Investment Casting Foundry

Ukufakwa kwe-investimenti, okubuye kwaziwe njengokuphonsa kwe-wax elahlekile noma ukuphonsa ngokunemba, kuyinqubo eseyenziwe izinkulungwane zeminyaka, inqubo elahlekile ye-wax ingenye yezindlela zakudala ezaziwayo zokwakha insimbi.

Ngenxa yesakhiwo esiyinkimbinkimbi ku-dimension kanye ne-geometric, ukulingwa kwe-investimenti kukhiqizwa ukuze kufinyelele umumo wenetha noma eduze kwesimo senetha, kuncishiswe isidingo sezinqubo zesibili ezifana ne-lathing, ukujika noma okunye.CNC imishiniinqubo.

Ukutshala izimali kuyinqubo yokukhiqiza engalandelelwa emuva eminyakeni engu-5,000 edlule. Kusukela ngaleso sikhathi, lapho ingcina yezinyosi yenza iphethini, kuze kufike kubuchwepheshe obuphezulu banamuhla, izinto eziphikisayo kanye nama-alloys akhethekile, ukukhishwa kwe-wax elahlekile kuqinisekisa ukuthi izingxenye zekhwalithi ephezulu zikhiqizwa ngezinzuzo zokunemba, ukuphindaphinda, nobuqotho.

Ukutshala imali kususelwa eqinisweni lokuthi iphethini itshaliwe, noma izungezwe, ngento ephikisayo. Amaphethini we-wax adinga ukunakekelwa okwedlulele ngoba awanamandla ngokwanele ukumelana namandla okuhlangana nawo ngesikhathi sokwenza isikhunta.

Investment Casting Foundry

Esingakuzuzisa Ngokulahleka Kwe-Wax Investment Casting

Ukufakwa kokutshala kwe-wax okulahlekile okune-silica sol njengezinto ezihlanganisayo kungafinyelela ebangeni lokubekezelela i-dimensional CT4 ~ CT7 ngokuya nge-ISO 8062. Amathuluzi ethu ahlelwe ngokugcwele nezilawuli zenqubo yokuzenzakalela zivumela ukubekezelelana okungaguquguquki nokuphindaphindayo eduze kuka-± 0.1 mm. Iizingxenye zokuphonsa i-wax ezilahlekilezingaphinda zikhiqizwe ngosayizi obanzi, zingaba zincane zibe ngu-10 mm ubude x 10 mm ububanzi x 10 mm ukuphakama futhi zibe nesisindo esingango-0.01 kg, noma zibe nkulu njengo-1000 mm ubude futhi zibe nesisindo esingama-200 kg. .

I-RMC ingumkhiqizi ohamba phambili embonini wokusakazwa kokutshalwa kwezimali kwekhwalithi ephezulu ezinikele ekuletheni ikhwalithi enhle kakhulu, inani eliphakeme kanye nolwazi olukhethekile lwamakhasimende. I-RMC inolwazi, ubuchwepheshe kanye nezinqubo zokuqinisekisa ikhwalithi ukuze ilethe ngokungaguquki nangokuthembekile uhla olubanzi lokulingisa ngokucubungula okwengeziwe.

- • Ubukhulu Usayizi Wokusakaza: 1,000 mm × 800 mm × 800 mm

- • I-Cast Weight Range0.5 kg - 200 kg

- • Amandla onyaka:amathani ayi-3,000

- • Impahla Yebhondi Yokwakha I-Shell:I-Silica Sol, Ingilazi Yamanzi noma izingxube zayo.

- • Ukubekezelela Ukusakaza:CT4 ~ CT7 ngokwe-ISO 8062 noma ngesicelo.

Ukwenza Igobolondo Ngesikhathi Sokutshala Imali

Yiziphi Izinsimbi kanye nama-alloys esingawathululela ngokufaka utshalomali

Iisisekelo sokutshala imalikwa-RMC iyakwazi ukuhlangabezana nenhlobonhlobo yezinhlobonhlobo zezinto ezisetshenziswayo kanye nokucaciswa kwazo ngokuya ngamazinga we-ASTM, SAE, AISI, ACI, DIN, GOST, EN, ISO, kanye ne-GB. Sinama-alloys angaphezu kwe-100 ahlukene ayinsimbi futhi angeyona ayoni esiphonsa ngawo izingxenye sisebenzisa isakhiwo esiyinkimbinkimbi.

- • I-Grey Cast Iron:HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30, GG40; I-ASTM A48 I-Grey Iron Amabanga Ikilasi 20, Ikilasi 25, Ikilasi 30, Ikilasi 35, Ikilasi 40, Ikilasi 45, Ikilasi 50, Ikilasi 55, Ikilasi lama-60.

