Ukuqondisa kokulingisa, okubuye kwaziwe ngokuthi ukulungisa noma ukulungisa, kuyisinyathelo esibalulekile enqubweni yokukhiqiza ukuze kuqinisekiswe ukuthi izingxenye zensimbi ezisansimbi zihlangabezana nokucaciswa kobukhulu obunembe kanye nobuqotho besakhiwo.

Izindlela Zokuqondisa

Kunezindlela eziningana ezisetshenziswayo ukuze kuqondiswe ukulingisa, ngayinye ilungele izinhlobo ezahlukene zezinto kanye nokubunjwa kokulingisa. Izindlela eziyinhloko zihlanganisa:

Ukuqondisa Kwemishini: Lokhu kubandakanya ukusetshenziswa kwamandla angaphandle kusetshenziswa amathuluzi emishini nemishini. Amasu anjengokucindezela, ukugoba, nokushaya ngesando avamile. Ukuqondisa ngemishini kusebenza ikakhulukazi ekulingiseni okukhulu futhi okuqinile.

Ukuqondisa Okushisayo: Kule ndlela, ukushisa kusetshenziswa ezindaweni ezithile zokusakaza ukuze kubangele ukwanda noma ukufinyezwa kwe-thermal, ngaleyo ndlela kulungiswe ukuhlanekezela. Le ndlela inenzuzo kuma-castings angakwazi ukuqhekeka noma ukuphuka ngaphansi kwengcindezi yemishini.

I-Hydraulic Straightening: Ngokusebenzisa umshini wokunyathelisa we-hydraulic, le ndlela isebenza ngokucindezela okulawulwayo ukuze kuqondiswe ukusakaza. Inikeza ukunemba okuphezulu futhi ifanele izimo ezithambile neziyinkimbinkimbi ezidinga ukuphathwa ngokucophelela.

Izindlela Zokuhlanganisa: Ngokuvamile, inhlanganisela yokuqondisa komshini nokokushisa kusetshenziswa ukuze kuzuzwe imiphumela efiselekayo, ikakhulukazi ekubunjweni okunejiyometri eyinkimbinkimbi kanye nezakhiwo zezinto ezibonakalayo.

Ukuhlukaniswa kanye Nokukhethwa Kwezisetshenziswa Zokuqondisa

Ukukhethwa kwemishini yokuqondisa kuncike ezintweni eziningana, okuhlanganisa uhlobo lokubunjwa, izakhiwo zezinto ezibonakalayo, kanye nezinga lokuguqulwa. Izinhlobo eziyinhloko zemishini yilezi:

Amathuluzi Okuqondisa Ngesandla: Amathuluzi alula njengezando, ama-anvils, nokucindezela okubanjwa ngesandla kusetshenziselwa ukulungisa izinto ezincane noma ezincane. Badinga opharetha abanamakhono ukuze bathole imiphumela enembile.

Imishini yokunyathelisa: Lokhu kuhlanganisa ukucindezela kokuguqula, ukucindezelwa ngezikulufu, nokucindezela kwe-eccentric. Zifanele ukulingisa okuphakathi nendawo kuya kokukhulu futhi zinikeza ukusetshenziswa kwamandla okungaguquki. Imishini yokunyathelisa yemishini ikhethwa ngenxa yokwethembeka kanye nokusebenza kalula.

Ama-Hydraulic Presses: Le mishini yokunyathelisa inikeza amandla aphezulu kanye nokulawula okunembile phezu kwesicelo sokucindezela. Zilungele ukuqondisa ukulingisa okukhulu, okusindayo, nokuyinkimbinkimbi. Imishini yokunyathelisa ye-Hydraulic ingafakwa ama-dies and fixtures ahlukahlukene ukuze ikwazi ukuthwala ubujamo nosayizi abahlukene.

Izithando Zokushisa Zokushisa: Isetshenziselwa ukuqondisa okushisayo, lawa ma-furnaces avumela ukushisa okulawulwayo kwama-castings ukuze kubangele ukukhululeka kwengcindezi nokulungiswa kokuguqulwa. Zibalulekile ekubunjweni okungakwazi ukubekezelela amandla omshini.

