Kwa-RMC Foundry, sisebenzisa ezinye izinqubo zokulingisa ukuze kusakazwe izinsimbi nama-alloys ngokwezidingo zekhasimende noma ngokusekelwe ekuthuthukisweni kwethu. Insimbi eyahlukene kanye nengxubevange ifaneleka enqubweni yayo yokulingisa ehamba phambili ngokucabangela izidingo zomsebenzisi wokugcina kanye nezindleko eziphumelelayo. Ngokwesibonelo, iinsimbi empungangokuvamile ilungele ukuphonswainqubo yokuphonsa isihlabathi, ngenkathi iinsimbi engagqwalikuvame ukuphonswa ukukhishwa kwe-investment wax elahlekile.

Kunezici eziningi okufanele sizicabangele lapho sikhetha izindlela zokuphonsa ezifanele, njengokusatshalaliswa kwezinto, isidingo sesisindo (ama-alloys e-Aluminium ne-Zinc alula kakhulu kunamanye ama-alloys), izakhiwo zemishini futhi uma kukhona ukusebenza okukhethekile okudingekayo ukumelana nokugqoka, ukumelana nokugqwala, ukumanzisa... njll. Uma sikhetha iukunemba kokulingisa(ngokuvamile ibhekisela ekufakweni kwe-investimenti), sizoba nesidingo esincane noma singekhoimishini, okungasindisa zonke izindleko zokukhiqiza kakhulu.

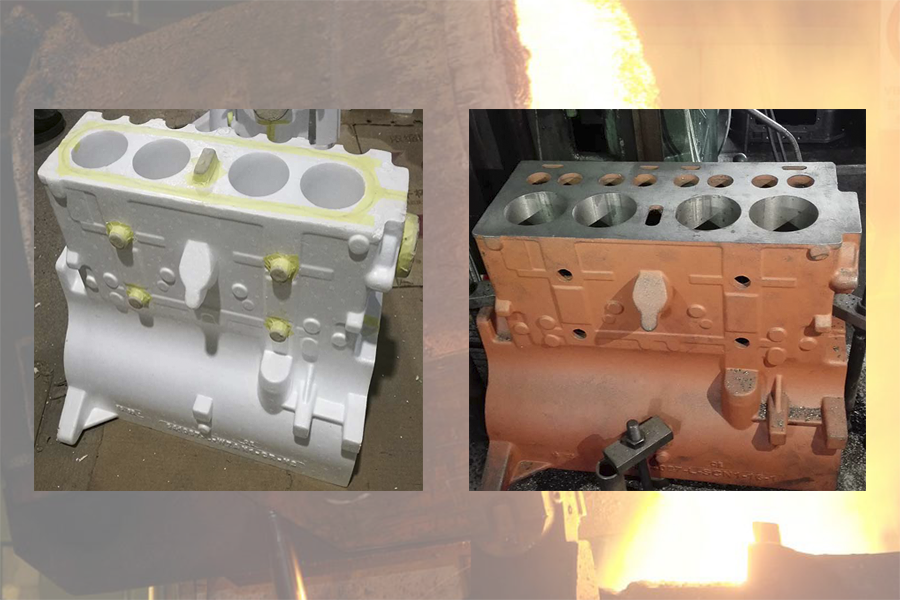

Ngenxa yolwazi lwethu olucebile kanye nemishini ehlelwe kahle, sinokukhetha okuhlukahlukeneizimboni ezahlukene. Esikukhethayo ikakhulukazi ukuphonsa isihlabathi, ukutshala imali, ukubunjwa kwegobolondo,ukukhishwa kwegwebu elilahlekile, i-vacuum cast kanye ne-CNC machining. Zombili izinsiza zangokwezifiso ze-OEM kanye ne-R&D ezimele ziyatholakala efektri yethu. Ubunjiniyela obuchwepheshile ukuncintisana kwethu okuyisisekelo.