- • I-Ductile Cast Iron (I-Nodular Iron):I-China GB QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2; I-GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-400-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN- I-GJS-800-2; ASTM A536 Ductile Iron Amabanga 60-40-18, 65-45-12, 70-50-05, 80-60-03, 100-70-03, 120-90-02.

- •Insimbi Yekhabhoni:AISI 1020 ~ AISI 1060, C30, C40, C45.

- •I-alloy Steel:ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo, njll.

- •Insimbi engagqwali:AISI 304, AISI 304L, AISI 316, AISI 316L,I-AISI 347, AISI 430, 1.4401, 1.4404, 1.4408, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571, CF3, CF3M, CF8, CF8M... njll.

- •I-Duplex Stainless Steel (DSS)futhiI-Precipitation Hardening (PH) Insimbi Engagqwali

- • I-Brass, Bronze kanye namanye ama-Alloys asekelwe eCopper

- •I-Nickel Based Alloy (Inconel 625, Inconel 713, Inconel 718 njll), Ama-Cobalt Asekelwe Alloys

- • Insimbi engagqwali, insimbi engangeni emanzini olwandle, insimbi eshisa kakhulu, i-High-tensile Steel, i-Duplex Stainless Steel.

- • I-Aluminium Alloy A356, A360

- • Amanye Ama-alloys njengesicelo noma ngokusho kwe-ASTM, SAE, AISI, GOST, DIN, EN, ISO, kanye ne-GB.

I-Stainless Steel Investment Casting

Investment Casting Mold

I-Al Mold yokusakazwa kwe-wax elahlekile

Metal Mold for Investment Casting

Isikhunta se-Aluminium Alloy Esenziwe Ngokugcwele Sokusakaza Okunembile

Izinyathelo Zokutshala Kwemali Elahlekile

Ukusakazwa kwezimali kuyinqubo enezinyathelo eziningi ekhiqiza umumo oseduze nenethaukunemba ekubunjweni izingxenye. Inqubo iqala ngokuthi i-wax ijovwe edayini ukuze kwakhiwe iphethini yomkhiqizo oqediwe. Amaphethini abe esenamathiselwa emigoqweni ye-wax yokugijima ukuze akhe iqoqo.

Phakathi nenqubo yokutshala izimali, umshini okhethekile ucwilisa iqoqo ngokuphindaphindiwe ku-slurry ukuze uthuthukise igobolondo le-ceramic, bese i-wax ikhishwa ku-autoclave ye-steam. Uma i-wax isusiwe, igobolondo le-ceramic liyaxoshwa bese ligcwaliswa ngensimbi encibilikisiwe ukuze kwakhiwe ingxenye. Enye inzuzo yokutshala imali ukuthi i-wax ingasetshenziswa kabusha.

Ukufakwa kwe-investimenti (Inqubo yokuphonsa ingcina elahlekile) kudinga insimbi (imvamisa eyi-aluminium), i-wax, i-ceramic slurry, isithando somlilo, insimbi encibilikisiwe, neminye imishini edingekayo yokujova i-wax, ukuqhunyiswa kwesihlabathi, ukuwa okudlidlizayo, ukusika, nokugaya. Inqubo yokukhipha imali ngokuyinhloko ihilela lezi zinyathelo ezilandelayo:

1- Ukwenza i-Metal Die

Ngokusekelwe emidwebeni kanye nezidingo zengxenye efunwayo, insimbi iyafa noma isikhunta, ngokuvamile esiyi-aluminium, izoklanywa futhi ikhiqizwe. Umgodi uzokwakha usayizi ofanayo kanye nesakhiwo sengxenye efunwayo.

2- Umjovo we-wax

Futhi njengoba kwaziwa njengokwakheka kwephethini, Amaphethini okuphonsa we-wax alahlekile adalwa ngokujova ingcina encibilikisiwe ensimbini efa ngaphezulu.

3- I-Slurry Assembly

Amaphethini we-wax abe esenamathiselwa ohlelweni lokungena, okuvame ukuba yisethi yamashaneli lapho insimbi encibilikisiwe igelezela emgodini wokukhunta. Ngemva kwalokho, kwakhiwa isakhiwo esifana nesihlahla, esifanele ukukhiqizwa ngobuningi.

4- Shell Building

I-investimenti ye-investimenti yegobolondo yegobolondo yangaphandle yakhiwe ngokucwiliswa kubhavu we-ceramic bese imbozwa ngokushesha ngesihlabathi izikhathi ezimbalwa.

5- I-De-waxing

Ingaphakathi le-investment casting elinembile libe selikhishwa ngewax, elishiya ungqimba lwegobolondo le-ceramic langaphandle elingenalutho. Izimbobo ziyindawo efanayo nje yokulingisa oyifunayo.

