Njengenqubo yokukhiqiza eyisisekelo enomlando weminyaka engu-6000, ubuchwepheshe bokusakaza abugcini nje ngokuba nomlando omude, kodwa ngesikhathi esifanayo bubambe ubuchwepheshe obusha, izinto ezintsha kanye nezinqubo ezintsha ezithuthukiswe kwisayensi yesimanje ngesikhathi. Sinesibopho sokuqhubekisela phambili le mboni yokukhiqiza eyisisekelo. Amaphuzu alandelayo angeminye yemicabango yethu yenkambiso yentuthuko yesikhathi esizayo yenqubo yokuphonsa isihlabathi.

1 Ubuchwepheshe be-Foundry buyathuthukela ekongeni amandla nokonga impahla

Enqubweni yokukhiqiza yokuphonsa, inani elikhulu lamandla liyasetshenziswa enqubweni yokuncibilikisa insimbi. Ngesikhathi esifanayo, isidingo sezinto ezisetshenziswayo enqubweni yokukhipha isihlabathi sikhulu. Ngakho-ke, indlela yokulondoloza kangcono amandla nezinto zokwakha kuyinkinga enkulu ebhekene nezitshalo zokuphonsa isihlabathi. Izinyathelo ezisetshenziswa kakhulu zihlanganisa:

1) Yamukela ukubumba kwesihlabathi okuthuthukisiwe, ubuchwepheshe bokwenza ingqikithi nezinto zokusebenza. Kweinqubo yokukhiqiza isihlabathi, ukucindezela okuphezulu, ukucindezela okumile, ukucindezela komjovo kanye nemishini yokushaya umoya kufanele kusetshenziswe ngangokunokwenzeka. Futhi ngangokunokwenzeka ukusebenzisa isihlabathi esiziqinisayo,ukukhishwa kwegwebu elilahlekile, ukukhishwa kwe-vacuum nokusakazwa okukhethekile (okufanaukutshala imali, ukubunjwa kwensimbi yensimbi) nobunye ubuchwepheshe.

2) Ukubuyiselwa kwesihlabathi nokusetshenziswa kabusha. Lapho uphonsa izingxenye zensimbi ezingenayo insimbi, ukubunjwa kwensimbi nokubunjwa kwensimbi, ngokuya ngokushisa kwesihlabathi esishisayo, izinga lokutholwa kwesihlabathi esidala esivuselelwe ngomshini lingafinyelela ku-90%. Phakathi kwazo, inhlanganisela yokugaywa kabusha kwesihlabathi nokuvuselelwa kabusha okumanzi kuyindlela ekahle kakhulu futhi engabizi kakhulu.

3) Ukugaywa kabusha kwezinamathiselo. Isibonelo, uma i-casting i-de-cored ngendlela eyomile futhi i-adhesive ihlala esihlabathini, inqubo efanelekile ingenza i-adhesive isetshenziswe kabusha, ngaleyo ndlela yehlise kakhulu izindleko ze-adhesive.

4) Ukuvuselelwa kwesikhunta kanye nezinto zokubumba.

2 Ukuncipha kokungcoliswa kwemvelo noma ukungabikho kokungcoliswa

Indawo yokukhipha isihlabathi ikhiqiza amanzi angcolile amaningi, igesi engcolile kanye nothuli ngesikhathi sokukhiqiza. Ngakho-ke, i-Foundry akuyona nje indlu enkulu edla amandla, kodwa futhi umthombo omkhulu wokungcola. Ikakhulukazi eShayina, ukungcoliswa kwezakhiwo kubi kakhulu kunakwamanye amazwe. Phakathi kwazo, uthuli, umoya kanye nemfucuza eqinile ekhishwa ezitshalweni zokuphonsa isihlabathi yikona okubi kakhulu. Ikakhulukazi eminyakeni yamuva nje, izinqubomgomo zaseShayina zokuvikela imvelo ziye zaqina kakhulu, futhi izikhungo ezisunguliwe kuye kwadingeka zithathe izinyathelo ezisebenzayo zokulawula ukungcola. Ukuze kuzuzwe ukukhiqizwa okuluhlaza nokuhlanzekile kokusakazwa kwesihlabathi, izibophezelo eziluhlaza kufanele zisetshenziswe ngangokunokwenzeka, noma kusetshenziswe izibophezelo ezincane noma ezingekho. Phakathi kwezinqubo zokuphonsa isihlabathi ezihilelekile njengamanje, ukukhishwa kwegwebu elilahlekile, ukukhishwa kwenqubo ye-V kanye nokuphonsa kwesihlabathi se-sodium silicate kuhambisana nemvelo. Ngoba ukukhishwa kwegwebu elilahlekile kanye nokusakazwa kwenqubo ye-V kusebenzisa imodeli yesihlabathi esomile engadingi izibophezelo, kuyilapho ukuphonsa kwesihlabathi se-sodium silicate kusebenzisa izibophezelo eziphilayo.