Ukuqondisa Kufa

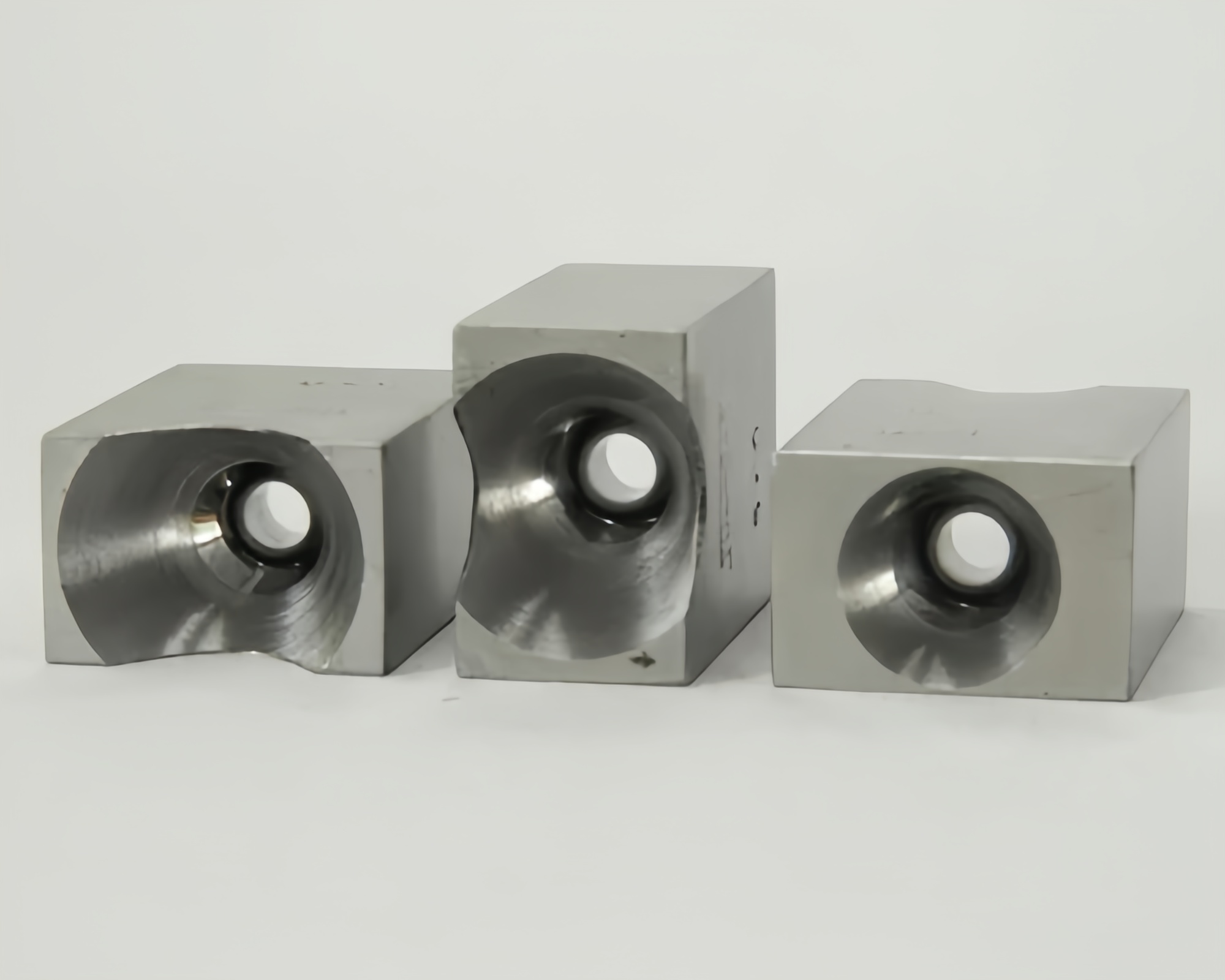

I-Straightening dies, eyaziwa nangokuthi i-correction dies, ingamathuluzi aklanywe ngokukhethekile asetshenziswa ngokuhambisana nomshini wokunyathelisa ukuze kubunjwe kabusha ngokunembile ukulingwa okugogekile. Ahlukaniswa ngokuya ngomsebenzi wawo kanye nohlobo lokulingisa asetshenziselwa wona:

I-Flat Dies: Lezi zisetshenziselwa ukuqondisa izindawo eziyisicaba namachopho. Alula ekwakhiweni kwawo kodwa asebenza kahle ekulungiseni ukuhlanekezela okuhleliwe.

Ukwakha Ukufa: Idizayinelwe ukufanisa i-contour yokulingisa, lezi zifa zisetshenziselwa ukulungisa izimo eziyinkimbinkimbi namajika. Zenzelwe ngokwezifiso imiklamo ethile yokusakaza futhi ziqinisekisa ukunemba ekuqondiseni.

Ukusekela Kufa: Lezi zifa zihlinzeka ngokusekela nokuzinzisa ukusakaza phakathi nenqubo yokuqondisa. Zibalulekile ekuvimbeleni ukuwohloka okwengeziwe noma ukulimala ngesikhathi sokulungiswa.

Ukukhethwa kwefa lokuqondisa kubalulekile ekuzuzeni imiphumela oyifunayo. Kufanele ifane nokulingisa's ijiyomethri kanye nemvelo yokuhlanekezela ukunikeza ukulungiswa okuphumelelayo ngaphandle kokudala ingcindezi eyengeziwe noma umonakalo.

Ukuqondisa kokulingisa kuyinqubo ebalulekile ekuqinisekiseni ikhwalithi nokusebenza kwezingxenye zensimbi. Ngokusebenzisa izindlela ezifanele, ukukhetha okokusebenza okufanele, nokusebenzisa imishini yokuqondisa eqondile, abakhiqizi bangalungisa ama-deformation futhi bakhiqize ama-castings ahlangabezana nezindinganiso ezifanele. Lokhu akugcini nje ngokuthuthukisa ukusebenza komkhiqizo wokugcina kodwa futhi kwandisa impilo yawo yesevisi, kuqinisekisa ukwethembeka nokwaneliseka kwamakhasimende.

Isikhathi sokuthumela: Oct-18-2024