Izinhlobo ezingaphezu kuka-100 zensimbi nama-alloys ziphonswa endaweni yethu yokusungula. Ikakhulukazi ziyi-gray cast iron,i-ductile cast iron, insimbi egayiwe ethambile ku-carbon steel,insimbi ye-alloy, insimbi engagqwali ne-aluminium nama-alloys ethusi. Ngakho-ke, kusukela kusevisi yethu, nobabili ningakhetha inqubo efanele yokusakaza nezinto zokwakha ukuhlangabezana nesicelo sakho senhlonipho. Abaningi bethuizingxenye zokusakaza ngokwezifisobahlinzeka ngozakwethu abahlukahlukene bemishini nezimboni abavela eYurophu, eMelika, e-Asia, e-Australia kanye nase-China.

Ukulingisa kwesihlabathi kuthatha umthamo omkhulu kunayo yonke enanini lesisindo kuzo zonke izinqubo zokulingisa. I-iron empunga, i-ductile iron, ithusi, insimbi ne-aluminium ama-alloys amakhulu.

Futhi okubizwa ngokuthi i-wax casting elahlekile noma ukusakaza okunembayo, ukusakaza kwe-investimenti kufinyelela ekunembeni okuphezulu kokubekezelelana kwejiyomethri kanye nobukhulu.

Ukubunjwa kwe-shell mold kusebenzisa isihlabathi esifakwe inhlaka ngaphambili ukwenza isikhunta. Ingasakaza kangcono kakhulu ngaphezulu kanye nobukhulu kunokubunjwa kwesihlabathi.

Ukukhishwa kwegwebu elilahlekile, okuphinde kubizwe ngokuthi ukubunjwa kwesikhunta esigcwele noma ukubunjwa kwesikhunta esingenazimbobo, kudlala indima ebalulekile ekubunjweni okukhulu nokuwugqinsi kodonga.

I-vacuum casting nayo ibizwa ngokuthi s V inqubo yokusakazwa, ukubunjwa kwesikhunta esivaliwe noma ukusakaza kwengcindezi engalungile. Kuncanyelwa komkhiqizo omkhulu futhi owugqinsi-odongeni.

Kwezinye izingxenye zensimbi ezinembayo, ukunemba kwe-CNC kuyinqubo ecishe igwenywe ngemva kokutholakala kokusakazwa okuqediwe.

| Amandla okusakaza e-RMC Foundry | ||||||

| Inqubo Yokusakaza | Amandla Wonyaka / Amathani | Izinto Ezibalulekile | Isisindo Sokusakaza | I-Dimensional Tolerance Grade of Castings (ISO 8062) | Ukwelashwa Kokushisa | |

| I-Green Sand Casting | 6000 | I-Cast Gray Iron, Cast Ductile Iron, Cast Aluminium, Brass, Cast Steel, Stainless Steel | 0.3 kg kuya ku-200 kg | I-CT11~CT14 | Normalization, Ukucisha, Tempering, Annealing, Carburization | |

| I-Shell Mold Casting | 0.66 lbs ukuya ku-440 lbs | I-CT8~CT12 | ||||

| I-Wax Investment Casting elahlekile | Ukusakaza Kwengilazi Yamanzi | 3000 | Insimbi engagqwali,Insimbi Yekhabhoni, Izingxube Zensimbi, Ithusi, I-Cast Aluminium, I-Duplex Stainless Steel | 0.1 kg kuya ku-50 kg | I-CT5~CT9 | |

| 0.22 lbs ukuya ku-110 lbs | ||||||

| I-Silica Sol Casting | 1000 | 0.05 kg kuya ku-50 kg | CT4~CT6 | |||

| 0.11 lbs ukuya ku-110 lbs | ||||||

| Ukusakaza Kwegwebu Elilahlekile | 4000 | I-Grey Iron, I-Ductile Iron, Ingxube Yensimbi, Insimbi Yekhabhoni, Insimbi Engagqwali | 10 kg kuya ku-300 kg | I-CT8~CT12 | ||

| 22 lbs kuya ku-660 lbs | ||||||

| I-Vacuum Casting | 3000 | I-Grey Iron, I-Ductile Iron, Ingxube Yensimbi, Insimbi Yekhabhoni, Insimbi Engagqwali | 10 kg kuya ku-300 kg | I-CT8~CT12 | ||

| 22 lbs kuya ku-660 lbs | ||||||

| I-High Pressure Die Casting | 500 | Ama-Aluminium Alloys, Ama-Zinc Alloys | 0.1 kg kuya ku-50 kg | I-CT4~CT7 | ||

| 0.22 lbs ukuya ku-110 lbs | ||||||