3 Ukunemba okuphezulu kwe-dimensional kanye ne-geometrical kokulingisa

Ngokuthuthukiswa kwenqubo yokunemba yokwenza yokuphonsa izikhala, ukunemba kwe-gemometical kanye ne-dimensional kokwakheka kwengxenye kuyathuthuka ukusuka eduze kokwakheka kwenetha kuya ekubunjweni kwenetha kwe-forminig, okungukuthi, cishe akukho ukwakheka kwemajini. Umehluko phakathi kokungenalutho kokulingisa kanye nezingxenye ezidingekayo uya ngokuba mncane futhi ube mncane. Ngemva kokuba ezinye izikhala zakhiwe, ziye zasondela noma zafinyelela ukuma nobukhulu bokugcina bezingxenye, futhi zingahlanganiswa ngokuqondile ngemva kokugaya.

4 Amaphutha amancane noma angekho nhlobo

Enye inkomba yokulunywa kwe-casting kanye nezingxenye ezakha izinga yinombolo, usayizi kanye nokulimala kokulimala kokuphonsa. Ngenxa yokuthi ukusebenza okushisayo kanye nezinqubo zokuphonswa kwensimbi ziyinkimbinkimbi kakhulu futhi zithinteka yizici eziningi, ukukhubazeka kokuphonsa kunzima ukukugwema. Nokho, amaphutha ambalwa noma awekho nhlobo ayindlela yesikhathi esizayo. Kunezinyathelo ezimbalwa ezisebenzayo:

1) Yamukela ubuchwepheshe obuthuthukisiwe ukuze ukhuphule ukuminyana kwesakhiwo sengxubevange futhi ubeke isisekelo sokuthola ukusakaza komsindo.

2) Sebenzisa isofthiwe yokulingisa yokulingisa inqubo yangempela yokulingisa esigabeni sokuklama kusengaphambili. Ngokuya ngemiphumela yokulingisa, ukwakheka kwenqubo kuthuthukisiwe ukuze kubonakale impumelelo yokubumba ngesikhathi esisodwa kanye nokuhlolwa kwesikhunta.

3) Qinisa ukuqapha inqubo futhi wenze imisebenzi ngokuqinile ngokuhambisana nemiyalelo yokusebenza enqunyiwe.

I-4) Qinisa ukuhlolwa okungonakali enqubweni yokukhiqiza, thola izingxenye ezingajwayelekile ngesikhathi futhi uthathe izinyathelo ezihambisanayo zokulungisa nezokuthuthukisa.

5) Thola inani elibalulekile lesici ngocwaningo nokuhlola ukuphepha nokuthembeka kwezingxenye.

5 Ukukhiqizwa okungasindi kwama-castings.

Ekwenziweni kwezimoto zabagibeli,amaloli, kanye nezinye izinto zokuhamba, indlela yokunciphisa isisindo sezingxenye ngenkathi uqinisekisa amandla ezingxenye kuwumkhuba osobala. Kunezici ezimbili eziyinhloko zokufeza ukunciphisa isisindo. Enye iwukusebenzisa izinto ezingavuthiwe ezilula, kanti enye iwukunciphisa isisindo sezingxenye kusukela ekwakhiweni kwesakhiwo sezingxenye. Ngobaukukhishwa kwesihlabathiube nokuguquguquka okukhulu ekwakhiweni kwesakhiwo, futhi kukhona nezinto eziningi zensimbi zendabuko nezintsha ongakhetha kuzo, ukubunjwa kwesihlabathi kungadlala indima enkulu ekukhiqizeni okungasindi.

