuqina kwensimbi ekhonjiwe ngemva kokwelashwa kokushisa kungabonisa cishe amandla ensimbi ekhonjiwe. Ngakho-ke, ubulukhuni bungasetshenziswa njengenkomba enembile ukulinganisa ukusebenza kwensimbi ekhonjiwe ngemva kokwelashwa kokushisa. Ngokuvamile, ubulukhuni be-carbon steel castings bungafinyelela ku-120 HBW - 280 HBW ngemva kokwelashwa kokushisa.

Isikhathi sokuthumela: Jul-12-2021