6-Ukuhlaziywa Kwangaphambi Kokuthela

Ukuhlaziywa kwangaphambi kokuthelwa kusho ukuthi isizinda sidinga ukuhlola nokuhlaziya ukwakheka kwamakhemikhali ensimbi encibilikisiwe ukuze kubonakale ukuthi ayahlangabezana yini nezinombolo ezidingekayo noma inkanyezi. Ngezinye izikhathi, lokhu kuhlaziywa kwakungenziwa izikhathi eziningana.

7- Ukuthulula & Ukuqinisa

Igobolondo le-ceramic eline-cavity kufanele lishiswe ngaphambili ngaphambi kokuthulula. Lokhu kuvimbela ukushaqeka kanye negobolondo le-ceramic ekuqhekekeni lapho insimbi ewuketshezi ekushiseni okuphezulu ithululelwa emgodini.

8- Ukusaha noma Ukusika

Uma insimbi isipholile futhi yaqina, ingxenye/izingxenye ezibunjiwe zibe sezikhishwa eqoqweni lesihlahla sesistimu yokugenca ngokuzamazama, ukusika noma ukushwibilika kwengxenye ngayinye yabalingisi.

9- I-Shot Blasting kanye nokucutshungulwa kwesibili

Ingxenye yokuphonsa ibe seyenziwe ngendlela oyifisayo ngokugcwele ngokugaya noma ukwelashwa okungeziwe kokushisa. Ukucutshungulwa kwesibili noma ukwelashwa kwendawo nakho kungase kudingeke kuye ngezidingo zengxenye.

10-Ukupakisha Nokulethwa

Khona-ke izingxenye ezilahlekile zokuphonsa i-wax zizohlolwa ngokugcwele ubukhulu, indawo engaphezulu, izakhiwo zemishini nezinye izivivinyo ezidingekayo ngaphambi kokupakisha nokulethwa.