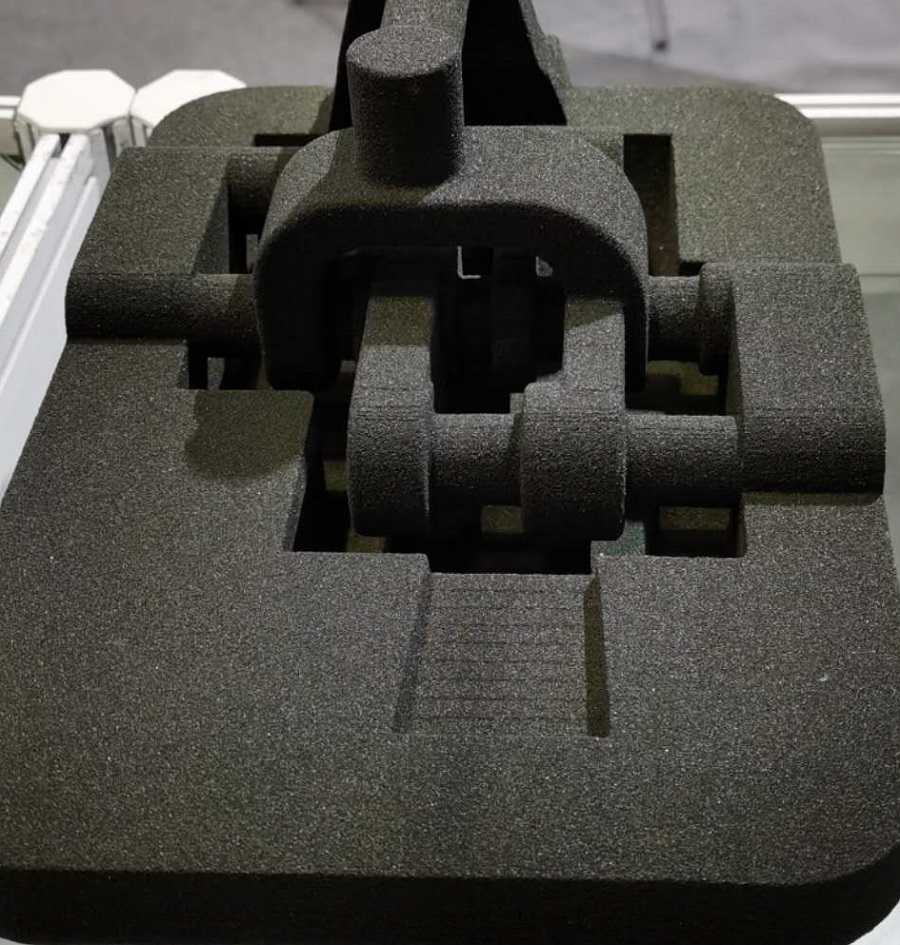

6 Ukusetshenziswa kobuchwepheshe obusha njengokuphrinta kwe-3D ekwenzeni isikhunta

Ngokuthuthuka nokuvuthwa kobuchwepheshe bokuphrinta be-3D, bubuye busetshenziswe kabanzi emkhakheni wokulingisa. Uma kuqhathaniswa nokuthuthukiswa kwesikhunta sendabuko, ubuchwepheshe bokuphrinta be-3D bungakhiqiza ngokushesha isikhunta esidingekayo ngezindleko eziphansi. Njengobuchwepheshe be-prototyping obusheshayo, ukuphrinta kwe-3D kunganikeza ukudlala okugcwele ezinzuzweni zakhona ekukhiqizweni kwesilingo sesampula kanye nezigaba ezincane zeqoqo lokulingisa.

Isikhathi sokuthumela: Dec-25-2020