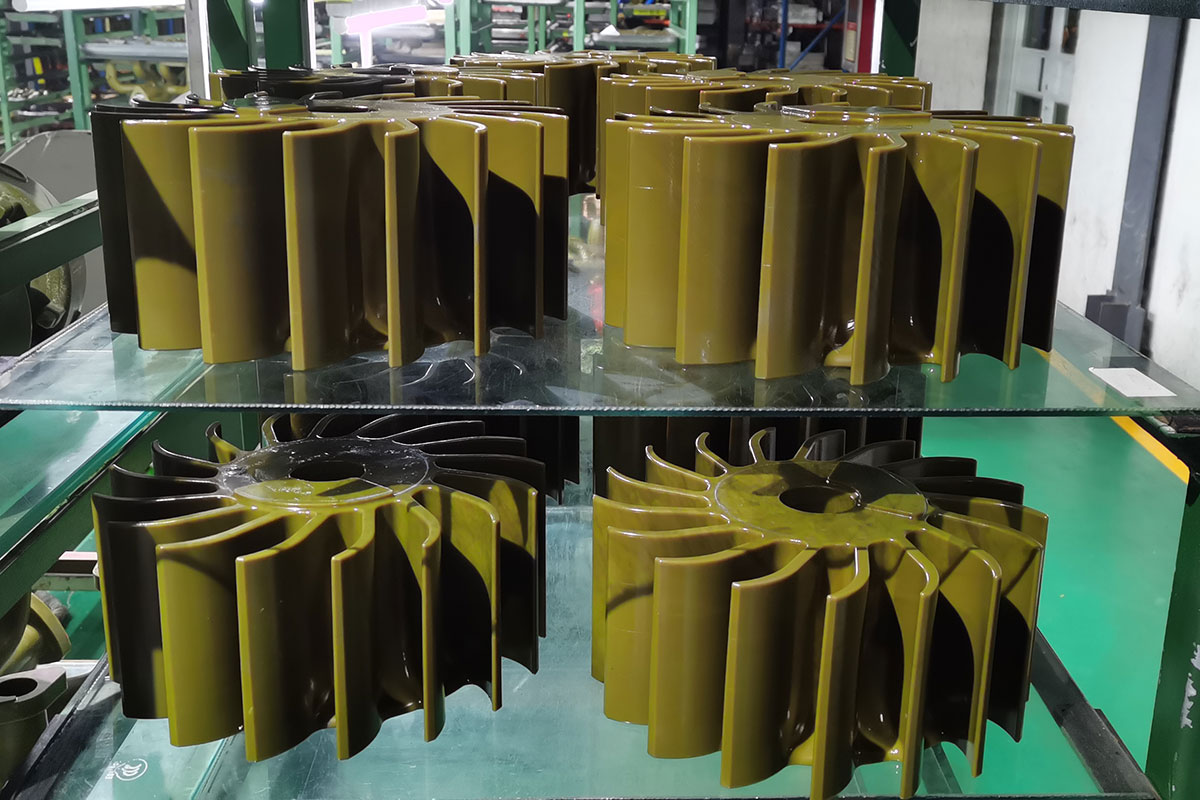

Amaphethini we-wax

Ukomisa Igobolondo

Ukupholisa kanye Nokuqinisa

Ukugaya Nokuhlanza

Sikuhlola Kanjani Ukutshala Kwezimali

- • Ukuhlaziywa kobuningi be-Spectrographic kanye nemanuwali

- • Ukuhlaziywa kwe-Metallographic

- • Ukuhlolwa kwe-Dimensional

- • CMM

- • Ukuhlolwa kokuqina kukaBrinell, Rockwell kanye noVickers

- • Ukuhlaziywa kwempahla yemishini

- • Ukuhlolwa komthelela wezinga lokushisa eliphansi nelivamile

- • Ukuhlolwa kwenhlanzeko

- • Ukuhlolwa kwe-UT, MT kanye ne-RT

- • Ibhalansi eqinile neDynamic

- • Ukuhlola Ukuvala Nokucindezela

I-Wax Replicas

Yiziphi Izinsiza Esithembele Kuzo Zokutshala Imali

I-Toolings Warehouse

Umjovo Wamaphethini Wengcina

Umjovo Wamaphethini Wengcina

Umshini Wokujova Ngewax

Ukwenza Igobolondo

Ukwenza Igobolondo

I-Shell Drying Workshop

Shell for Investment Casting

Ukomisa Igobolondo

Igobolondo Lilungele Ukusakaza

Ukupholisa kanye Nokuqinisa

Inqubo Yokutshala Imali

Iziphi Izimboni Ukutshalwa Kwethu Kwezimali Kwethu Ezisebenzayo

Izingxenye ezenziwe ngokufaka utshalomalizisetshenziselwa ukusakaza izinto ezihlukahlukene, okuhlanganisa izinga eliphezulu, izingxenye zezimboni ezisebenza kahle zezakhiwo eziyinkimbinkimbi.Ukusetshenziswa kwezingxenye zokutshala imali kuhlanganisa izinhlobonhlobo zezimboni, enkampanini yethu zivame ukusetshenziswa kulezi zindawo ezilandelayo:

| •Izingxenye ze-Valve kanye ne-Pump | • Izinto zokusebenza |

| • Amaloli Emisebenzi Enzima | • Izinsiza Zokulima |

| • Ezezimoto | •Ama-hydraulics |

| • Izinto zokwakha | • Izitimela Zesitimela |

Izicelo of Investment Castings

OkujwayelekileInvestment CastingsSiyakhiqiza

Singenza Okuningi ngokunikela nge-Investment Casting nezinye izinkonzo:

Kwa-RMC, siyaziqhenya ngokunikeza amakhasimende ethu isevisi kusukela ku-patter design kuyekuqedwe ukulingisakanye nezinqubo zesibili. Izinkonzo zethu zihlanganisa:

- - Idizayini Yephethini kanye Nezincomo Zezindleko Eziphansi.

- - Ukuthuthukiswa kwe-Prototype.

- - Ucwaningo Lokukhiqiza Nentuthuko.

- - Ukukhiqiza Ukuvumelana nezimo.

- - Iziqu kanye nokuhlolwa.

- - Ukwelashwa Kokushisa kanye Nokwelashwa Kwangaphandle kuyatholakala.

- - Outsourcing Manufacturing Amakhono

I-Stainless Steel Investment Castings

Kungani Ukhetha i-RMC Yokukhiqiza I-Investments Castings

Kunezizathu ezimbalwa zokukhetha i-RMC njengomthombo wakho wokusakazwa kokutshalwa kwezimali. Lapho uthatha isinqumo, ungase ukhathalele amaphuzu alandelayo esikwazi ukuwasebenzisa kahle:

- - Ithimba lobunjiniyela amalungu alo agxile emkhakheni wokulingisa insimbi.

- - Isipiliyoni esibanzi esinezingxenye zejometri eziyinkimbinkimbi

- - Uhlu olubanzi lwezinto zokwakha, kufaka phakathi ama-alloys ayoni kanye nama-non-ayoni

- - EndliniCNC imishiniamakhono

- - One-stop izixazululo for castings utshalomali kanye nenqubo yesibili

- - Ikhwalithi engaguquki iqinisekisiwe futhi ithuthuka njalo.

- - Ukusebenzisana okubandakanya abenzi bamathuluzi, onjiniyela, umsunguli, ochwepheshe bemishini kanye nochwepheshe bokukhiqiza.